It’s never too early to get your machines ready for harvest, and that’s even more important when it comes to chopping corn silage.

You’re going to have a short window to harvest the best-quality crop, so having a clean, ready machine is critical to avoid early problems.

“You have to be ready when the moisture content of the corn, what your after to make sure it’s the most nutritious, is in the best shape it can be for the livestock,” says James Franceshetti, product marketing manager for New Holland Agriculture. “And it all goes back to the proper maintenance, being ready to make sure that you’re able to harvest that corn silage or make corn silage as efficiently as possible. You just want to make sure that, top to bottom, front to back, whether it’s a pull-type forage harvester, self-propelled forage harvester, that you’re ready to go when that crop is ready.”

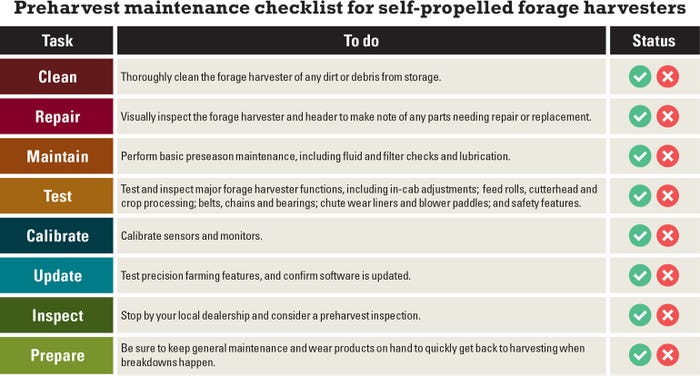

Whether you have a self-propelled forage harvester or a pull-type machine, the preharvest maintenance checklist is similar, but there are differences.

First, though, make sure the machine is clean.

“Remove debris that resulted from storage,” Franceshetti says. “Or maybe you didn’t do a good job cleaning it. Make sure you start cleaning it as soon as possible.”

From there, Franceschetti says it’s all about checking and maintaining the parts that meet the crop.

“So that means the cutterheads, the knives on that, the shear bars, all that is super important to make sure nothing is dull or damaged, or broken,” he says, “because this is where the majority of work is done.”

Same thing with a pull-type machine, Franceshetti says, but the crucial PTO is also important to check.

“Make sure the driveline and everything related to that is fine in connection to the tractor,” he says. “The yokes, U-joints, bearings and chains, make sure to check all that. Check your grease points, and make sure everything is lubricated correctly.”

Not to be overlooked

So what are the things Franceshetti says producers often overlook when they’re getting their chopper ready?

“The crop-engaging components are hugely important,” he says. “I think that it's often overlooked because it's such a common part of the machine that, you know, you kind of just think that it'll work as intended, but they're easy enough to replace, too, these shear bars and knives. So just make sure you have something that is sharpened and not worn, and that it is properly faced, that you're cutting the corn crop at the correct length so that it can be sent through the processor as the machine is intended to do.”

And don’t forget the in-cab technology, especially in your self-propelled machine.

"Some producers might forget that there are a lot of settings and precision that can be done in the cab,” Franceshetti says. “So maybe making sure to clear that information out to make sure your GPS and your yield monitors are set up for the current season, and not necessarily relying on any settings that you made last year because field conditions change; we all know crop conditions change.”

Don’t forget safety

Safety starts in the shop when you’re working on the machine, making sure you have the right personal protective equipment on hand, making sure the machine is on level ground and that you’re working with the right tools.

Out in the field, Franceshetti says to ensure the metal detection system and rock traps are working properly.

“Just make sure you’re doing everything to stop foreign material from getting into the processor,” he says. “And just keep it clean. So make sure you clean debris daily, greasing and lubricating.”

Getting parts

Franceshetti says most common parts producers need should be available come harvest, but ordering parts earlier is always best.

"We've done a really good job, in spite of all the challenges that we've seen, to make sure our dealers are stocked and ready to service their customers," he says. “How soon should a producer get their maintenance done and get their parts ordered? I always say the sooner the better. I don't think you could ever overprepare for your upcoming harvest. If you're starting to get worried that maybe you didn't look at that piece of equipment, maybe you haven't done that preharvest inspection, you haven't cleaned it, you haven't taken it out of the barn, it's probably a little too late.”

About the Author(s)

You May Also Like