Brian Ward hopes that organic ammonium fertilizer created from a process he patented will be readily available to vegetable producers and other farmers across the country.

In January, the U.S. Patent Office granted Ward, an organic vegetable specialist at Clemson University’s Coastal Research and Education Center in Charleston, S.C., a patent for a bioreactor that distills ammonium fertilizer from hyper-ammonia producing, or HAP, bacteria that comes from the stomach of cattle.

Ward’s patented process creates the first-ever organic ammonium fertilizer, and the Clemson scientist sees tremendous market potential for the fertilizer. Ward’s patented process meets the strict standards to receive organic certification. Ward is now seeking a major company to license his bioreactor and manufacture, market and distribute the organic fertilizer

“There is basically no difference between my fertilizer and synthetic fertilizer. It’s primarily the same product. It provides the same nutrients. Plants can’t tell the difference,” Ward says.

Organic fertilizers effectiveness depends on how active bacteria are in the soil. Ward’s process overcomes that obstacle through the use of what he calls “extreme bacteria” to effectively activate the nitrogen in the soil.

The HAP bacteria break down proteins that bind nitrogen to ammonia significantly faster than any other known bacteria, which allows ammonium nitrate to be produced in vast amounts at an accelerated rate.

“Ultimately, if we start to get the fertilizer commercialized, producers would be able to fertilize organic crops and have the yield comparable to conventional produce without the lag time of existing organic produce,” Ward said.

An added bonus of the process is that it does not require the use of fossil fuels to manufacture.

“Two percent of the world’s energy is devoted to making ammonium fertilizer,” Ward said. “This does it organically, so there would be a huge cost savings.”

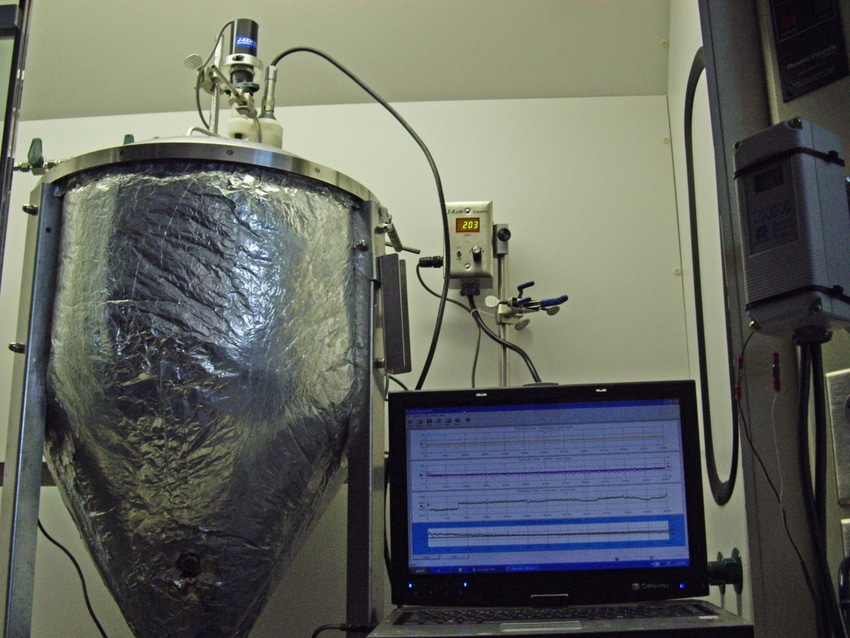

Ward engineered a bioreactor in his lab at the Coastal REC and used it to create a reaction that releases four products: ammonium, butyrate, acetate and nearly pure carbon, similar to coal.

He was able to use the ammonium released to produce a liquid fertilizer that could be fed through drip lines as a precision organic fertilizer.

With the patent in hand, Ward is now seeking a major company to license the reactor and manufacture, market and distribute the new organic ammonium fertilizer. He hopes the product will be available in a small scale in a year and marketed on a large scale by 2021.

About the Author(s)

You May Also Like