November 26, 2018

Sponsored Content

Agriculture sprayers are complete spray systems engineered for generating pressure to drive spray fluid from a tank out to the sprayer’s nozzle(s) to crop or soil. Sprayers feature a range of specifications that influence their performance abilities and suitability for specific work cases. Understanding the different sprayer models and their characteristics can help you select the best sprayer for the job. Ten common sprayer solutions are available in today’s industry: backpack, spot, ATV, UTV, tow behind, truck bed, 3 point hitch, boom, boomless, and mist. Sprayers can vary in their nozzle quantities, maximum PSI pressure and GPM flow rates, the sprayer pump type, tank gallon volume range, potential max spray coverage, system overall maneuverability, and total hose and nozzle reach. Sprayers are most often used for the administration of water, insecticides, pesticides, herbicides, and fertilizer. The cost of a sprayer ranges from $50 to $10,000, depending on the sprayer’s specifications.

Sprayer Selection Considerations

Know your job and what the sprayer will be used for; e.g. Perimeter treatments; spot applications; row crops; grow operations

Understand modern sprayer types, the model differences, and their optimum work use scenarios; e.g. Boomless sprayers for wide-swath coverage of hard-to-reach areas; mist sprayers for full-depth spray coverage; truckbed sprayers for high capacity, high pressure mobility

Determine the right sprayer’s performance specifications and equipment components

Determine any specific chemical compatibility considerations with the sprayer pump, hose, and gasket compatibility

Example Sprayer Selection: Vineyard pesticide use sprayer, 400 gallon truck-bed sprayer for increased hill mobility, featuring dual 300ft. hoses, dual high pressure nozzles, and 18 GPM max centrifugal sprayer pump.

Agriculture Sprayer Specifications

When you choose a job-specific sprayer to maximum spraying performance, it is important to know the requirements. There are nine variables in spraying applications that you should consider:

Spray Area Size

Spray Target and Spray Fluid

Spray Location and Terrain

Sprayer Fluid GPM Rate

Sprayer Fluid PSI Pressure

Total Spray Project Fluid Volume

Sprayer Tank Gallon Capacity

Spray Application Frequency

Spray Application Duration

Engineering

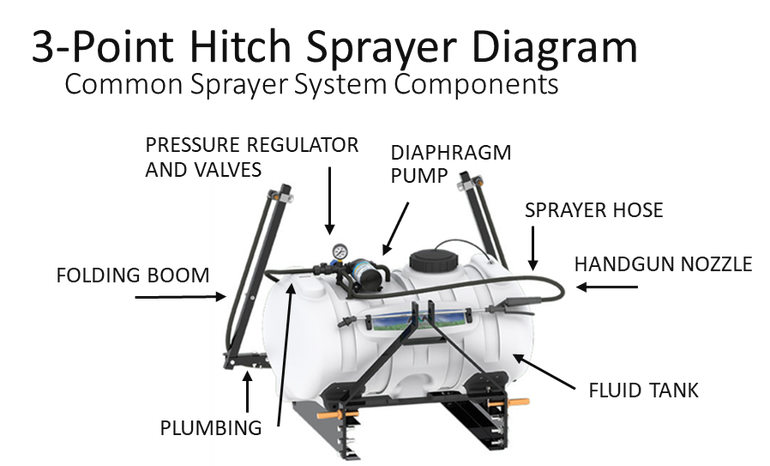

Sprayers are designed as full spraying systems with a pump and plumbing components to pressurize and drive the spray fluid from a tank and deliver to the spray nozzle(s) a consistent pressure stream optimized for the target application. To achieve this, these sprayer components are often used: pressure regulators, valves, in-line strainers, handguns, hoses and reels, and folding boom arms.

Engineers design sprayers with specific materials that must be compatible with the chemicals that are commonly used in agriculture spraying operations. Gasket materials and compatibility can vary within sprayer systems. Common sprayer materials include: high-density polyethylene (HDPE; fluid tank); steel (boom arms; pumps); stainless steel (fittings; handgun parts; pumps); PVC (polyvinyl chloride; plumbing); XLPE (cross-linked polyethylene, also PEX; plumbing).

Sprayer Performance and Operation Ranges

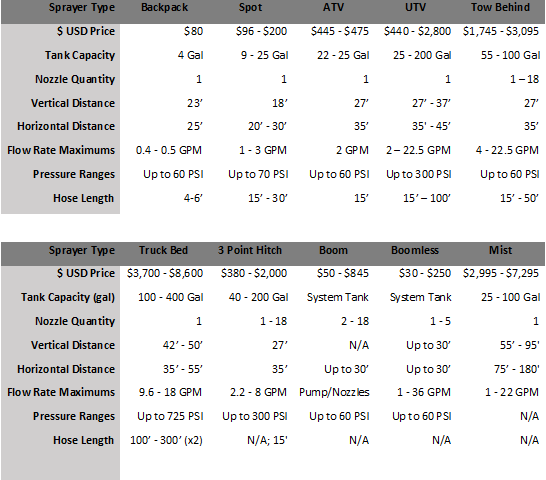

Each sprayer has different performance characteristics in terms of volume capacity, pressure and GPM flow rates, spray coverage, boom compatibility, and hose lengths. These characteristics dictate which sprayer is ideal for your application. Review the tables below to compare available sprayer specifications and associated costs:

