August 11, 2017

The 2017 LIFT2 (Leaders of In-furrow & Foliar Technologies, http://inthefurrow.com) field day at the CHS Dakota Plains research plot near Leonard, No. Dak., showcased recent developments and challenges regarding new technologies in agriculture. It was hosted by West Central Distribution, along with partners BASF, Dow AgroSciences, FMC, Nufarm and The Climate Corporation.

Here are the highlights…

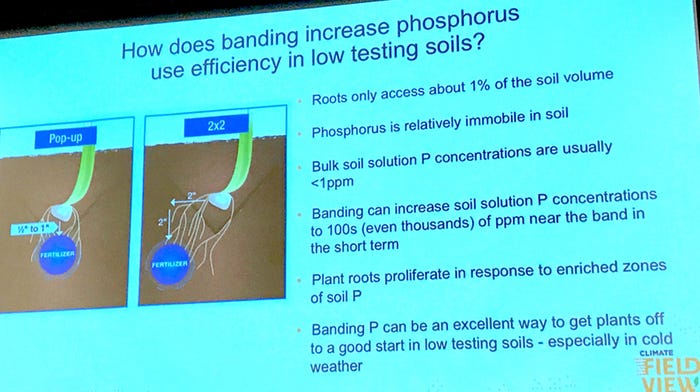

Brad Joern, longtime Purdue agronomist, now with Climate Corp., discussed his years of research on phosphorus (P) and his role to help Climate Corp build customizable prescription fertilizer recommendations.

As the slide shows, roots only explore about 1% of the soil volume, Joern says. That’s why banding works well, as roots like enriched zones of phosphorus to get plants off to a good start especially in cold soils.

“The problem with P is that its use-efficiency is really really low. And a lot of soils out there test below the critical P level. Low organic matter soils won’t release much essentialphosphorus to plants, so banding phosphorus can be very beneficial in these cases,” Joern says.

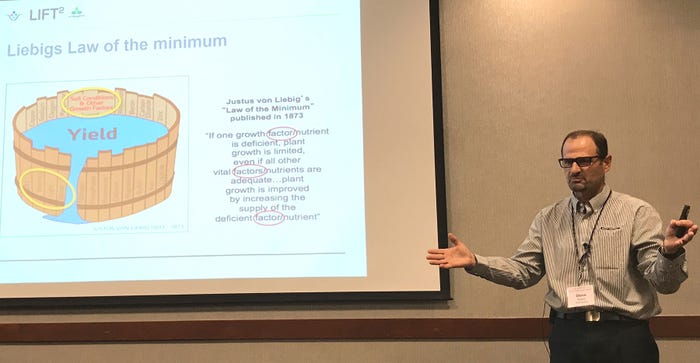

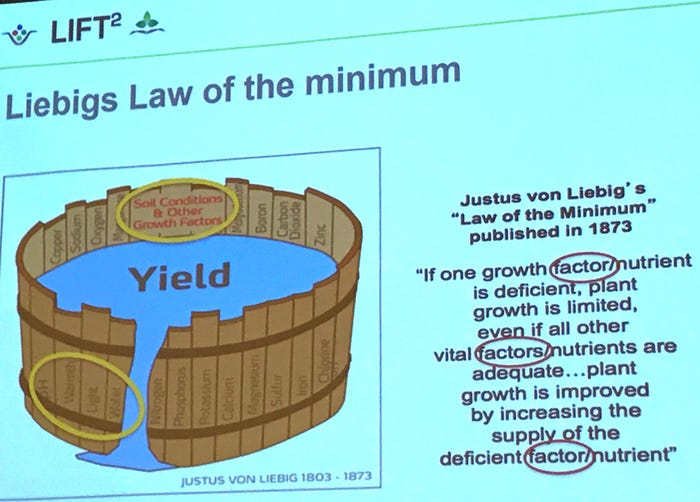

Steve Roehl, research analyst/agronomist with West Central discussed how the maximum yield of a crop is limited to the most limiting essential nutrient.

Roehl however, goes on to explain that we need to rethink our nutrient philosophy away from merely fertilizing to high or very high soil test fertility levels. Yield limitations relating to crop nutrition also involve soil conditions and other growth factors that limit the uptake of the 16-18 essential nutrients: like concentration, ionic form and amount available.

