The center pivot has been around for nearly 50 years. Until recently, it's been a machine that has been solely used to irrigate crops. In the past several years, companies have taken steps to turn that machine into a fully autonomous crop management system.

In November, Lindsay Corp. announced its Smart Pivot system, a product of a partnership between Lindsay, Microsoft Azure and aerial imagery provider Taranis. The Smart Pivot is an autonomous crop management system that combines satellite imagery, aerial imagery, and pivot-mounted sensors to detect anomalies in crop fields, help make irrigation scheduling decisions and reduce the pivot's operational downtime.

"Moving beyond traditional water application and management, the Smart Pivot combines advanced agronomic capabilities with state-of-the-art machine health features, to provide real-time crop health and operational support throughout the growing season," says Wade Sikkink, global director of product management at Lindsay. "In short, this is the pivot of the future."

Lindsay describes the Smart Pivot as the merging of two smart streams. This includes a joint development with Microsoft Azure to use sensors to collect data related to machine health and feeding that data back to a centralized location on the pivot point, and using edge-of-field computing and advanced algorithms to send that information to Lindsay's FieldNet platform.

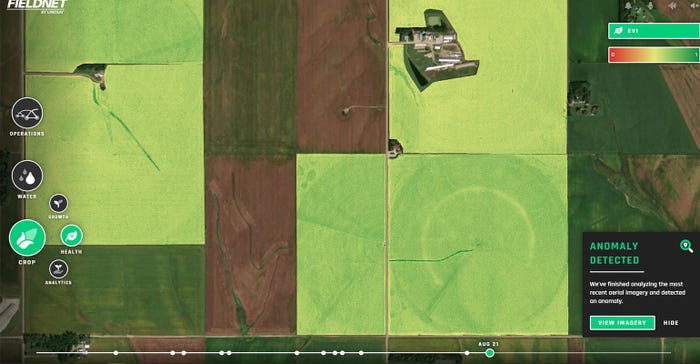

Meanwhile, through a partnership with Taranis, Lindsay is using aerial imagery and pivot-mounted multispectral imaging sensors, optical still cameras and video cameras — along with Lindsay's FieldNet Advisor platform — to monitor crop growth stages and detect and identify agronomic anomalies in the field. These issues might include weed, pest and disease pressure and nutrient deficiencies. The Smart Pivot also calculates resource savings in real time.

"Think of it this way: The pivot's a robot on alert 24/7, effectively seeing everything that's going on in every part of your field, instantly scaling up your ability to identify and correct issues before they become problems," Sikkink says. "The Smart Pivot is self-aware, monitoring health at the component level, helping to identify performance anomalies that could lead to downtime."

Networked pivot

Mark Miller, director of controls and IIoT engineering at Lindsay, explains the Smart Pivot is a platform of connected sensors, imagery, inputs and controls integrated with analytics — what Lindsay calls a networked pivot.

"What we've done here is we've fully networked the length of the pivot using minimal wiring all the way down the spans to enable collection of data from various sensors," Miller says. "A typical span cable has been replaced with three-phase power wires and an ethernet cable. This allows us to obtain data about how the pivot is operating, about the field and the environment. It also enables more precise tower controls that help us better manage the entire machine."

Through a partnership between Lindsay Corp. and Taranis, the Smart Pivot uses satellite imagery, aerial imagery collected by UAVs, and pivot-mounted sensors and cameras to detect and identify the causes of anomalies.

Albert Maurin, Lindsay software product manager, explains that the Smart Pivot uses satellite imagery to detect where an anomaly is occurring, followed by deploying a pivot-mounted sensor or camera or unmanned aerial vehicle for higher-resolution images and analysis to identify the specific cause of the anomaly.

For example, diseases such as white mold in soybeans are an example of an issue that can become more problematic if not detected quickly.

"This allows us to scout the entire field much more quickly, much more efficiently, and send that information back to the user, so that if you do have white mold or another disease or pest, you could spot-treat it before it becomes really devastating in the yield map and reduce your input costs," Maurin says.

This also includes issues such as plugged sprinklers, poor spray patterns and ponding in the field. Ultimately, this helps reduce downtime. Take a flat pivot tire, for example.

"We can look at a trend in the data, and if we were at 15 psi, and then at 14, and then 13, we know we're trending downward and have a slow leak in our tire," Maurin says. "We can move the pivot to the service road automatically. Now when we go to replace that tire, it becomes a one- or two-hour fix versus an all-day fix with the pivot stuck out in the middle of the field."

Driven by feedback

Maurin explains that the Smart Pivot concept was driven by feedback from growers.

"It was a lot of time spent out with growers in the field and listening to grower feedback," he says. "That's really where we started looking at what we could do from a digital perspective and change the way the pivot operates today. We also leveraged our internal capabilities with our own internal IoT and electrical and hardware engineers to take customer feedback and engineer a solution around it."

Brian Magnusson, Lindsay vice president of the Americas, says this winter, Lindsay is focusing on incorporating feedback from growers as it works toward a commercial release. This spring, in North America and Brazil, Lindsay is working with growers in an initial beta launch.

"We will use insights gathered during this next growing season in the Northern Hemisphere to extensively test and refine the weed, pest and disease detection capabilities and expect to bring them more broadly to market by the spring of 2022," Magnusson says.

About the Author(s)

You May Also Like