April 22, 2019

By Darrell Boone

Purdue University Pesticide Programs Director Fred Whitford likens poly tanks to “expensive milk jugs,” but says it behooves operators to not forget about them during regular maintenance.

“This is important because insurance considers spills ‘pollution exclusive,’” he says. “If you have a spill because of a tank failure, your insurance won’t cover you.”

Whitford says avoiding spills begins with making sure you’re using the right kind of tank. Each poly tank has a tag that identifies it as a No. 10, 15 or 19, depending on density.

Tanks with a 10 designation are designed to hold the weight of water, or 8.345 pounds per gallon. Tanks with a 15 can hold 1.5 times the weight of water, or about 12 pounds per gallon, which allows them to be used as fertilizer tanks. Nuo. 19 tanks can hold about twice the weight of water, up to 16 or 17 pounds per gallon.

“If you put fertilizer in a tank that’s designed for water, you’ve stressed it beyond its engineering designs,” Whitford says.

Tank test

For older tanks, Whitford says sunlight is the No. 1 enemy. Tanks come with UV protection, but it breaks down over time and can lead to failure in a tank that’s either unduly weakened or used improperly. He suggests two simple tests to determine the integrity of tanks:

The pen test. Taking a water-soluble magic marker, Whitford says to color a small area of the tank at its key stress point and then wipe off the color. If the residue that remains shows that the tank is cracked or “alligatored,” that’s a sign it is starting to dry rot or fail.

The bat test. To further test how compromised a tank may be, Whitford tells operators to strike an empty tank with a baseball bat at its most stressed point. If it breaks, you know the tank needs to be replaced.

“I’m serious,” he says. “Better to break your tank with a bat than have it blow like an egg because you didn’t check it.” For more about the bat test, read the short commentary piece below.

Boone writes from Wabash, Ind.

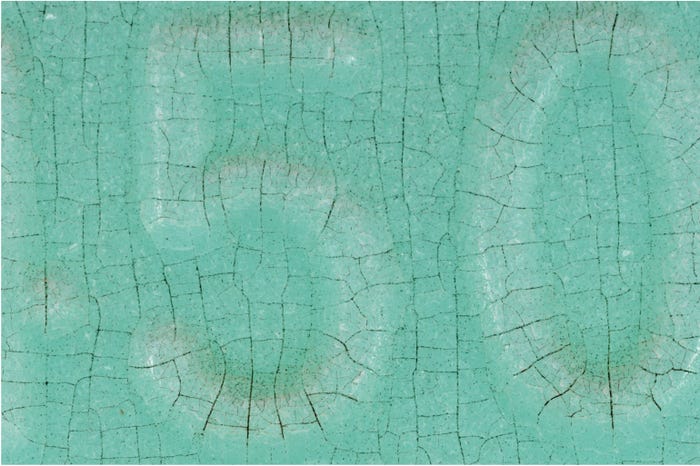

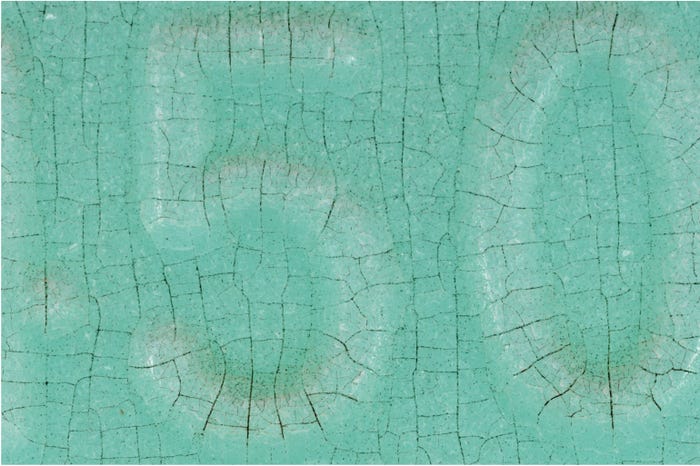

FAILURE LIKELY: A poly tank with this kind of checked pattern, which may only show up under close inspection, likely won’t pass Fred Whitford’s bat test.

Whitford at the plate!

When Fred Whitford suggests giving an older poly tank your best baseball swing, he’s not kidding. If you give him permission, he might do it for you. I watched him demonstrate at a pesticide training program.

He reserves the test for older tanks, especially those stored outside. Close inspection, perhaps with a pen test, as noted above, may reveal “checking” in the material. If a checked pattern appears, it’s a sign the tank is failing.

That’s when a bat test is in order, Whitford suggests. If you “strike out” and the tank holds, it still bears watching. Excessive checking suggests replacement would be prudent. If it’s a “home run” and the tank cracks, you just saved yourself headaches and money.

The message I left the demonstration with was that it’s much cheaper to buy a new tank than deal with the consequences when an older one fails.

— By Tom J. Bechman

You May Also Like