Your grain bin held up fine last fall, so it’s ready to fill again, right? Gary Woodruff, district sales manager and grain conditioning expert for GSI, believes there is a better approach than knocking on wood … or metal.

“Inspect all parts of each bin, including the foundation, and if you’re not sure if it’s still sound, bring in your grain equipment dealer to help determine the best way to keep each bin safe,” Woodruff says.

In this interview, Woodruff shares specific tips for ensuring your bins are still usable and maintaining dryers until next fall:

What structural things should farmers look for in older bins to see if they are still sound? Though it doesn’t happen often, bolts can vibrate loose or may have not been replaced after a repair or addition to the bin. You can look for holes from the outside, but the easiest way to identify them is from inside an empty, dark bin in the daylight. They will stand out brightly.

Always check for serious rusting or other deterioration of the ring sheets themselves, particularly at the bottom of the bottom ring. Tapping those areas with a hammer may show them to be deteriorated further than a visual inspection would indicate. Damaged bin sheets can be purchased and replaced on most bins.

Check foundation bolts to make sure they’re still secure. Poured-in-place and epoxy fasteners are best, and any mechanical wedge-type fastener will eventually loosen up. Pulling on the fastener and hitting with a hammer will usually show if fasteners are loose. If so, a minor windstorm could pick up and damage the bin.

Once a bin is in overall bad shape or past 50 years old, it may be time to replace it and/or the concrete foundation. Badly cracked or damaged concrete can lead to structural failure, too.

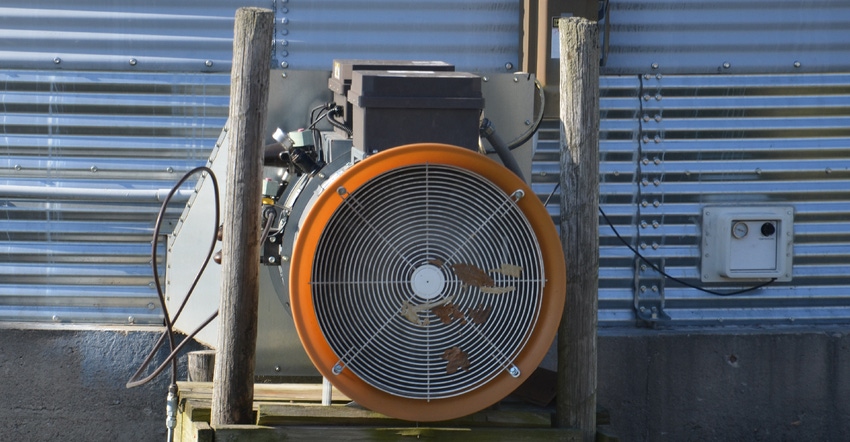

What type of oiling, lubrication or maintenance should be done on a continuous-flow dryer? Grease all grease points, check and change any gearbox oil, and oil all chains and other points requiring oil. General lubrication oil works in many places if not otherwise specified for most dryers. However, generally, gearboxes today require synthetic oil as specified in the manufacturer’s manual. Do not ignore the manual directions to change the gearbox oil. Every year is best, but letting it go more than four or five years will likely end up with a potentially expensive repair.

With in-bin dryers fueled by propane or natural gas, are there things that should be done now? Cleaning the burner is best done as the dryer is shut down for the year. This will be the area around the burner. On some burners, it means cleaning inside, possibly requiring some disassembly.

One often overlooked procedure is to shut off the gas supply to the dryer and then light the burner to purge the gas train of all pressure. Leaving pressure on gas valves can reduce their dependable life.

Most gas associations suggest replacing all flexible gas hoses periodically. This is usually listed as every 10 years.

About the Author(s)

You May Also Like