August 16, 2016

You may not own the stereotypical robot yet. But if you drive a tractor with autosteer, you are already using one, or at least parts of it. Whether it takes the form of end-of-row turn technology, self-adjusting combine shoes, or automated feed-rate control systems for balers, a robotized system requires three basic components to work.

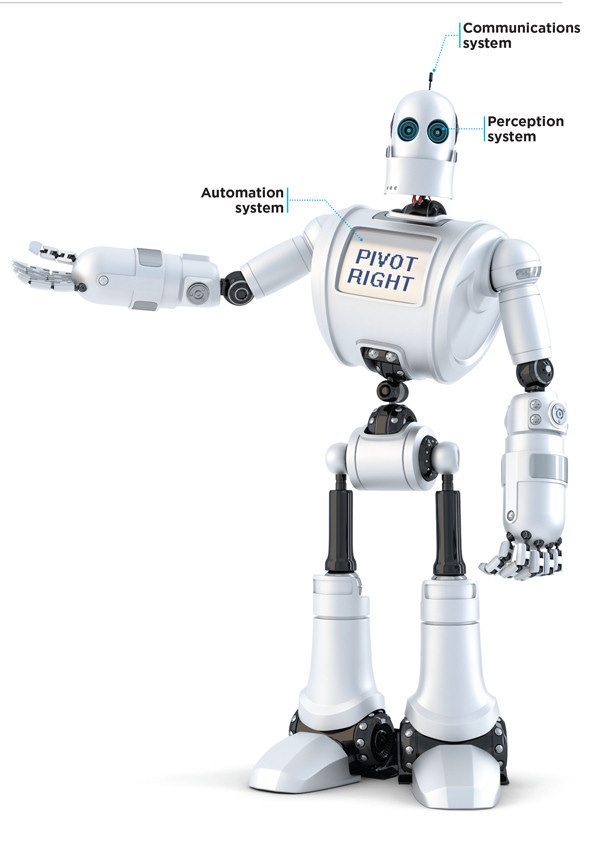

Stewart Moorehead, manager of John Deere’s robotic group, outlines what it takes to talk, sense and do chores, which we’ve boiled down into this diagram. Post it on your wall for reference when too much work has you shopping for your next hired hand.

• Communications system. “There needs to be a way for a remote supervisor to give the robot tasks and receive status information,” Moorehead says. “This can be achieved via cell signals or radio waves.”

• Automation system. This is what provides precision navigation and control over the tractor and its parts, such as the three-point hitch, selective control valves and the PTO. Moorehead says this step involves path planning, or charting where you would drive to complete a task; mission planning, or sequencing the series of events to accomplish a task; and resequencing, or instructing the vehicle how to handle the unexpected.

• Perception system. “A robot needs to perceive its environment to be able to interact with it correctly,” Moorehead says. “Are there any obstacles? Is this object a plant or a weed? LiDAR, cameras, radar and ultrasonics are all different technologies being explored.”

About the Author(s)

You May Also Like