October 4, 2017

This is a media release sent by manufacturers and agriculture businesses then distributed directly from them.

When people think about tires, they often think “round, black and made of rubber,” and seldom give them a second thought. So the engineers at Firestone have identified five common misconceptions about agricultural tires that could make a big difference for you in the field, and even to your bottom line.

1. Unless They’re Starting to Look Flat, There’s No Need to Check or Adjust the Inflation Pressure

In reality, tire inflation pressure is paramount to tire performance. It doesn’t just carry the load, inflation pressure impacts everything from tire wear to fuel efficiency to traction. So by not diligently checking and using the right inflation pressure, you really aren’t getting the most out of your tires, which could be costing you in wasted time or energy.

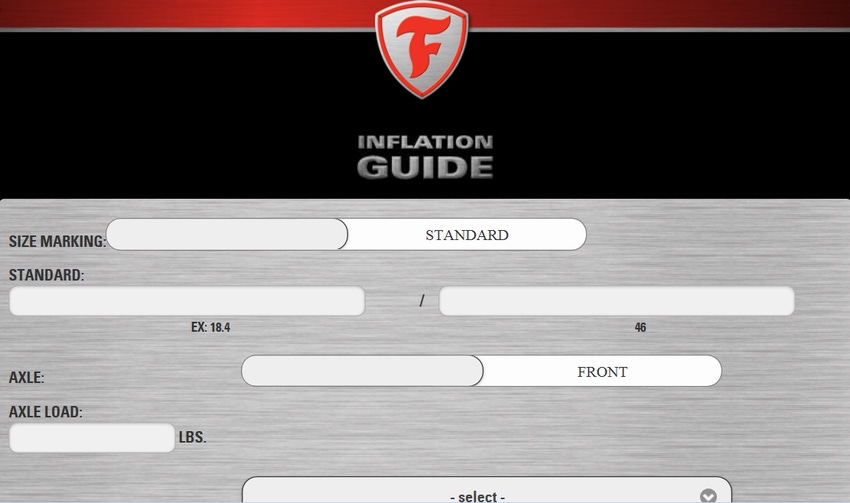

The key to using correct inflation pressure is to know your axle weights. Take a few minutes to weigh your equipment, and then use an inflation calculator to properly determine what inflation pressures are right for the load you are carrying. Over-inflation can reduce the tire’s footprint, which reduces traction. In fact, Firestone has demonstrated in field studies that tires gain a 5% improvement in traction* when using the correct inflation pressure. Under-inflation can cause the tire to deflect too much, which can cause tire damage, waste fuel, and ultimately result in a premature need to replace tires.

2. Tire Technology is All the Same

There may be a few differences in the way tires look, but generally speaking, they do all have common traits. However, IF and VF technology in tires is really starting to become more popular because it is technology designed for today’s heavier equipment. IF and VF technology allows farmers to carry a heavier load using the same inflation pressure as standard tires, or the same load using a lower inflation pressure. This results in less pressure on the soil, which reduces soil compaction. And in this day and age, every yield advantage is needed, so IF and VF tires are a good investment for the farm.

3. Power Hop in the Field is a Result of Poor Tire Quality

Power hop occurs in soils that are dry and packed. Power hop in the field can be annoying, but can easily be fixed. Power hop has very little to do with the quality or type of tire itself, and can be corrected by adjusting the inflation pressure.

The first step in correcting power hop is to make sure the weight split is correct for the type of tractor, and the tire inflation pressures are set based on axle load. If the tractor is weighted and tire pressures are set correctly, increase the inflation pressure on one axle. For front-wheel-drive tractors, increase the inflation pressure 6 psi on the front axle. For four-wheel-drive tractors, increase the inflation pressure 6 psi on the rear axle. After the soil has received rain, the inflation pressures can be reduced back to the minimum inflation pressure.

4. Road Lope is a Result of Tire Tread Design or Tire Technology

Tread design does have some impact on vibration levels when driving on the road, but not enough to really be noticeable. If you are experiencing road lope, or bouncing when traveling on the road, it is usually a function of an out-of-round tire/wheel assembly. In most cases, a quarter-inch of out-of-roundness will cause the tractor to bounce as it goes down the road. To fix this condition, the high spot of the tire/wheel assembly must be indentified. Once the high spot is indentified, it is placed at the 12 o`clock position and the wheel bolts are loosened. This allows the tire to center on the axle and the wheel bolts are re-tightened.

5. Tires Should be Made Stronger to Avoid Stubble in the Field

The fact is, there is no rubber hard enough to withstand corn stubble. On a durometer scale, corn stubble registers around 90 to 110, while rubber registers around 68 to 75. Rubber tires require a certain amount of flexibility so they can do their job. But that also means that crop stubble will win every time in a head-to-head battle. At this time, no tire is manufactured with material that can totally resist stubble damage.

Our recommendation is to use stubble stompers to push over the crop. When the crop is lying flat, there is a lower risk of tire puncture when driving through the field.

*Based off of findings from a 2014 Firestone test in Des Moines, Iowa, using John Deere 8R tractors over a distance of 1,000 feet. Tires included in the test were Firestone 420/85R34 Radial All Traction DT and Firestone 480/80R50 Radial Deep Tread 23, inflated at proper levels (15 psi on rear tires and 16 psi on front tires) and over inflated at 30 psi on both sets.

You May Also Like