Since dicamba-tolerant and 2,4-D-tolerant crops hit the market several years ago, most producers have selected one technology or the other for their cotton rotation. Sure, you’ll commonly see Xtend (dicamba-tolerant) soybeans with Enlist (2,4-D-tolerant) cotton. But because of XtendFlex cotton’s extreme sensitivity to 2,4-D herbicides, it’s rare to see producers mix cotton varieties from the two technologies for fear of damaging their own crops through misapplication or sprayer contamination.

Rare, but not impossible.

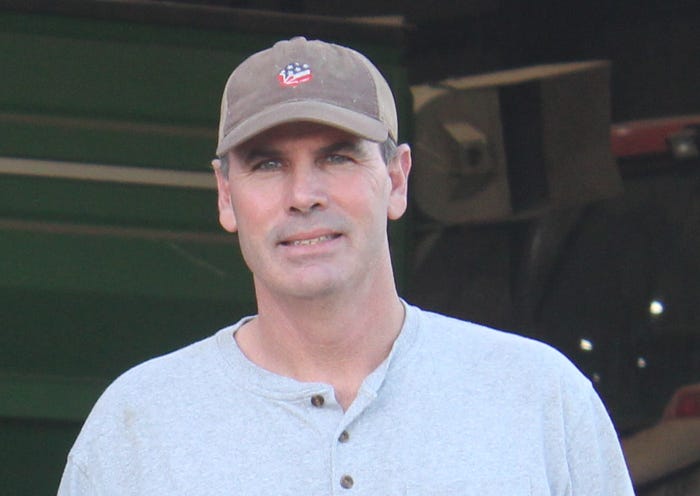

“It can work, but it will require more planning, and everyone in your operation has to be on the same page,” said Gem Mitchell, a row-crop producer near Bolivar, Tenn.

Mitchell, who farms a little over 3,000 acres with his father and sons, has grown Enlist cotton with Xtend soybeans since the auxin-tolerant crops became available. In 2020 he added some XtendFlex cotton acres to his crop mix for the first time.

“I refused to do it prior to this year, and I’ll be honest, we were all scared to death,” Mitchell recalled. “But we wanted to try the different chemistries. We wanted to see the different varieties. We have two sprayers, and our fields are scattered across the county. With that setup we thought we could make it work.”

Across town, fellow Bolivar producer Andy Shelton also experimented with mixing herbicide technologies in his cotton acres. Like Mitchell, Shelton primarily grows Enlist cotton, but was interested in trying new varieties. He was also keen on avoiding potential drift issues when a neighbor planted XtendFlex cotton directly adjacent to one of his fields.

“When we’re spraying those auxin herbicides, I stay a nervous wreck, just because I worry more about my neighbor than I do myself,” Shelton said. “Drift is my biggest fear.”

Mitchell and Shelton say mixing technologies on the same farm requires increased diligence in planning, record keeping, and especially sprayer clean out. But despite the extra effort involved, both producers spoke positively about the outcome.

“It’s very possible to do. We will probably do it again next year, just because I liked some varieties on both sides of the technology,” Shelton said. “We don’t want to miss out on a variety that could be beneficial to us just because it requires a little more work.”

Location, location, location

If producers do want to try mixing these technologies, having them in close proximity is going to be extremely difficult, according to Larry Steckel, Extension weed specialist with the University of Tennessee Institute of Agriculture.

“Keeping them separated will help the farmer and the crew keep track of what technology is where,” Steckel said. “So, the layout of your farm may determine whether or not this would even be a viable option for you.”

Mitchell said that was a helpful strategy for his operation. He planted Enlist cotton on one end of the county and Xtend cotton on the other.

“That way we have no doubt where it’s at and what we need to spray when we get there,” he said. “I would never put any close together because of the danger of someone making a mistake.

Likewise, Shelton, who also farms just over 3,000 crop acres with his father and son, separated the different auxin technologies for ease of management. Neither producer reported issues with drift, although they say that’s due to strict adherence to herbicide spray guidelines.

