Even if you were faithful about calibrating your yield monitor, you still may need to do some postharvest “cleaning” on your data. “Otherwise, it may not be as accurate as you think, and if you use it to make decisions, it may impact your conclusions to some degree,” says Bob Nielsen, Purdue University Extension corn specialist.

Nielsen cleans a considerable amount of yield data, usually from whole-field trials, after each harvest. He has put together three comprehensive articles on potential errors that might lurk in your yield data, and what, if anything, you can do about them. In many cases, you can make corrections. In other cases, you may decide not to rely on certain pieces of data. In all cases, you can adjust before next harvest season once you know what errors can pop up in your data.

You can find Nielsen’s stories and other pertinent information at the Chat ‘n Chew Cafe website. Here is a closer look at each topic, with a direct link to each one:

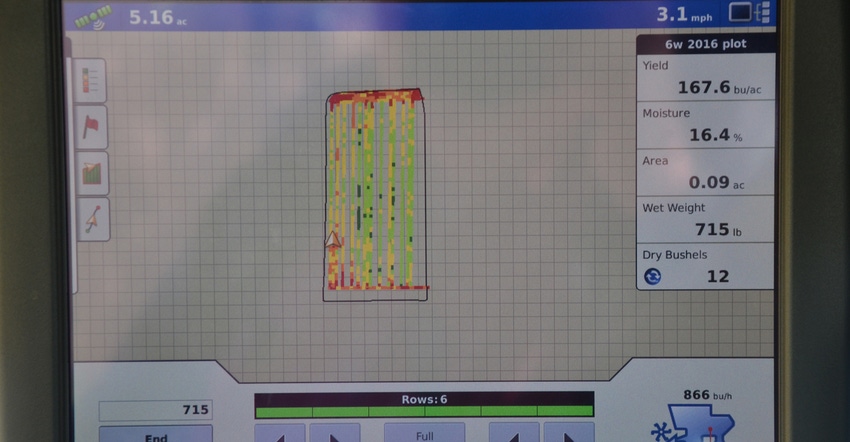

“Gremlins” in yield monitor data that need to be eliminated. Certain settings influence estimates of dry bushels per acre and spatial accuracy of the data points in relation to their actual, georeferenced location within the field, Nielsen says. Common postharvesting steps that he completes to make sure the yield picture is accurate include choosing the correct settings for dry bushel moisture value, dry bushel weight and stop/start time delays, which can affect estimated total harvested area. Others include checking grain flow lag time, which is the time of travel from the header to the sensor, which can affect accuracy of point data, and the GPS offset distance from the GPS antenna to the header, which also affects accuracy of point data.

You can either purchase software and do cleaning yourself or hire someone to do it. Make sure you hire a competent person, and don’t assume just because data went from the combine to a cloud-based service that it’s cleaned. See Cleaning Yield Data.

Wandering hybrid syndrome. This can become an issue if you put two hybrids in opposite sides of the planter, labeled them at planting and then want to compare them after harvest. Even if you labeled hybrids correctly in the monitor, a 5- to 15-foot error in actual location can make the yield monitor think it is into the other hybrid. Such an error is possible, Nielsen notes, if you’re using a less accurate differential GPS signal for harvest, like WAAS, and a more accurate signal, like RTK, when planting.

You can remedy this for the future by upgrading everything to RTK or better accuracy. In the short run, you may have to live with inaccurate data. See Auto Hybrid Errors.

Wandering swath width syndrome. Some newer yield monitors automatically adjust header width if you’re combining point rows, and one or more header rows pass over an area already harvested. Inaccurate differential GPS signals can cause inaccurate automatic header width adjustments in yield monitors with this feature, Nielsen says. In turn, that can affect accuracy of yield estimates. It’s a neat feature, but it can lead to error, especially if you’re using something less accurate than RTK.

An option for the future is to turn off the automatic feature on point rows, and set header width manually, Nielsen says. See Auto Header Width.

About the Author(s)

You May Also Like