Grain aeration controllers debuted in the late 1980s. But those controllers, especially the early models, still required the grower to set controls and interact with the system.

GSI now offers a flexible system that can do as much or as little grain management as you want. If you prefer, GrainVue can monitor and manage grain from drying in the fall until you’re ready to sell it.

“We should emphasize upfront that you still must monitor grain yourself,” says Greg Trame, director of technology sales for GSI. “Nothing is foolproof. It wouldn’t be wise to fill the bin and walk away until the day you’re ready to haul grain out. You should still monitor these bins routinely.”

The difference is that GrainVue monitors and manages grain to precise moisture levels, based on the moisture target you select, without you deciding to turn fans on and off.

How GrainVue works

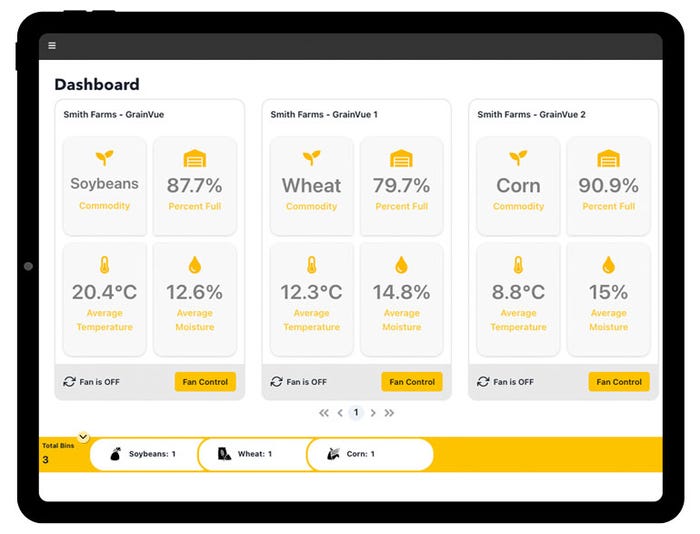

The GrainVue system uses cloud-based connectivity that makes remote management possible, Trame explains. A hub on top of each bin equipped with GrainVue transmits information from monitoring cables inside the bin to the cloud, which sends that information to a GSI control center.

Two types of monitoring cables are available: temperature cables and moisture cables, which are more expensive but also monitor temperature. Sensors are spaced 4 feet apart on cables, mounted vertically inside bins.

Based on information received, software uses algorithms to determine recommendations for managing fans and relays directions back to that specific bin.

“The interface that shows what’s happening is easy to use,” Trame says. “The grower can override it and control it manually. Since it’s a cloud-based system, he doesn’t have to be at the bin. He can view it and make changes from anywhere.”

What economics say

A fully automatic system for a typical 48-foot-diameter bin holding 50,000 bushels or more would cost around $10,000 for all necessary equipment, not counting installation costs, Trame says, explaining, “Installation costs vary widely depending on existing electrical service.”

Plus, there is a fee of $200 per bin per year that covers cellular service. “That’s the only other cost involved,” Trame says.

If you’re not ready to invest in the fully automatic system, you can install only temperature or moisture cables to reduce costs. You get accurate information, and then make decisions yourself.

“Cost varies depending on how many moisture cables you install,” Trame says. “You need at least one moisture cable per bin if you want to use Smart Dry and Smart Storage, the fully automated options.”

How much would it cost per bushel for fully automated control from harvest though storage? Here’s an example: For a 50,000-bushel bin, if equipment costs are $10,000, installation costs are $5,000 and the annual fee is $200, then the per-bushel initial investment is about 30 cents. Recurring annual direct cost for the cellular service fee would be under half a cent per bushel.

About the Author(s)

You May Also Like