September 16, 2022

Generally speaking, soybean producers are always looking for ways to expedite harvest operations, so that wheat planting and fall tillage operations can be performed under optimum conditions in a timely manner.

There are several options for speeding up soybean harvest operations:

Increase combine ground speed when possible. When conditions are suitable, increasing your ground speed may be an easy way to increase harvest capacity when faced with a short harvest window. Increasing harvest losses and plugging the combine are the biggest potential downsides of this option.

Increasing combine ground speed increases the potential for gathering losses, and threshing and cleaning losses. Gathering losses because of higher speeds occur when the cutter bar rides over plants before cutting them off, stripping pods from the plants or leaving them attached to the stubble.

Frequent and careful “fine-tuning” of reel speed and position are necessary at higher ground speeds. Tall, uneven stubble and loose beans and pods on the ground are indicators ground speed is too fast.

Threshing losses occur when the combine’s threshing and separating capacity are exceeded. Draper heads optimize combine capacity and minimize threshing losses by providing more uniform feeding than auger heads.

Stopping periodically to check for harvest losses is always important. However, this is even more important at higher ground speeds. Even harvest losses of 2 bushels per acre add up quickly.

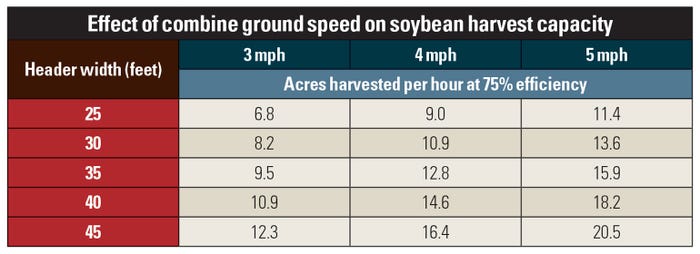

The table shows that operating a combine equipped with a 30-foot header at 5 mph instead of 3 mph increases capacity by 5.4 acres per hour. However, assuming additional losses of two bushels per acre and a market price of $14.40 per bushel, the lost revenue is $392 per hour (13.6 acres per hour x 2 bushels per acre lost per acre x $14.40 per bushel).

Rank your fields by harvest priority. Prioritize the harvest order for all your fields. Consider soybean maturity or moisture content, field size, soil type, field drainage, soil moisture, lodging, shattering, and location when planning your harvest schedule.

Consider harvesting soybeans at higher moisture levels. Given the current market price, harvesting soybeans at 15% to 16% moisture is more profitable than harvesting overly dry soybeans at 11% moisture. This is true even when the beans are delivered directly to the elevator, and drying charges are increased by 30% over those incurred in 2021.

The plants may be tough and difficult to cut, so it is critical to have the cutter bar in top condition. All knife sections should be sharp and tight, and all guards should be properly aligned to ensure optimum cutting. The gap between the sickle and the hold-downs should be about the thickness of a business card.

Harvesting at a slight angle to the rows will improve feeding and distribute wear evenly across the knife sections and guards. Reducing your ground speed may be necessary to improve cutting and provide more uniform feeding into the combine.

Combines equipped with draper heads or air-assisted reels are more efficient at transporting moist soybean plants across the head and into the feeder housing, extending the harvest window each day.

Threshing and cleaning high-moisture soybeans is challenging. Achieving uniform feeding and keeping the threshing cylinder or rotor full are the first steps to improving threshing. If too many soybeans fail to thresh from the pods, try reducing the concave clearance first.

This may increase plugging problems at the cylinder or rotor if the straw is tough. If plugging is a problem or unacceptable threshing occurs, increase the speed of the cylinder or rotor.

Make incremental adjustments and check threshing performance and grain quality after each adjustment. It can be a balancing act to find the correct cylinder or rotor speed and concave clearance settings that provide acceptable threshing without causing excessive split or crushed beans.

Increased threshing and cleaning losses are more likely to occur when harvesting high-moisture soybeans because of the tough stems and pods and softer seeds. Evaluate grain quality, gathering losses, and threshing and cleaning losses when harvesting soybeans at higher moisture levels.

Reduce combine unloading time. Consider using a grain cart to improve harvest efficiency by reducing unloading time. Unloading on the go can increase harvest capacity by 1 to 4 acres per hour over the figures listed in the table.

The downsides of unloading on the go are increased costs (fuel, labor and machinery) and a greater potential for compacting the soil. Because the first pass causes most of the damage, soil compaction because of the grain cart can be significantly reduced if the grain cart travels in the combine’s tire tracks.

If unloading on the go is not an option, reduce the combine’s drive time (distance) to the truck or wagon to unload. Reducing the drive time by just a minute can increase harvest capacity by more than 1 acre per hour.

The efficiency gained by unloading on the go and reducing combine drive time to unload increases with longer rows, wider heads, faster combine ground speeds and higher yields.

Staton is a field crop educator with Michigan State University Extension.

Source: MSU Extension, which is solely responsible for the information provided and is wholly owned by the source. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like