Agriculture Sprayer Uses and Applications

Sprayers are heavily used in agriculture operations for crops, land, and livestock. Other industries that sprayers are frequently used within include: commercial applications of maintenance chemicals (such as with property line, landscape maintenance), groundskeeping (consumer, business, state/governmental), and the nursery and garden sectors of plant rearing. The following is an overview of common sprayer work applications:

Field, Row Crop Operations, Performance Chemicals

Irrigation, Fertigation for Pastures, Farmland, Orchards, Vineyards, Greenhouses

Multi-Scenario Pesticide, Insecticide Applications

Hard to Reach, Off Road, Rolling Land Spray Applications

Structural, Property and Fence Perimeter, Roadway Foliage and Pest Maintenance

Livestock, Pastureland Insect, Plant Pest Control

Fire Response, Burning Control

Manufacturing Line Spraying of Production Solutions

High Pressure, Target Spotting, Washing, Cleaning

Types of Sprayers

Backpack Sprayers

Smallest and most versatile, mobile, and precise of all sprayer models, allowing for spot access to difficult access areas. They are designed to be carried via cushioned shoulder straps for high mobility. Commonly utilized for small, repeat, target foliage, garden and landscape plants, perimeters, structures, and pest maintenance.

Backpack sprayers are often hand-priming and feature 4 gallon tank capacities, 0.4 - 0.5 GPM nozzle flow rates, and max pressures up to 60 psi.

Spot Sprayers

Multi-use, small transportable sprayer featuring a full spraying system: tank, pump, plumbing, and handgun nozzle. Spot Sprayers have been designed for repeated target spot applications and are often attached to utility vehicles, riding mowers, tractors, etc. for transport across property or between job sites.

Spot sprayers have 12V diaphragm sprayer pumps and feature 9 to 25 gallon tank capacities, 1.0 - 3.0 GPM nozzle flow rates, hoses up to 30ft for extended spray nozzle reach, and max pressures up to 70 psi.

ATV Sprayers

Highest maneuverability of all sprayer models for access across rough terrain. ATV sprayers are full system transport sprayers often used for property holders with distant or long stretches of spray targets located where it is not readily accessible or practical by other means. Commonly utilized for administering spray fluid chemicals for perimeter, rangeland, and livestock maintenance.

ATV sprayers have 12V diaphragm pumps and feature 22 to 25 gallon tank capacities, 2.0 GPM nozzle flow rate, hoses up to 15ft, and max pressures up to 60 psi.

UTV Sprayers

High mobility, full spraying systems featuring large capacity tanks and potential for high pressure delivery. Designed for UTV mounting to provide sprayer access through the utility vehicle’s off-road abilities. Often used in commercial, agriculture, and residential operations for extensive groundskeeping activities, due to the UTV sprayer’s boom and boomless sprayer attachment capabilities and increased tank capacity. Designed for compatibility and use in irrigation of water and plant growth, pest maintenance chemicals.

UTV sprayers have either 12V diaphragm pumps or gas-powered centrifugal pumps for greater GPM and nozzle psi, and feature 25 to 200 gallon tank capacities, 2.0 - 22.5 GPM nozzle flow rates, hoses up to 100ft, and max pressures up to 290 psi.

Trailer / Tow-Behind Sprayers

Engineered as a trailer spraying system with wheels and towing attachments for tow-capable vehicles, ATVs, UTVs, and tractors, often for sprayer system transport between job sites. Trailer sprayers are designed to provide boom and no boom capabilities in a ball-hitch, tow-behind deliverance package commonly used for fairly large area irrigation/fertigation applications.

Tow behind sprayers have either 12V diaphragm pumps or gas-driven centrifugal spray pump to increase GPM or pressure, and feature 55 to 100 gallon tank capacities, 4.0 - 22.5 GPM nozzle flow rates, hoses up to 50ft, and max pressures up to 290 psi.

Pickup Truck Bed Sprayers

Greatest capacity, max pressure range, and hose length range of all sprayer types. Pickup truck sprayers are a complete system mounted to a utility skid for maneuverability and loading. Designed for large volume, large coverage spray jobs, especially those requiring precise and/or pressurized application. Truck bed sprayers are often used for vegetation control, commercial landscaping, groundskeeping, vineyards, orchards and tree groves, extended vertical reach applications, emergency fire control response, and pressurized cleaning/washing operations.