He quotes University of Illinois agronomist Fred Below who has identified input factors that most drastically impact yield. And there are prerequisites, like the need to make sure we have good soil drainage, good weed and pest control, and make sure that the plants never have a stressful day from a crop nutrition perspective. He reminds growers to check out these factors in Below’s work:

· Seven wonders of the corn yield world http://inthefurrow.com/seven-wonders-corn-yield-world/

· Six secrets of soybean success http://www.cornandsoybeandigest.com/soybeans/6-secrets-soybean-success

Roehl adds that since plants must drink their food, keeping nutrients soluble is a challenge given their individual positive/negative charges and how their ionic form influences solubility with water. Phosphorus has an overwhelming tendency to get bound up with other nutrients and when it does the resulting bonds make them both insoluble and no longer able to be taken up by the plant. P is such a negative molecule that it likes to only bind with almost all positively charged molecules.

Given that, and the dramatic changes to agriculture including vastly increased yield potential of new technologies and germplasm, our soil sample program is having a hard time catching up to deliver accurate available P data, Roehl says. We need more data to support our soil sample and fertility model.

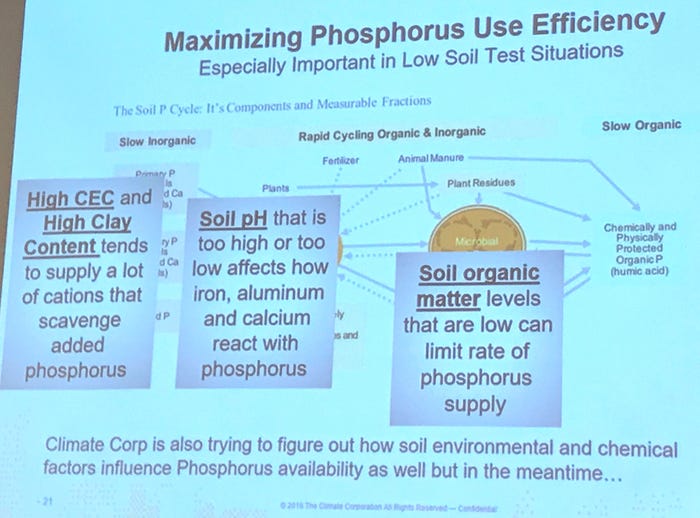

Roehl shows this slide to outline the complexity of the phosphorus model in the soil – there’s a lot going on. “When you look at soil properties like CEC and clay content, soil pH and soil OM, each can have a drastic effect on overall phosphorus availability. Climate Corp is looking at modeling these factors, as well as trying to figure out how soil environment and chemical factors influence phosphorus availability,” he says.

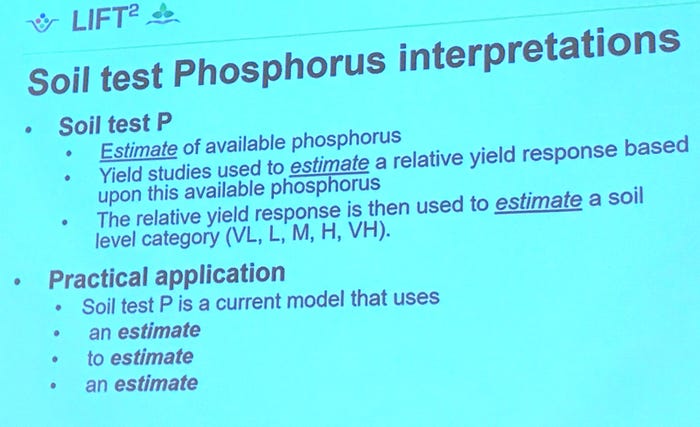

There are a lot of challenges with estimating Phosphorus. In soil test P, labs use an extract to estimate available P. Then they use yield studies to estimate a yield response. That yield response is then used to estimate a soil level category. “So this Soil test P model uses an estimate to estimate an estimate. So, although our current soil analysis and recommendation strategy is still a working model, we probably have some room for improvement here,” Roehl says.

