Proper handling of animal health products is key to ensuring their efficacy, says Dr. Brian Lubbers, K-State beef cattle veterinarian.

Lubbers spoke on a recent episode of the K-State Beef Cattle Institute’s “Cattle Chat” podcast.

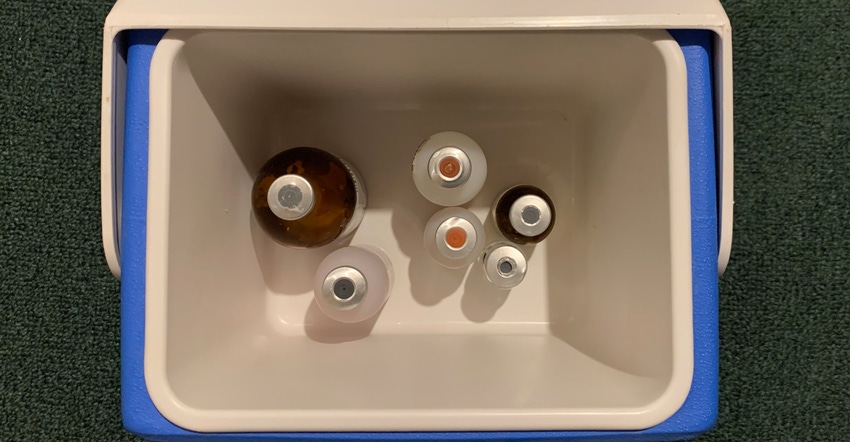

1. Maintain temperature. This is probably the key factor to consider, whether working cattle in spring or fall, Lubbers says. The easiest way to maintain temperature is to keep vaccines in a cooler when you’re processing cattle. Either add an ice pack or a heat pack, depending on the ambient temperature.

2. Avoid contamination. Lubbers says dirty needles can drag fungus or bacteria into the bottle if the lid or needle is dirty. That can cause vaccine-site reactions and abscesses in the processed cattle. He advises to puncture the lid once with a dedicated clean needle, drawing up the vaccine, and then switching the needle on the syringe to lower the contamination risk.

3. Avoid wasting product. Once a bottle has been opened or punctured, the vaccine has a limited shelf life, Lubbers says. Plan ahead and know how many cattle you’ll be working to avoid wasting product.

“A lot of these principles also apply to other animal health products as well,” Lubbers says. Product labels include all the information users need to make sure they’re handling products safely and efficiently, he says. And, Beef Quality Assurance program guidelines also provide additional resources for cattle producers on using products safely and effectively.

To learn more, ask your veterinarian or listen to the "Cattle Chat" podcast.

Kansas State Research and Extension contributed to this article.

About the Author(s)

You May Also Like