Pickup truck bed sprayers have gas motor centrifugal sprayer pumps and feature 100 to 400 gallon tank capacities, 9.6 - 18.0 GPM nozzle flow rates, hoses up to 300ft with a dual nozzle/dual hose reel (300’ x 2) model available, and max pressures up to 725 psi.

3-Point Hitch Sprayers

Great versatile sprayer featuring category one, 3-point hitch attachment mechanisms for quick and simple vehicle connections. They are often equipped to farm, utility tractors, powered by PTO, but can be fitted to any category one, three-point attachment package. Largely designed for boom and boomless nozzle integration for increased area coverage of spray fluid or water across row crops, pasture acreage, late season tall crops. This sprayer can also feature handgun nozzles for target spot use, and are often used for commercial, contracting work scenarios involving athletic sports fields, park and recreational groundskeeping, and roadway, ditch applications.

Three-point hitch sprayer systems have 12V diaphragm pumps or allow for self-provision of a sprayer pump to match work-case requirements, and feature 40 to 200 gallon tank capacities, 2.2 - 8.0 GPM nozzle flow rates, hoses up to 15ft, and max pressures up to 60 psi.

Boom Sprayers

Modern inventive advancement of the single spray nozzle to a system with up to 18 nozzles, covering up to 30 feet of spray area with the largest of boom attachment arms. Boom sprayers are extendable, folding arms with equally spaced nozzles designed for the bulk administration of a spray fluid. They are engineered to install on various vehicles as well as sprayer tanks, pumps, and nozzle heads, system components many boom models need fitted with prior to use, especially if seeking specific flow rates or nozzle output.

Boom sprayers are often fitted with diaphragm or roller sprayer pumps, but other sprayer pump models can be used. Booms feature from 2 to 18 nozzles, range from 4 to 30 feet, and have flow rate and pressure maximums dependent on pump type. Commonly used boom lengths are 12ft, 20ft, and 30ft.

Boomless Sprayers

Also known as “No Booms,” boomless spray nozzles are engineered for increased distance and wide swath spray projection. No boom nozzles feature versatile vehicle mounting for mobile spray delivery up to 30ft, often in fan-type coverage patterns. Common vehicle installation is on small tractors, utility vehicles, farm tractors, ATVs and UTVs. Well-operated boomless sprayers potentially provide significant spray coverage and can be very useful and cost-effective in applications. They are commonly used for spray access to areas that are hard-to-reach by vehicle or other sprayer types, especially booms, with examples being dense vegetation, tree lines, tall grass and crops, ditches, levees, roadway right-of-ways, and perimeters.

Boomless sprayers require a self-provided sprayer pump and are commonly used with diaphragm or roller pumps. Tank capacities, flow rates, and max pressure varies with the system installation and the boomless nozzle capabilities. No boom nozzles are available in 1 to 5 nozzle tip quantities, for multi-directional spray coverage, and capabilities of 1.0 - 36 GPM flow rates and max pressures up to 60 psi.

Mist Sprayers

The greatest spray coverage among the sprayer models, the engineering of mist sprayers further distributes spray fluid molecules into smaller-sized droplets to produce a fine spray mist that increases the fluid’s coverage abilities across its spray targets. Designed for versatility and uniformity in work scenarios, mist sprayers are well-suited for trees, crops, shrubs, and general vegetation as in fruit and nut trees, groves and orchards, berry bushes, row crops, tall crops, and thick tree lines.

Mist sprayers are full sprayer systems powered by PTO mount roller pump or a gas powered centrifugal pump. They are often mounted to utility tractors as well as ATVs/UTVs, and have 25 to 100 gallon tank capacities, 1.0 – 22 GPM nozzle flow rate, a vertical distance reach up to 95 feet, and a horizontal distance reach up to 180 feet. Mist sprayers feature cannon volute nozzles for dispersed, targeted spraying that is capable of 210°degree rotation for full left and right alternation.

Agriculture Sprayer Takeaways

Agriculture Sprayers are engineered with equipment, components, and performance specifications designed to maximize their work potential across the many scenarios in agriculture, commercial and small business, industry production lines, and residential property grounds. Sprayers are commonly used for the administration of water and water/chemical solutions, often fertilizers, pesticides, and herbicides.

When it comes to selecting sprayers and their equipment, consider the details of your spray project and any related work requirements in terms of the spray system’s tank volume, max pressure and distance capability, nozzle type, nozzle quantities, mobility, and GPM flow rates. Some sprayer models may also require selecting a sprayer pump with compatible specifications. The right sprayer for the job will blend the work needs with the capabilities of the sprayer system.

Whenever needing sprayers and associated components such as nozzles, pumps, or system parts, Sprayer Supplies is the industry’s choice for providing the American-crafted, quality trusted by the agricultural industry, commercial spray operations, and individual farms and property owners. For any questions, further information, and for any additional requests concerning sprayers and their equipment, contact Sprayer Supplies today.

About the Author(s)

You May Also Like