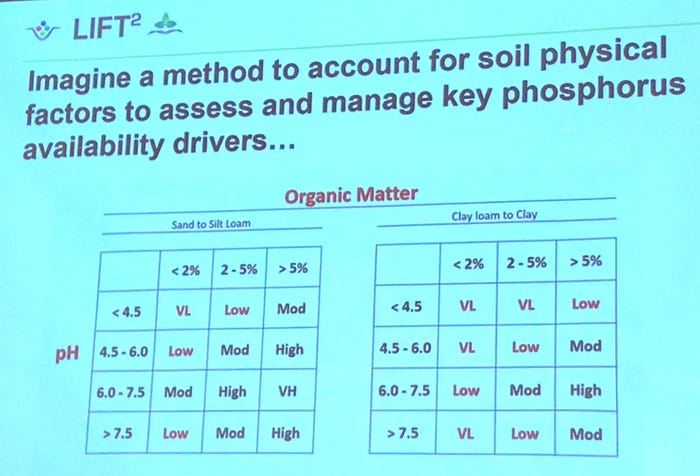

“So if we start to account for soil physical factors (like OM and pH shown here), we can begin to assess and manage key phosphorus availability drivers. Shown here are two matrices of soil physical factors, one with low and the other with high clay textures, each representing low to high organic matter percentages and pH ranges – these matrices provide a more accurate level of available phosphorus, to help adjust recommendations with the current soil test model,” he says.

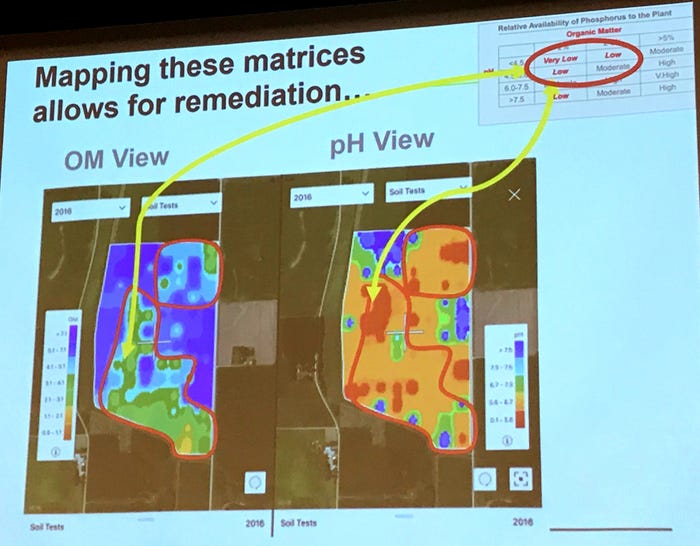

Roehl says with this data knowledge, we can build a prescription map to improve phosphorus availability where it is needed. “This is where starter fertilizer strategies can be utilized to give plants a concentrated band of nutrients where roots can easily find it without searching. And the use of starter fertilizers allows for use of prescription nutrient enhancement products, like the Levesol line,” he says. http://www.westcentralinc.com/products/

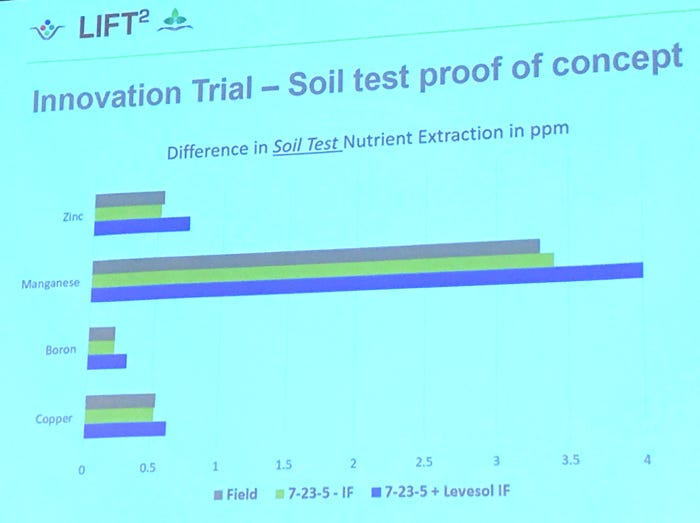

In this soil test nutrient extraction research (zinc, manganese, boron and copper shown here), the gray bar represents the field average in between the rows, not in the starter band. The green bar represents a phosphorus-based 7-23-5 starter band in the furrow. The blue bar represents where we added Levesol to the starter. In all cases, you see an uptick in nutrient availability when Levesol is added.

