December 4, 2018

Darke County, Ohio, is home to Bear’s Mill. It is a supreme example of old-world technology and new-world enterprise. Built by Gabriel Baer in 1849, the mill’s turbines started turning in 1850. It has been running continuously, with the name change to Bear, since — with the exception of a period during the Civil War, when it was shut down to protect it from being destroyed.

Terry and Julie Clark purchased the mill from an elderly gentleman in 1978. He was to walk them through the milling process. However, between closing and time of possession, the seller died. This left the Clarks with no idea how the mill worked, except for knowing that sacks of grain were hoisted to the fourth floor and dumped down a hole, as the gentleman had pointed out one day. Starting from scratch, they poured small amounts of grain down the hole, tracking the grain through the various elevators and machines, learning as they went.

The 40- by 50-foot, four-story mill has a timber frame constructed from hickory trees felled within a 2-mile radius of the building site. The chamfered posts and beams are hewn, and the scantlings are sawn with a sash saw. The beautiful siding with a gray patina is black walnut, sawn into quarter-inch- by 8-inch flat boards attached to the structure with square-head nails. The windows are six-over-six panes of black walnut.

MILLSTONES: One set of the original millstones were imported from France.

The mill is powered by two turbines made by the Leffel Turbine Co. in Springfield, Ohio. Of the two sizes, the smaller, 32-inch turbine produces 23 horsepower; the larger, 40-inch turbine produces 33 hp. The water for the power is provided by Greenville Creek and approaches the mill from the dam, through the millrace, through the two turbines 10 feet under the surface of the water and back to Greenville Creek by way of the mill trace. From beginning to end, the water travels 800 feet and drops 7 feet.

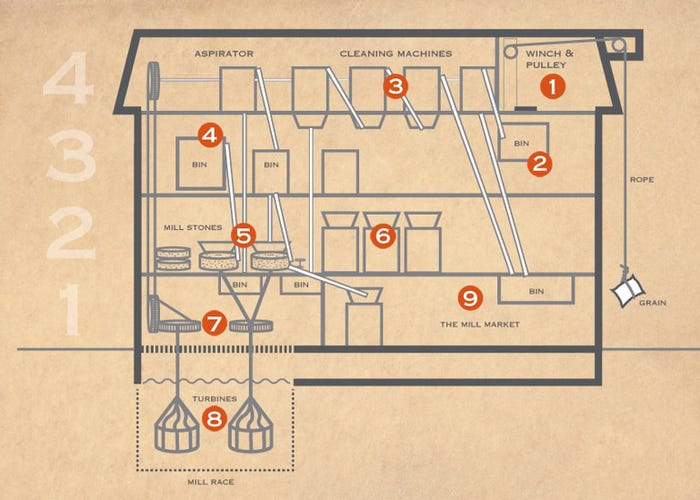

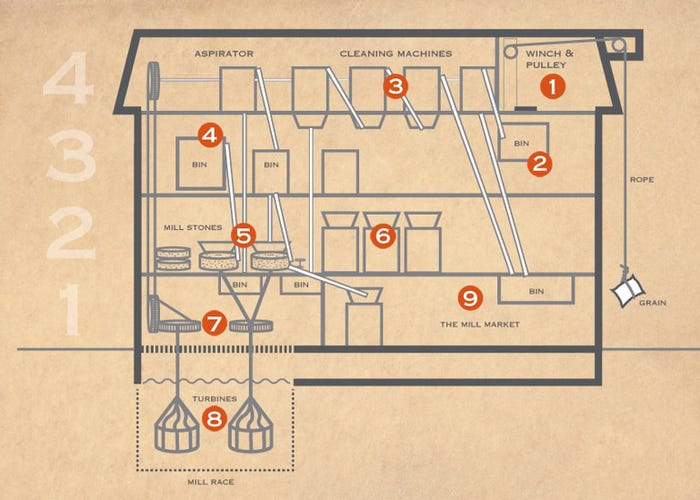

The turbines, in turn, power the line shafts powering all the equipment in the mill. On the fourth floor are the cleaning machines and on the third floor, the bins for storage. The second floor houses the buhrstones for grinding, and the first floor is for bagging and retail.

The elevators, made of belts and cups and gravity shuts, move the grain up and down between floors eight times to run through all the stages of the milling process. The two sets of buhrstones used in the mill today are the original stones. They were imported from France by Baer in 1848 at a cost of $6,000 per pair.

HOW IT WORKS: This illustration of the milling process shows how the grain travels through the mill to be ground into flour.

Still productive after 168 years

The mill’s interesting history continues into the new millennium as the mill still functions and continues to produce stone-milled cornmeal, whole wheat flour and rye flour in a new age, but with traditional Old World style.

Along with providing fresh stone-milled products, the first floor of the mill holds the beautiful Clark Gallery. Each month, the gallery features different local artists and their unique creations, plus culinary items and Julie’s beautiful pottery.

The mill offers self-guided tours, or group tours can be scheduled. The grounds around the mill are beautiful and provide walking trails to view the dam, millrace, mill trace and newly added timber-frame covered bridge crossing the millrace.

Bear’s Mill is now owned by Friends of the Mill; as a 501(c)(3) not-for-profit organization, its mission is to preserve, celebrate and share Bear’s Mill with the public. The Friends of the Mill took over running of the mill in 1999 and purchased it in 2013. The Clarks are still very active in the mill’s operation, though. Terry is the mill master and gives guided tours. Julie is the artist, and her pottery is displayed in the Clark Gallery.

For more information on Bear’s Mill and its events throughout the year, visit bearsmill.org.

I want to thank all who have read the barn articles over the last year. The response has been far greater than I ever expected. I enjoy talking to all who email and call. As the weather permits I will be hitting the road to meet and see many of you and your barns in person. Reach Gray at [email protected] or at 740-263-1369.

About the Author(s)

You May Also Like