August 15, 2019

The latest in manure handling technology was on display when the North American Manure Expo was held at Fair Oaks Farms in Newton County, Ind., recently. Both operators of large livestock operations and commercial manure applicators and their crew members attended the event to earn continuing education credits and to see the latest in manure application technology.

When it came time for application demonstrations, several rigs with the latest capabilities — including injection rigs behind liquid manure tanks that could pivot on the contour — showed what they could do in the moderately sandy soil in fields near the Fair Oaks Farms Adventure Center. Some rigs featured various systems for closing the trench after injecting manure.

There was one catch. For biosecurity reasons, the companies putting on the demonstrations agreed to apply water, not the real McCoy — actual manure. So, it wasn’t possible to judge how much injection cut down on odor, but it was possible to see how well the machines injected liquid beneath the surface and covered it up. Most companies chose to apply at rates they would normally apply when injecting actual manure.

Bazooka Farmstar demonstrated a sidedress rig that is supplied by a dragline hose. As long as corn is in the V1 to V4 stage, spokespeople insist there’s virtually no damage to the crop; the hose glides over it as the rig injects manure between rows.

Technology shock

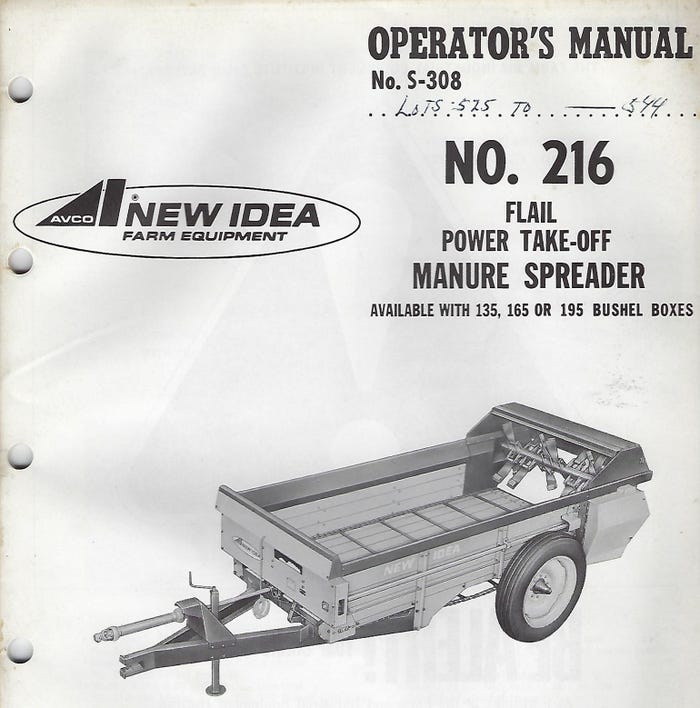

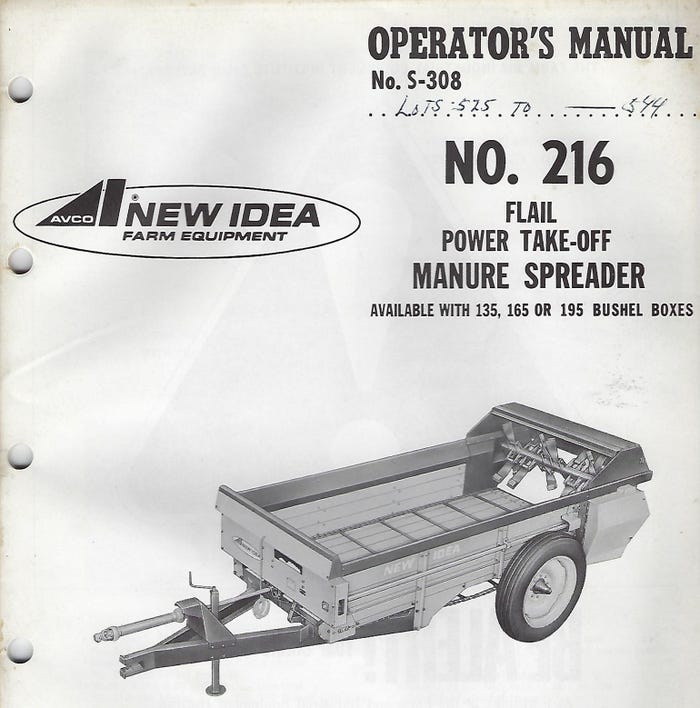

Once upon a time, or so it seems, New Idea was the king in manure handling equipment. The operator’s manual for the No. 216 flail spreader, dating back some five decades, says it was available in 135-bushel, 165-bushel or 195-bushel boxes. Large for the time, it was dwarfed by units operating at Fair Oaks during the demos.

STATE-OF-THE-ART … 50 YEARS AGO: New Idea was once the go-to name in manure spreading equipment. The PTO flail spreader featured on this operator’s manual traces back to the days when Avco owned New Idea. The New Idea name is owned by Agco today, but New Idea products are no longer sold.

Take the Ploeger Oxbo three-wheeled, self-propelled liquid applicator with injection unit on the rear, for example. It could inject a much larger quantity of manure in likely less time than the New Idea 216 model, even the 195-bushel size, could empty its load. The operator of the Oxbo machine demonstrated how it could turn without making big marks in the ground and showed off the advantage of flotation tires. In the days of the model 216 spreader, there were at least six tires on every pass: four on the tractor and two on the spreader.

Solid manure handling was more in vogue when the New Idea 216 came on the market. With today’s confinement units, liquid manure is more common. However, Ploeger makes and demonstrated an Oxbo version with a solid waste bed during the demonstrations.

You can learn more about Ploeger Oxbo equipment at ploegeroxbogroup.com. As for the New Idea 216 flail spreader, good luck finding a used one still in workable condition. New Idea, last bought by Agco, ceased operations over a decade ago.

Comments? Email [email protected].

You May Also Like