Levesol from West Central is claimed to be the only patent-pending combination of pure chelating agent and nitrogen fertilizer possessing soil activity that can be mixed with liquid fertilizer and applied in-furrow. But, it is the ortho-ortho EDDHA chelate that differentiates the product and makes micronutrients soluble for uptake, with increased translocation within the plant. This prevents binding with phosphorous to allow for greater uptake and increased overall nutrient efficiency.

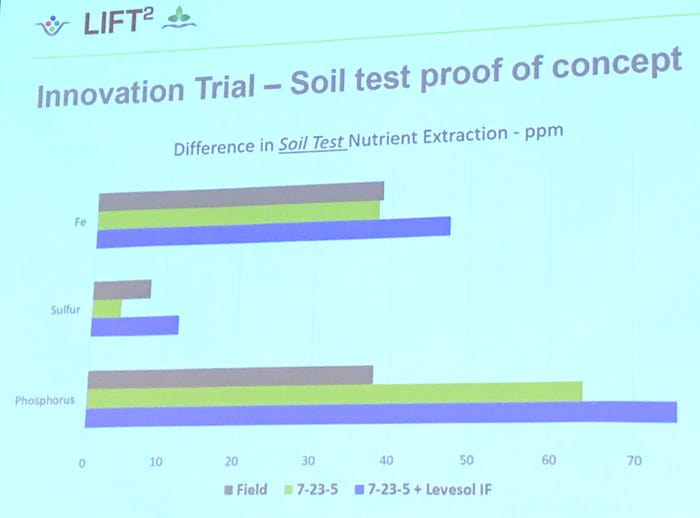

From the same nutrient extraction test (iron, sulfur and phosphorus shown here), you can also see a good increase in phosphorus availability from the phosphorus based fertilizer alone, which makes sense since the fertilizer contains phosphorus but this availability can relate to an even greater increase with Levesol added.

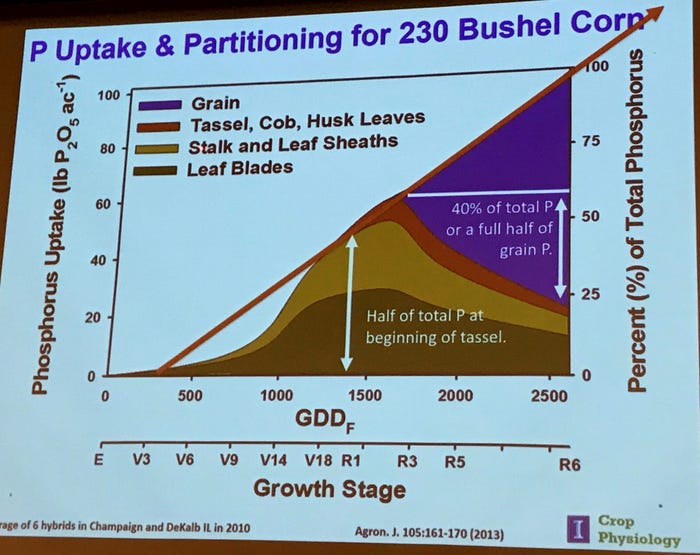

More data from Fred Below showing nutrient uptake by modern corn hybrids. Phosphorus is needed early in the season, with half taken up before tassel. Following that, phosphorus needed for grain fill is taken from the tassel, stalk and leaves to feed an enormous appetite by the corn grain. Roehl says that if we can increase the efficiency of phosphorus being resolubilized and moved from other parts of the plant to the grain, we have an opportunity to increase crop growth efficiency. Increased plant uptake can reduce the amount needed from other plant parts altogether, allowing better leaf and stalk integrity later into the season and better grain fill. Below’s work shows that nearly 80% of all phosphorus taken up by the plant must end up in the grain. So he believes increased P uptake can and will increase yield.

