February 25, 2022

Seed Size and Shape

Varying environmental conditions may result in a variety of seed sizes and shapes from the same corn product. Seed size is also affected by corn product genetics and growing conditions, especially during the pollination and grain fill period. Typically, large rounds come from the base of the ear, flats from the center, and small flats and small rounds from the tip (Figure 1). Plateless seed usually comes from the base or the tip. All seeds from the same ear, regardless of size or shape, have the same genetic material, and thus the same genetic yield potential.

Figure 1. Seed size and shape on a corn ear varies from large rounds (cob base), flats (middle of cob), to small rounds (cob tip).

While genetic yield potential is not affected by seed size, there can be differences in germination related to seed size when conditions are not ideal. Large seed may not germinate as well in dry soil conditions because large seed requires more moisture to germinate compared to small seed. Small seed may not germinate as well in cool or crusted soils because the energy needed for emergence may be greater than the amount stored in the seed. After tasseling, differences in germination related to seed size are usually no longer apparent. Regardless of seed size and shape, similar silking dates and yield potential are expected when established stands are the same.

Seed Weight

Seed weight is becoming the more common way in which farmers purchase their seed, which is often based on how their planter is configured. More seed companies today are selling their seed based on the weight of the seed and not as much on the size of the seed. As noted above, the size and weight of the seed does not affect yield potential. Yield potential is determined by genetics, product positioning, and management practices. When purchasing corn seed by weight, review the seed bag labels and your planter manufacturer's recommendations, and talk with your seed brand agronomist or representative for information on dealing with different types of seed, planter specifications, and field placement. When properly managed and properly positioned, corn seed of any size and weight can produce a successful crop.

Planter Adjustments for Seed Size and Shape

Planter settings should be adjusted for accurate seed positioning, placement, and seeding rate

When adjusted for seed size, a planter can more accurately singulate and deliver seed. Planters can deliver excessive numbers of doubles or skips when improperly adjusted for seed size. Consequently, grain yield potential can be reduced by 3 to 10 bushels per acre.1

Vacuum Planters

Adjustments can be made to the vacuum pressure, disk and/or cell size, and seed singulation devices that can affect plantability. Planters equipped with cell or flat disks have different requirements for adjustment. Another component to examine, regardless of disk type, is the way the disk is adjusted relative to the meter housing. Having the disk rub the housing with light contact can help improve singulation, reduce seed damage, and help load the planter drives, improving their consistency.

Using talc, graphite, or a blend of the two can help improve seed flow and drop, especially with high rates of seed treatments and/or humid conditions. Increased rates of talc or graphite may be necessary for the increased surface area with small seed. Talc or graphite should be mixed well throughout the hopper or tank to provide adequate coverage.

Vacuum Planters with Cell Disks

With cell disks, seed is partially held in place by the cell and partially by the vacuum pressure. Plantability is aided by matching different cell sizes and vacuum pressures to fit a given seed size and shape. Disks with cells that are on the larger side of the acceptable range for a given seed size could lead to doubles, even if the vacuum pressure is adjusted to the lower side of the acceptable range. Low vacuum pressures also increase the chance of seed being shaken off of the disk when planting over rough ground, resulting in increased skips. To help reduce doubles and skips, disks with cells on the smaller side of the acceptable range can be used while running vacuum pressures on the higher side of the acceptable range.

Vacuum Planters with Flat Disks

Flat disks are less sensitive to different seed sizes and shapes and can provide more consistent plantability while reducing the need to adjust vacuum pressure. Examples are the Precision Planting® eSet® and vSet® systems and the John Deere® ProMAX 40 Flat Disk. Use of flat disks usually requires an additional component or two for singulation. The eSet and vSet systems utilize a floating singulator that requires no adjustments for ease of use while the ProMAX 40 Flat Disk uses a double eliminator and a knock-out wheel. Flat seed disks may need a slightly different environment than cell disks and users may benefit by visiting their equipment dealer for inspection and testing of their seed meters.

Finger Pick-up Planters

To help minimize planting errors, the following items can be evaluated and adjusted to operator manual specifications:

Proper tension on the fingers

Condition of meter brushes and carrier plate

Pliability of seed delivery belt

Seed baffle cleanliness

Proper lubrication (graphite) rate

Good alignment with meter drive and the lugs on the unit drive sprocket

Well-maintained and lubricated drive chains

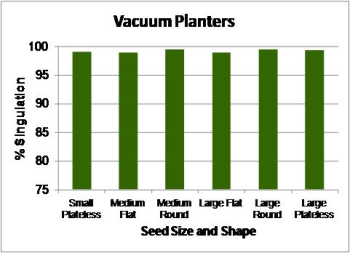

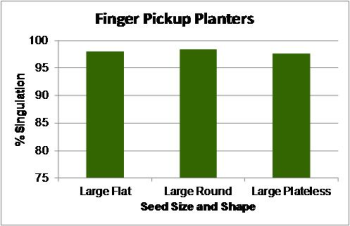

Plantability Studies

Plantability tests have been conducted to provide planter setting recommendations for seed lots. Results of the tests conducted are represented in terms of percent singulation or the percentage of single seeds released by the seed meter at the proper time. If the seed sensor detects two seeds where only one should be, then it is called a multiple. If the seed sensor detects nothing where a seed should be, then it is considered a skip. Therefore, percent singulation is determined by taking 100% properly timed single seed drops and subtracting the percent multiples and percent skips.

Figures 2 and 3 demonstrate singulation data for vacuum or finger pick-up planters and various seed sizes and shapes. The finger pick-up units were calibrated for larger seed and data for smaller seed sizes and shapes are not presented. Simulated planter speed was 5.5 miles per hour. Data was collected using seed harvested in 2004 through 2010 for planting seasons in 2005 through 2011, respectively.

Source: DeKalb, Asgrow and Deltapine, which is solely responsible for the information provided and is wholly owned by the source. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like