July 10, 2020

Poor pen conditions due to early snowfall and rainy weather last fall plagued cattle feeders in much of North Dakota.

Muddy conditions have been shown to decrease intake, gain and feed efficiency, which results in increased cost of gain. While the use of bedding is a well-accepted way to mitigate these affects, the need to clean pens and rebuild and pack pen surfaces to re-establish proper drainage is necessary for optimizing long-term efficiency.

The majority of feedlot pens are soil based, with mounds created to provide dry areas for bedding. However, in recent years, more feedlot operations in the Northern Plains have been looking at alternative pen surface materials to decrease the annual expenses associated with hauling fill (clay or gravel) back into pens to maintain grade and allow for proper drainage.

Hard surfaces including fly ash, concrete, and a newer product known as roller compacted concrete, which is being used in a number of feedlots in western Canada, allow for longer lasting pen surface conditions. These hard surfaces also come with an increased cost.

Beyond advantages to pen surface maintenance and depending on wastewater holding capacity and permitting regulations in your given state, utilization of solid surfaces, including concrete, may allow for greater stocking density of feedlot pens.

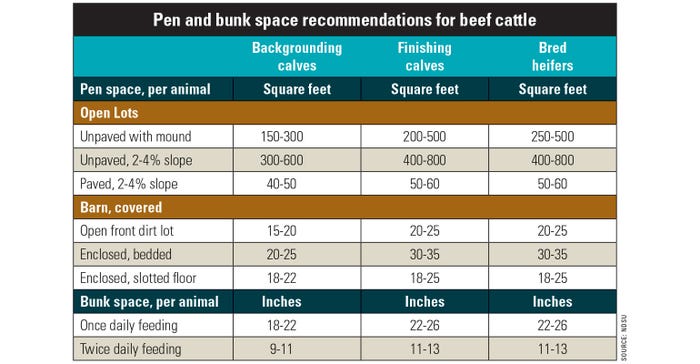

As an example, by moving from an unpaved open lot (2% to 4% slope) to a paved surface with the same slope, stocking rate increases dramatically as space requirements decrease from 600 square feet per animal to 55 square feet per animal for feedlot cattle. Producers should also consider other management practices, as well as bunk space, as part of their decision process.

Like many operations, the North Dakota State University Carrington Research Education Center’s livestock unit is struggling with the recurring costs associated with feedlot pen maintenance. Fly ash was placed in the pens in the late 1990s, but this material has deteriorated over time. The center has moved forward with the process of concreting a portion of its feedlot pens. This will provide advantages in the long-term growth of the center’s research program.

To see the new renovations, call 701-652-2951 or stop at the center’s main office.

Neville is a NDSU animal scientist at the Carrington Research Extension Center.

You May Also Like