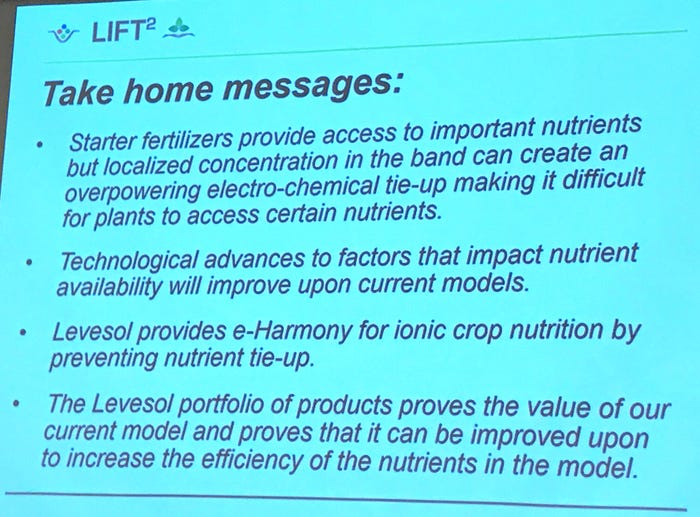

Roehl concludes by emphasizing that starter fertilizer needs help to ensure plants gain access to all nutrients in a concentrated band, and that technological advances can improve current soil test models. Levesol family of products is a technology that helps increase the efficiency of crop nutrient uptake.

The next major presentation dealt with the challenge of reducing spray drift. Tom Butts, Graduate Research Assistant with the University of Nebraska’s Pesticide Application Technology Lab, presented the four main factors that influence drift:

1. Wind speed and wind direction has the largest impacts on drift. When wind speed doubles, there’s a 700% increase in drift deposition 90 feet downwind. And as boom height increases, wind speed increases. Take accurate wind speed measurements at boom height. Butts recommends using a wind flow meter that attaches to a mobile phone to record and document all measurements for your spray log. One example of such a wind meter: http://weatherflow.com/wind-meter/

.

2. Boom height is very crucial, and set based on nozzle type used for proper coverage. When boom height changes from 18 inches to 36 inches above target, you increase drift by 350% 90 feet downwind.

3. Safe distance from susceptible vegetation, bee hives, etc. In other words, buffer zones. They are going to be more abundant on labels as we go forward. Know your surroundings.

4. Spray particle size. It impacts drift a ton, and is one aspect we can control. We use lasers to measure droplet sizes in our wind tunnels. We measure the balancing act of efficacy versus drift concerns, with the goal to reduce driftable fines (<150 microns in size). How can we reduce this? Slowing down and reducing pressure reduces driftable fines. Adjuvants won’t deliver as big of a change in droplet size as a nozzle can, but can fine-tune an application for optimization. Increasing nozzle orifice size can reduce fines and help us get our speed back. Different nozzle types can reduce driftable fines. For example, the TTI spray tip http://www.teejet.com/xtend/index.shtml is becoming more popular for use with dicamba herbicides because they generate less than 2% driftable fines. But Butts says they currently must test all different mixtures because every adjuvant and active ingredient changes droplet size.

Check out this droplet size calculator: http://pat.unl.edu/droplet-size-calculator

Butts also discussed the importance of following the exact label recommendations for all uses of dicamba and 2,4-D on traited crops, referring to these websites to keep up on the rapidly evolving recommendations:

Dow AgroSciences: http://www.enlist.com/en

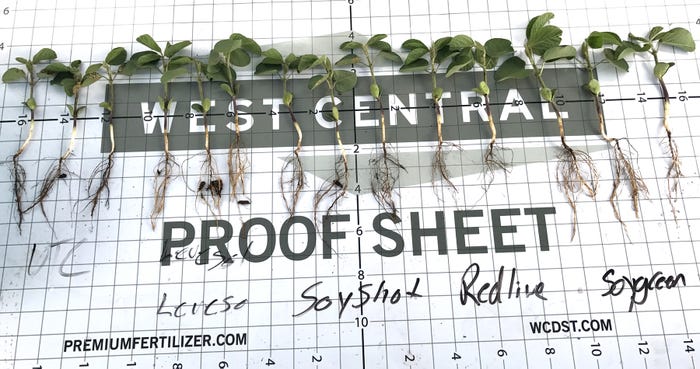

- These plants were pulled from the soybean field plot we visited. Steve Carlsen, West Central Distribution, described the visual differences with various Levesol family products on young soybeans from the field plot. From left to right: First the untreated check (UTC). Next to it is the addition of Levesol alone at 64 oz./acre in 7 gal water. Next is Soyshot, a 0-10-10 starter fertilizer with the chelate built-in. Redline, used more often on corn and sugar beets, is a 6-12-2 starter with zinc, iron, manganese and copper. And last is Soygreen, an iron formulation that keeps iron soluable for plant uptake to combat iron deficiency chlorosis (IDC). It is applied either in-furrow or as a postemergence foliar spray.

