August 19, 2013

Last week Gleaner unveiled the industry’s first Class 8 transverse rotary combine, part of its new S8 Super Series combines. The combine has a power rating of 430 hp that maxes out to 471 hp, making it Gleaner’s largest combine to date. All three new models in the series are designed to offer more hp and torque than the S7 series they replace to take advantage of the larger diameter rotor that came with the previous S7 series.

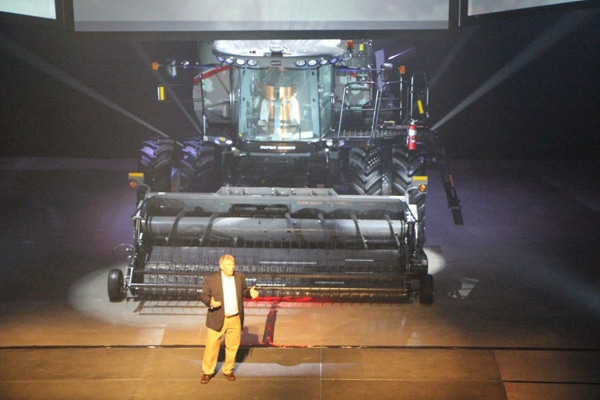

The unveiling took place at the Hartman Arena in Wichita, KS, 36 miles south of the company’s manufacturing plant in Hesston, where the combines will be built and then painted a new silver-gray to mark the new series.

“The truth is simple,” says Kevin Bien, Gleaner brand marketing manager, at the launch event. “For too long, the combine industry has confronted every challenge with horsepower, size, and weight. Combines keep getting bigger and more complicated. And farmers are told that this is the ante for more capacity. That’s not true. And we can prove it.”

Like what you’re reading? Subscribe to Farm Industry News Now e-newsletter to get the latest news and more straight to your inbox twice weekly.

The new S8 series is the second generation of Gleaner S combines. The first was the S7 series, which brought with it a larger dia. rotor that had 48 percent more throughput than previous Gleaners when it was introduced three years ago. To take advantage of the larger processor, engineers had to increase engine hp, which has been addressed with this new series, the S8.

“In any combine, if you change something in one place, it affects all the other areas,” Bien says. “So over the course of the last two years, we have been trying to get ready for the new S8.”

The biggest change with the new series is bigger engines. The top model, the S88, packs in 430 hp and reaches a maximum boost of 471 hp, taking the Gleaner line up to a class 8 size category. “Before, the largest rated horsepower on our combines was 370 with a maximum power boost of 398 hp,” Bien says. “So there’s a sizeable difference.”

Both the S88 and S7, the two largest models, are equipped with an 9.8L seven-cylinder engine. The smallest model, the S87, has a 322-hp 8.4L engine with a maximum boost of 390 hp. The engines are equipped with SCR and EGR technology to meet Tier 4 emissions standards without the need for a diesel particulate filter.

Kevin Bien says other combines may pack in more horsepower, but the Gleaner combine can get by with less hp and still match the same throughput. It does that by offering a simpler design that lowers the power drawn by functions unrelated to the core threshing and separating system, Bien says. Shafts and gear boxes maintain an inline design that doesn’t tie up power, so the engine doesn’t have to work as hard, Bien adds. The combine also weighs less than competitive models.

To harness the horsepower of these bigger engines, the rotor gear box had to be beefed up. The new gearbox is larger and is driven by bigger belts, which provide a wider overlap on speeds so you can finetune adjustments when crop conditions change. The same gearbox lets you manually reverse the rotor.

“Also, the pivot shaft pulling the belt got 27% larger,” Bien says. “So everything got touched.

Changes also were made to the feederhouse, cooling system and grain handling area to handle the increase in hp and higher flows of grain.

With the previous series, one complaint was the design of the clean grain elevator, which some farmers said was a bottleneck to getting grain in the tank. Gleaner addressed the problem in the new series by deepening the auger trough and lowering the cross auger to allow for higher flow rates. The new design also incorporates heavier paddles with a steeper pitch to move more grain up into the tank faster.

All these changes were addressed in this new series without adding weight to the combine, Bien says. “Gleaner combines are up to 12,300 lighter than competitive models. That reduces soil compaction by putting less pressure on the ground. The lighter weight also means the combine takes less fuel to run.”

During the combine unveiling, AGCO also cut the ribbon on a new $40 mill e-coat pain facility in Hesston. The new paint facility is where the new Gleaners will get their new silver-gray paint along with new decals, both unique to this series.

The combines will be displayed at fall farm shows. The suggested list price for the new combines (machine only) runs from $ 440,000 to $485,000.

For more information, visit www.GleanerCombines.com.

About the Author(s)

You May Also Like