September 25, 2014

T-L Irrigation announces a new patented technology that combines “the simplicity of hydraulics with the continuous movement of a T-L to improve water application efficiency.

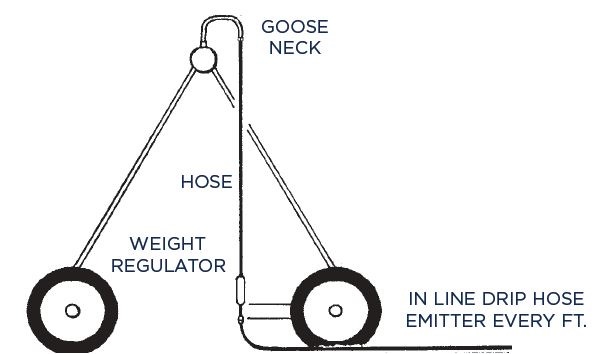

This new application is called Precision Mobile Drip Irrigation (PMDI) is a union of center pivot technology with drip irrigation. PMDI consists of in-line drip hoses spaced at 60 inches, 40 inches or 30 inches and combines the efficiency of surface drip irrigation (95 percent) with the flexibility and economics of center pivot irrigation.

PDMI offers two primary advantages: Overall water efficiency and dry wheel tracks.

The drip line design eliminates evaporation and wind drift associated with traditional sprinklers because wind will not affect it as it applies water at 95 percent efficiency, providing the efficiency of surface drip at the much–reduced cost per acre price of center pivots.

In many soils and cropping practices, deep wheel tracks on pivots and linear systems create problems. With PMDI, drip lines apply water behind the wheels so tires run on dry ground.

The system replaces nozzles or sprinkler heads with in-line drip hoses that are dragged by the center pivot or lateral-move system. As the hoses are pulled through the field, emitters deliver an even water pattern across the full length of the pivot or linear system.

PMDI technology combines the lower cost of center pivot irrigation with the proven efficiency of drip irrigation to achieve water efficiency near 95 percent.

You May Also Like