Also during the event, we had a chance to catch up with the other sponsor companies, who offered these highlights:

FMC

Rick Ekins with FMC discussed the continued success with the 3rive in-furrow system, working with new applicators and farmers over thousands more acres in 2017.

“A new successful pilot program this spring gave farmers a free 3rive system in exchange for a signed agreement to buy Capture 3RIVE 3D insecticide,” he says. “MicroTrak has done a fantastic job with the technology, the system is workingly nicely, and now we’re looking at building the product portfolio formulated to work with the 3rive system.” (http://www.fmccrop.com/grower/Products/In-Furrow/3RIVE-3D-Equipment.aspx)

FMC is currently field testing an insecticide/fungicide combination (3rive version of Ethos+Capture), testing a straight fungicide, and testing a highly systemic triazole fungicide for SDS in soybeans that lasts longer than a seed treatment, Ekins says.

Micro-Trak released an ISOBUS solution for the 3rive system that gives farmers added accuracy (https://www.micro-trak.com/3rive-3d) . “Not only can farmers apply variable rates, they can apply at sub-ounce rates since the air system helps the foam to cover the entire seed furrow zone,” says Jake Dahle with Micro-Trak Systems.

“The exciting thing about the future of this technology, unlike seed treatments, is that there are no limits to the chemistries we could apply with foam in the furrow – without concern for dust-off or seed coating overload. And we could variable-rate the headlands different than the middle of the field, or zone by zone changes,” adds Ekins. “The possibilities are exciting, and we’re looking at other crops besides corn and soybeans, like sugar beets and more.”

Dow AgroSciences

Jake Wiltrout with Dow AgroSciences touted the increasing use of nitrogen stabilizer Instinct HL (http://www.dowagro.com/en-us/usag/product-solution-finder/nitrogenstabilizers/instincthl) being one of the best investments per acre that farmers can make to help protect N in the root zone. This formulation replaces Instinct II, featuring a lower use rate (24 oz./acre) but the same amount of stabilizing material in the product. There are no more sticking issues with this formulation on dry fertilizer/urea, and the average yield increase in corn is 7 bushels per acre in this area, he said. Goal is to protect fall-applied urea, or even protect 28% N or manure applied in the spring.

Nufarm

Tom Kroll with Nufarm (http://www.nufarm.com/US/Home) works with West Central to provide them with product for their STI customized program (http://www.westcentralinc.com/blog/seed-treatment-custom-blends-create-happy-customers/). “They take our technology and other company technology to formulate the best seed treatment package, customized on a regional basis,” Kroll said. Quality formulations are key when blending numerous chemistries, so we work closely with West Central to achieve high performance treatments. And we’re a big believer in using polymers whenever insecticides are incorporated into treatments to eliminate issues of dust-off that can impact pollinators, he added.

BASF

Scott Stout with BASF discussed the importance of fungicides on plant health, and the value of products like Headline Amp (http://www.agproducts.basf.us/products/headline-amp-fungicide.html) that delivers ROI 76% of time it is applied. “We hope that we can increase that ROI success to 90% as we gain more data to help growers apply it to the right hybrids and right fields. Growers are learning that this fungicide is beneficial as an insurance piece over the long term. They don’t need to see disease to get ROI,” he said

Stout also hightlighted Manticor LFR (http://agproducts.basf.us/products/manticor-lfr-in-furrow-fungicide-and-insecticide.html), a new formulation rate of Headline and Capture LFR launched this year as an in-furrow combination specifically targeted for corn rootworm control along with seedling diseases. “The bifenthrin (Capture) component in-furrow offers another mode of action against corn rootworm to help increase protection of traited hybrids to deliver better stands and quicker emergence in tough conditions. And the Headline fungicide component will give growers an extra 14-15 days seedling disease protection beyond seed treatments, extending to the V1 corn stage,” he said.

About the Author(s)

You May Also Like