February 13, 2020

With wetter-than-normal corn going into bins at harvest last fall, incidents of grain spoilage have increased during storage this winter. The grain surface at the top of some bins looks more like the dark side of the moon, with mold growth and grain turning black.

“A lot of wet corn went into aerated storage bins without being able to dry it to safe moisture content, and now we’re running into problems,” notes Charlie Hurburgh, Iowa State University Extension grain management specialist and director of the Iowa Grain Quality Initiative. “With the late planted 2019 crop, maturity was delayed. Spot shortages of LP-gas for grain drying last fall are another factor why grain entered bins at higher moisture content than normal. With the late harvest many farmers had to get corn out of the field because it was falling down.”

Farmers ran fans with unheated natural air on wet corn and got it cold soon after it was in the bin, with last fall’s cold dewpoints. This was OK in the short run. “But during periods of warmer weather, particularly when the sun is shining, the grain peak at the top of the bin and along the sides of the bin, gets warm from the sun,” he says. “If you have 20% to 24% moisture content corn in there and it gets warm, it doesn’t take too long before the grain begins to spoil.” The key is to refresh the cold temperatures of stored grain often, by running fans in times of low dewpoint.

Check grain temperature

What should you do with that corn now? “If it has already started to become moldy, you should remove the corn from the bin,” Hurburgh says. “It’s not going to get any better, and if it’s moldy, air from an aeration fan probably won’t go through it very well to cool it down. If the grain hasn’t become moldy yet, the key to remember is if you have wet corn stored at a temperature below freezing, below 32 degrees F, you need to refresh the grain temperature periodically. Maybe every week, particularly now as we start to get more sunny days and a little warmer weather. You need to refresh the grain temperature by running aeration fans to make sure the grain stays cold.”

Maintaining grain temperatures below 30 degrees is the best defense against spoilage for grain that’s wetter than ideal, Hurburgh says. This is colder than you would need to have for dry corn.

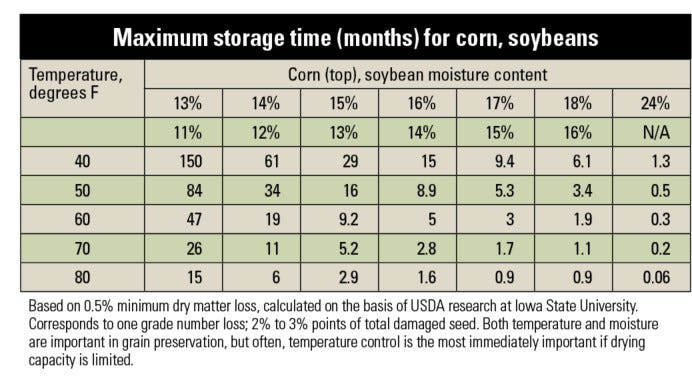

For grain to be safely stored through the winter, it’s recommended corn be 15% or below in moisture content, and soybeans 13% or below. To maintain that recommended stored grain temperature during winter, you should run the aeration fan when the outside air temperature averages (between the daily high and daily low) are near 30 to 35 degrees, which is warmer than is required to hold wet corn.

What does Hurburgh recommend as a test to get an idea of the condition of stored grain? Turn on the fan and smell the first air that emerges from the grain. Should you also pull some core samples from the stored grain and check it that way, to get an idea of what’s happening in the middle of the bin?

“Yes, pulling samples is a good precaution,” he says. “Most bins on farms now are so big you can’t really tell for sure by using only the sniff test. You can’t just go up in the peak and necessarily get an understanding of what the extent of the problem is or if trouble is occurring deeper within the grain mass.”

The best bin setups are those that have electronic temperature cables with remote readers, similar to those normally at elevators. But not all farm bins were built with them. The larger the bin, the more valuable the temperature system will be, Hurburgh notes.

Remove middle core

You should have removed the center core of grain from the bins already. That should have been done shortly after bins were filled last fall. If you suspect problems with stored grain now, take some more grain out of the middle to get a cross-section look at its condition. This will also remove most of the particles — the fines and trash that end up in grain in the middle of a bin and tend to make wet grain and quality deterioration worse.

