August 10, 2018

By Glennis McClure and Jim Jansen

As ag profit margins have dipped and the cost of harvesting equipment has escalated, comparing equipment ownership costs to custom hire rates may be in order. If available operators could harvest your acres in a timely manner, would using custom hire services for harvest be a good economic decision on your farm or ranch? Comparing current custom rates for your region to equipment ownership and operating costs using a partial budgeting worksheet can guide the decision-making process.

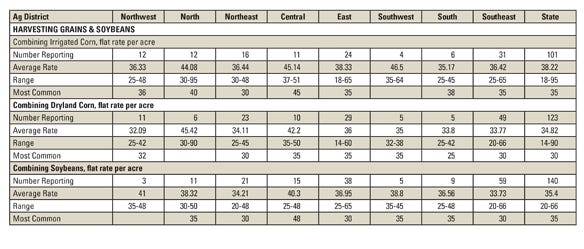

The University of Nebraska-Lincoln recently published survey findings on the average custom rates reported for fall harvesting across the eight Nebraska Agricultural Statistic Districts. Rates for combining irrigated corn, dryland corn and soybeans on a per acre basis from the 2018 Nebraska Custom Rates Survey Report are shown in Figure 1. The full report is available at go.unl.edu/custom-rates.

FIGURE 1: 2018 Nebraska custom rates for corn and soybean harvest. (Source: 2018 Nebraska Custom Rates Survey Report)

The custom rates for harvesting fall crops varies across Nebraska due in part to the variability of crop yields, type of ground, availability of custom operators and demand for custom services in some areas vs. others. In some cases, custom machine hires may be charged based on covering only operating costs and not necessarily all machinery ownership costs, or coverage of management and labor costs.

In owning the harvest equipment, including a combine, corn head and grain platform for soybeans and other crops, it is crucial to consider ownership costs, including depreciation, interest, taxes, insurance and housing for equipment. Annual operating costs including fuel and lubricants, repairs and maintenance, and labor needs to be added to ownership costs. Nebraska custom operators in 2018 noted that on average they factored in $18.85-per-hour labor costs and a $2.46-per-gallon diesel price according to custom rate survey responses.

A partial budget can be used to estimate the net income difference of owning a combine versus hiring a custom operator for harvest work. This tool guides the decision-making process by determining increases, decreases or unchanged effects in net income compared to the change in business.

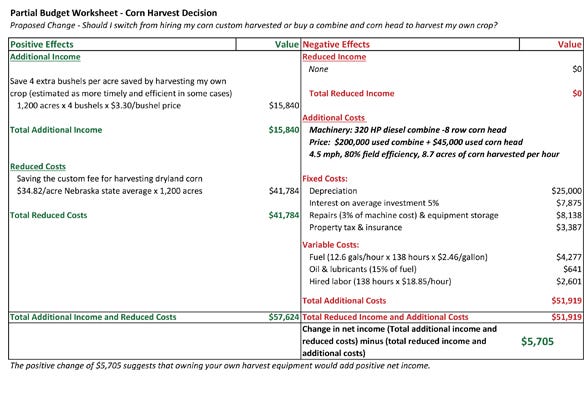

The left-hand side of the partial budget includes the positive effects on net income including additional income and reduced costs. The right side of the budget notes any negative effects of a proposed change, including reduced income and additional costs.

A simple partial budget example using the Nebraska custom dryland corn harvest rate of $34.82 per acre and costs of owning and operating harvest equipment for 1,200 acres is shown in Figure 2. For this example, cost of owning and operating equipment for corn harvest is illustrated. These figures do not include the ownership costs of an additional grain platform that would be needed for harvesting soybeans or other crops.

Figure 2 (Source: Jim Jansen and Glennis McClure)

The proposed change to consider would be if the net income is positive for a farm operation to switch from hiring corn custom harvested to buying a combine and corn head to harvest their own. This example uses the Nebraska custom dryland corn harvest state average price of $34.82 per acre. If custom harvest were not hired, 1,200 acres at the $34.82 per acre custom rate would be a reduced cost.

Additional income in the example factors in the assumption that the farmer might save an additional 4 bushels of corn per acre if harvesting his own crop given a timelier harvest. The negative effects or additional costs in the partial budgeting example take into account the fixed and variable costs of owning and operating a used 320-hp combine and a used eight-row corn head.

The results of this partial budget indicate a positive $5,705 in owning and utilizing the corn harvesting equipment versus custom hiring harvest done.

Would this be enough of a savings to cover the investment risk of owning and operating the machinery? In addition, if there was a crop mix and a grain platform must be purchased, that would add costs. If the farmer in this case was not saving 4 bushels per acre by harvesting his crop, this would reverse the scenario to indicate a $10,135 negative effect to owning and operating his own harvesting equipment.

Overall, there are many variables to consider when determining whether to hire field operations and harvesting done on a custom basis, or to own the equipment and do it yourself. The size of operation, your time, availability of good custom operators in your area, custom rates, equipment costs and harvest efficiency are all factors that contribute to making an economical decision.

McClure and Jansen are agricultural economists with Nebraska Extension.

You May Also Like