May 8, 2020

Editor’s note: Timothy Terry, farming strategic planning specialist with Cornell Extension, has compiled three stories’ worth of information on robotic milking systems based on visits to dairy farms in New York. This is the second story in the series.

I was recently invited to participate in a robotic farming discussion group.

The evening began with a few presentations by a robot manufacture that, surprisingly, were less about sales and more about startup and management of the systems and the cows.

These proved to be good fodder for a useful discussion amongst the technical service people, dairy farmers and other industry people in attendance, including myself.

The next day, we visited three farms currently using robotic milking systems — two in the Finger Lakes and one in western New York. Both the discussion and the tour brought to light some interesting concepts regarding robotic milking systems.

I managed to glean several pages of notes on these concepts, and in the next couple of weeks I’ll try to distill them down into something more manageable to take home.

Here are some of the things I’ve learned about sizing robotic milking systems and what types of systems can work best for your dairy:

Sizing and pens

First, minimize the obstacles to and from the robot.

There should be a minimum 8 feet of clearance at the entrance and exit of a single robot, but 14 feet between robots in tandem.

Sort pens are difficult to size. Of the three farms we toured, none utilized sort pens as each farmer thought they would be empty more than 80% of the time and that the money would be better spent in strategically placed gates and manger headlocks.

Fetch pens — where you gather cows that haven’t visited the robot lately — are best kept small and temporary.

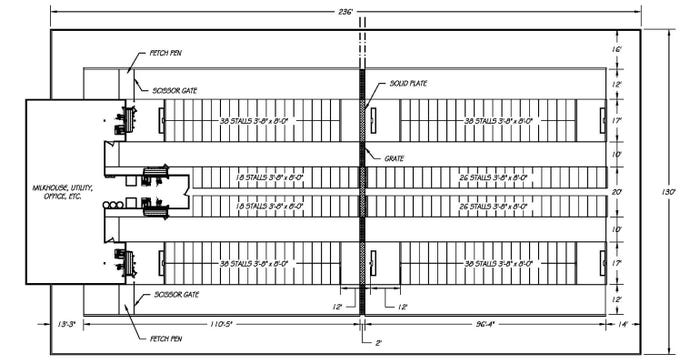

Below is a diagram of a system setup that could work.

When you fetch a cow, you want to put it in the robot right away so the cow gets the idea that it’s important to go to it. Generally, you’ll fetch the cows only one or two at a time.

Placing the cows in a small pen will encourage them to enter the robot ASAP. Blocking entrance traffic from the rest of the herd until the fetch cows are milked will help speed this process. It is likely that a cow will have to be fetched because it is a little timid. By blocking other traffic, it leaves the cow more comfortable to enter the robot.

The fetch pen should be temporary only in the sense that once the fetch cows are milked, the gates can be lifted or swung out of the way so that the entrance is not obstructed. That said, whether sorting or fetching, it’s important to think strategically about placing the gates. By opening or closing the right gates, one person should be able to easily sort or fetch a cow.

Robotic milking system barns tend to be much quieter. As such, the cow’s behavior becomes more docile and workable, so sorting or fetching is not usually the rodeo it used to be when cows were gathered up two to three times a day.

In some cases, the cows become obnoxiously friendly, which means servicing a waterer or circulation fan can become a mob scene.

Free flow vs. guided flow

With few exceptions, a free-flow system works better than a guided-flow system.

In free-flow, a cow can get up and get a drink or a bite to eat and then lie down, which maximizes lying time. In guided-flow systems, the cow must go through the robot before or after its meal in order to lie down again. Depending on the traffic at the robot, this will increase its standing time and cut into the cow’s lying time. It could also contribute to slug feeding behavior as it may opt for only a few large meals hours apart to avoid going through the robot.

This also puts additional, unproductive pressure on the robot because the cow will have to cycle through it, and this takes time away from other animals going through the robot.

Keep water nearby

Place waterers right outside the exit of the robot.

Just like in a parlor, cows will drink most of their water immediately after milking. However, this waterer should be at least 10 feet away — 15 feet is better — from the exit to not hinder cow flow.

Shoot for 60 cows max

Figure a robotic milking system to service a maximum of 60 cows. Do more than this and wait times will increase and daily visits will decrease. You want to aim for that 2.8-2.9-visits-per-cow daily target.

In practice, 55 to 58 cows per robot is better, especially in higher-producing groups or herds. This will allow the cows to cycle through comfortably, including those peak production animals coming four to six times a day, as well as give you some downtime for daily maintenance.

Start a robotic system at only 80% capacity — less than 50 cows per robot. This will give the cows time to learn the robot and vice-versa. Cycle times for each cow will be longer until they get used to the sounds and sensations associated with the system.

Don’t limit visitations during the first few days. If a cow wants to visit 19 times, let it, but you may want to limit grain feeding after the third or fourth visit. The robotic milking experience should be as pleasurable as possible.

Switch by groups

Switching to a robotic milking system doesn’t have to be all or nothing. In fact, switching in a group-by-group manner will make the transition easier while also taking some pressure off the existing system. This may get you a few more years out of that aged parlor, giving you a way to milk those older cows that are more likely to refuse the robots.

In smaller herds the group-by-group option may not work. However, starting with a small group of early lactation cows and then adding to the group as cows freshen in may work better.

Terry is a farm planning specialist with Cornell Extension’s Harvest NY program.

Read more about:

Robotic Milking SystemsYou May Also Like