“If you think there’s an issue with spoilage occurring in storage, take some grain out of the middle,” Hurburgh advises. “If it shows moldy corn and problems like some of the internet pictures and photos being sent around by people this winter, an extreme situation, then get that corn out of the bin. But use caution; moldy corn tends to hang up in augers. Don’t go into bins to try to dislodge moldy corn. That’s an unsafe practice, and we’ve had people having to be rescued from bins in these cases.”

Most of the spoilage problems in bins are with corn. Are there also problems with stored soybeans? “Some, but much less than corn,” Hurburgh says. “We didn’t have the wettest beans at harvest last fall. Last fall’s harvest was a little wetter than average for soybean moisture content, but still pretty much OK,” he says.

Problems require action

With stored grain problems, “You have to get on it and take action,” Hurburgh says. “It won’t get any better just leaving the grain in the bin.” The only real fix for out-of-condition stored grain is to unload the bin down to where the affected grain can be removed. This likely means grain will have to be marketed earlier than you had planned. And if it’s poor quality, it will receive a dock at the elevator. For feed use, cattle are more tolerant to damaged corn, so this may be a good on-farm option. Or if the grain is too out of condition to sell or feed, it will need to be spread back in the field.

Warning: Don’t try feeding moldy grain to monogastric livestock (swine or poultry). And it’s not wise to mix slightly moldy corn with good corn for feed, unless a veterinarian can advise accordingly, Hurburgh says.

“Another thing that’s probably going to happen with all this wet corn in storage, even if you keep it from getting visibly moldy this winter, is this spring and summer we will have higher incidences of grain spoilage and blue-eye mold,” he adds. “I don’t see how we can avoid it. The storage life of the corn is probably going to be used up. And 2019 corn, because it wasn’t fully mature, is likely to have shorter storage life to begin with.”

Take care of stored grain, Hurburgh advises. Even if grain went into the bin in good condition, monitoring it regularly pays dividends. Generally, check your stored grain at least every two weeks. If grain is wet or was damaged by frost last fall before you put it in the bin, you should check it weekly. To check stored grain, turn on the aeration fan and smell the first air that comes out. Also, use a thermometer to check the temperature of the air exiting the grain.

New technology for measuring carbon dioxide, a product of mold deterioration, is becoming more available. If carbon dioxide levels in the air exiting the bin rise to more than double the levels in the outside air, that means there is significant mold activity somewhere in the bin.

Managing grain this spring

If grain is over 18% moisture or so, or if it was damaged by frost last fall before you put it in the bin, you need to use it or sell it as soon as possible before the weather warms this spring, Hurburgh says. Or dry it down to safer moisture levels, according to the maximum time you plan to store it.

If your grain is in good condition at end of winter and you plan to store it longer — through spring or into summer — make sure corn is 14% moisture content or drier, and soybeans 12% or drier. Also, aeration to maintain proper grain temperature continues to be important, just as it was during winter storage.

You should maintain the grain temperature within 10 to 15 degrees of the outside air temperature to avoid grain quality deterioration caused by condensation developing on the interior of the grain bin. If you have good roof fans to circulate air from the outside in the peak, then you can keep grain colder longer because the roof fans will carry away condensation without warming the grain.

The best way to estimate what temperature the air will cool the grain to is to look at the dewpoint. In low humidity conditions, the dewpoint can be much lower than the outside air temperature. It’s important to monitor the grain temperature because low humidity air will also evaporate water and cause overdrying.

“Try to keep your stored grain as cool as you can,” Hurburgh says. “Checking grain temperature on a regular schedule and cooling the grain with an aeration cycle when needed is important. Grain management equipment such as roof fans and temperature measurement cables will pay rewards in keeping grain cooler longer, without overdrying.”

For information on managing stored grain as weather warms this spring, visit ISU Extension.

About the Author(s)

You May Also Like