“I’m very strict about wind and weather conditions when we’re spraying,” Mitchell said. “If the wind gets up, we shut our sprayers down. If the wind is blowing the wrong direction that day, we go somewhere else and spray. We keep wind meters in our sprayers and monitor through different apps.”

Mitchell’s son Clay can vouch for his dad’s meticulous observance of auxin herbicide labels. “If we’re in the sprayer he’s calling us and reminding us to watch the wind speed. The last thing he says as we leave the shop is ‘Remember to keep your booms low.’”

The potential for dicamba or 2,4-D volatility also continues to be a concern for many producers. In 2021, a volatility reduction agent must be added to applications of over-the-top dicamba. Steckel said initial UTIA evaluations of the new buffering agent Sentris have shown a clear benefit when tank mixed with Engenia herbicide in reducing loss through volatilization.

“The early research results are promising,” Steckel said. “If these volatility reduction agents can decrease volatility in the field at the rate we’re seeing in humidome studies, growers could potentially have more flexibility in the varieties they plant and where they plant them.”

Tank clean out

Self-inflicted damage through a contaminated sprayer is a huge deterrent for mixing auxin technologies on the same farm. For those wanting to try Xtend and Enlist cotton, Shelton cautions be prepared to spend a lot of time washing out your spray tank.

“We were so careful about this because of contamination,” Shelton said. “If you want to do it right, the tank clean out does take a lot of time. We would triple rise, and a lot of times we would triple rinse twice. Clean all the nozzles, screens and filters and let the tank cleaner sit in the tank overnight.”

“I like ammonia as a cleaning solution, but household ammonia was hard to find this year due to COVID, so we went with a higher-priced tank cleaner.”

Shelton said he and his son, Peyton, do all the spraying and planting on his operation. This year they started spraying in the Enlist cotton, then moved to Xtend.

“We do that so we can jump into our Xtend soybeans and keep spraying without having to clean out again,” Shelton said. “We tried to do it in an organized process. Sometimes with weather and being spread out, you might not be able to do that, but it worked out for us this year.”

Although he’s using two sprayers, Mitchell said he still spent his summer washing out his sprayer constantly. Like Shelton, a majority of his cotton acres were Enlist, so that’s where he started spraying before moving to XtendFlex cotton and Xtend soybeans.

“We would do an extensive washout every time — pop the caps off our booms, blow the tips out, wash them —and park that sprayer with the cleaning solution in it overnight, so we’d be sure to get a thorough cleanout,” Mitchell said.

While Mitchell said two sprayers are not a necessity when mixing auxin technologies (his friend, Shelton is doing it successfully with one), it was a huge benefit.

“It helped us more on timeliness than anything,” Mitchell said. “We could make one sprayer work, but being so timely has been the key to our pigweed management.”

Good planning

When it came to weed control neither producer reported big differences between the two auxin herbicides.

“Both did a good job for us,” Shelton said, “but we were really timely. It’s critical to get those applications out timely.”

Mitchell echoed Shelton’s position. “We saw really good control with both products. Our crops were pretty clean all the way through. We haven’t seen auxin slippage yet. I’m sure it’s coming, but we haven’t seen it yet, and I think that goes back to being timely.”

With little room for error, record keeping is key. Both operations employ Climate FieldView, a digital agricultural tool, to document planting dates, spray applications and keep track of environmental conditions.

Was it worth it?

Mixing cotton auxin technologies is not for everyone as Steckel strongly cautions.

“A grower needs to stay on his toes to do this properly,” Steckel said. “Producers need to be actively involved in the day-to-day activities to make this work.”

But for those willing to take the risk and put in the extra effort, if could be an advantageous move. So, our final question to Shelton and Mitchell: was it worth it?

“It is a little more work,” said Shelton, “but we don’t want to shut the door on something that might benefit us. Even though those auxins are close kin, I think it does do well to rotate them and put a different chemistry out there.

“There are so many varieties with good qualities, and we never want to limit ourselves on yield.”

“We’ll probably continue doing it,” said Mitchell, who’s considering adding Enlist soybeans to his 2021 crop mix. “I’ve been farming long enough to know you’ve always got to be looking ahead and always willing to take a little risk.”

About the Author(s)

You May Also Like