October 23, 2015

Sponsored Content

There are multiple reasons for tractor equipment failures. One of the most common is that moving parts are not lubricated properly. Inadequate lubrication makes tractors vulnerable to oxidation, wear, brake chatter, erosion, corrosion and the effects of cold temperatures. However, quality lubricants with advanced additive packages are available to help farmers prevent these conditions, protecting equipment, improving performance and extending tractor life.

Today’s tractors are used for farming and non-farming applications – including use by recreational farmers, municipalities and golf courses – but to the dedicated farmer, the tractor is a critical piece of equipment and a capital investment. With proper maintenance, the average working life of a farm tractor is about 15 years.

Quality tractor fluids containing chemical additive packages protect transmissions, hydraulic systems, brakes, clutches, pumps and other moving parts on tractors, safeguarding the farmer’s investment and livelihood. Because quality fluids are used for multiple applications on a tractor, farmers can simplify maintenance and reduce the number of lubricants kept in their farm’s inventory.

However, selecting the best tractor fluid is an important decision, as they are not all created equally. Some fluids are on the market with low performing additive packages that can result in mechanical problems that lead to increased downtime and shorter equipment life. The discounted price is attractive to some buyers, but the long-term maintenance and repair costs attributed to substandard lubricants can significantly outweigh that initial lower cost. Quality tractor fluids are higher in price, but they are the preferred choice for engaged farmers who recognize the value and benefits that quality fluids provide.

“A tractor is a major investment for a farmer, and one of the most important pieces of equipment on the farm,” said Jim Turner, owner of a dealer and repair shop—Jim Turner Sales located in Clymer, NY. “Saving a few dollars on a bargain fluid is not what they want to do. I always make sure my customers understand the benefits of quality fluids and encourage them to purchase the best. A quality fluid protects their investment, extends tractor life and reduces the chances of costly repairs.”

Protection: Quality Lubricants Have What it Takes

High-performance tractor fluids contain the right chemical additive packages to effectively protect gears, clutches and pumps by providing oxidation resistance, anti-wear protection, water tolerance and enhanced performance in temperature extremes and harsh conditions. Here is a checklist that addresses the differences between high-quality and budget-priced fluids.

Oxidation

A dramatic difference when comparing a housing with oxidation build up and a clean part protected with quality tractor hydraulic fluid.

A dramatic difference when comparing a housing with oxidation build up and a clean part protected with quality tractor hydraulic fluid.

Oxidation causes the formation of sludge deposits and the thickening of fluids, which reduces performance and shortens the life of any tractor. Oxidation protection characteristics provided by the additives in high performance tractor hydraulic fluids keep parts cleaner. Eliminating sludge means better overall performance, gear protection and reduced brake noise. And, clean fluids don’t have to be replaced as often.

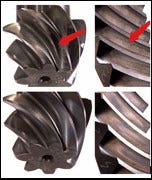

Excessive Wear

High-performance fluids provide a dual excessive wear protection system for gears, bearings and the soft, yellow metals in hydraulic pumps. Without the right additives, a lubricant’s load carrying, anti-wear and extreme pressure characteristics fail and result in severe ridging, visible wear and scoring on gear parts.

Corrosion

Damage to pinion and ring gear surfaces results if not protected by high-performance fluids with protective additives.

Damage to pinion and ring gear surfaces results if not protected by high-performance fluids with protective additives.

Water is harmful to a tractor’s seals, valves and yellow metal components in pumps and valves. High quality tractor fluids prevent the water contamination that results in corrosion and erosion. Corrosion often leads to sluggish tractor performance and potential hydraulic pump failure. Water that mixes with lower quality tractor fluids to form a corrosive mixture erodes the yellow metal on hydraulic pumps, causing deep scratches on the pump’s brass piston shoes.

High performing tractor fluids with additives provide high water tolerance, enabling the fluid to protect parts from corrosion and erosion in the presence of water. This optimizes tractor performance and reliability.

Brake Chatter

Lower-quality fluids do not interact with friction materials as effectively as premium oils with chemical additive packages designed to ensure optimal friction performance. Lack of friction protection causes a screeching noise in wet brakes and reduces brake performance. High performance fluids improve braking capacity and prevent brake chatter for greater operator safety and comfort.

Cold Temperature Failure

High performing fluid protects the yellow piston shoes from erosion on this hydraulic pump. The brass piston shoes are completely scratch and erosion free

High performing fluid protects the yellow piston shoes from erosion on this hydraulic pump. The brass piston shoes are completely scratch and erosion free

Quality tractor fluid products provide excellent viscosity control over a wide operating temperature range. Additive packages keep fluids from becoming thicker after being exposed to high temperatures for prolonged periods of time. Thicker fluids contribute to increased pump wear in a farm tractor.

High-performance fluids are important to operation in cold temperatures as well. Without additives, some fluids take longer to provide an adequate lubricant film to protect metal parts within the hydraulic system from grinding against each other. Superior fluids are formulated for performing in temperatures below freezing and assuring instant lubrication of moving parts for the tractor’s transmission, steering, braking and hydraulic pump functions.

The Price of Performance

Lower tier fluids run from $4 to $6 per gallon with specialized OEM branded fluids from $12 to $18 per gallon. An array of fluids of varying quality and price fall in between. While it may seem like quite a bargain, the use of sub-standard hydraulic fluid often backfires, resulting in damaged equipment, disrupted work schedules and needless repair bills. It is important to understand that the difference between lower quality and high-performance tractor fluids shouldn’t be judged on price alone.

High-performance tractor fluid is the best way for farmers to maximize years of reliable, trouble-free tractor life, increased productivity and profit. Tractors, combines and other agricultural equipment are designed and built to perform in harsh conditions, and quality tractor fluids protect the hydraulic systems that power them.

Why High Quality Fluids Matter

High performing tractor hydraulic fluids with advanced additive packages provide oxidation resistance, anti-wear protection, water tolerance and performance in temperature extremes. Farmers should look for fluid products that identify these attributes right on the product’s label. A quality tractor fluid is:

Specifically designed for farm tractors and other off-highway equipment and should list OEM specifications;

Multi-purpose, enabling lubrication of a tractor’s transmission, final drives, clutches, wet brakes and hydraulic systems;

An excellent wear-protection fluid that provides anti-wear properties for clutches, gears and hydraulic pumps;

Designed to prevent brake chatter;

A high-water tolerance product that protects parts from corrosion and erosion when contaminated with water;

Suitable for year-round use in extreme hot and cold temperature ranges.

Bargain-priced tractor hydraulic fluids are often missing the anti-wear additives, detergents, friction modifiers, and viscosity index improvers that protect tractor hydraulic systems and moving parts. These low-quality fluids often fail oxidation, gear wear, cold temperature and viscosity tests. If they can’t perform in the laboratory, they certainly won’t deliver on the farm.

In order to help you select fluids you can trust we launched the tractorlife.com Authenticated mark. Fluids endorsed by this mark meet and often exceed OEM credentials, providing you optimal protection against wear, rust, oxidation, brake chatter, extreme temperatures and, ultimately, premature equipment failure. Find out more now!

© 2015, tractorlife.com

You May Also Like