You probably learned this fact in school if you took an ag class in Indiana. Indiana ranks second only to California in quantity of processed tomatoes grown and produced annually.

Recently, Indiana Prairie Farmer visited Steve Smith, longtime senior director of agriculture for Red Gold, at Orestes, Ind., to learn firsthand what’s involved in growing, harvesting, processing and distributing tomatoes.

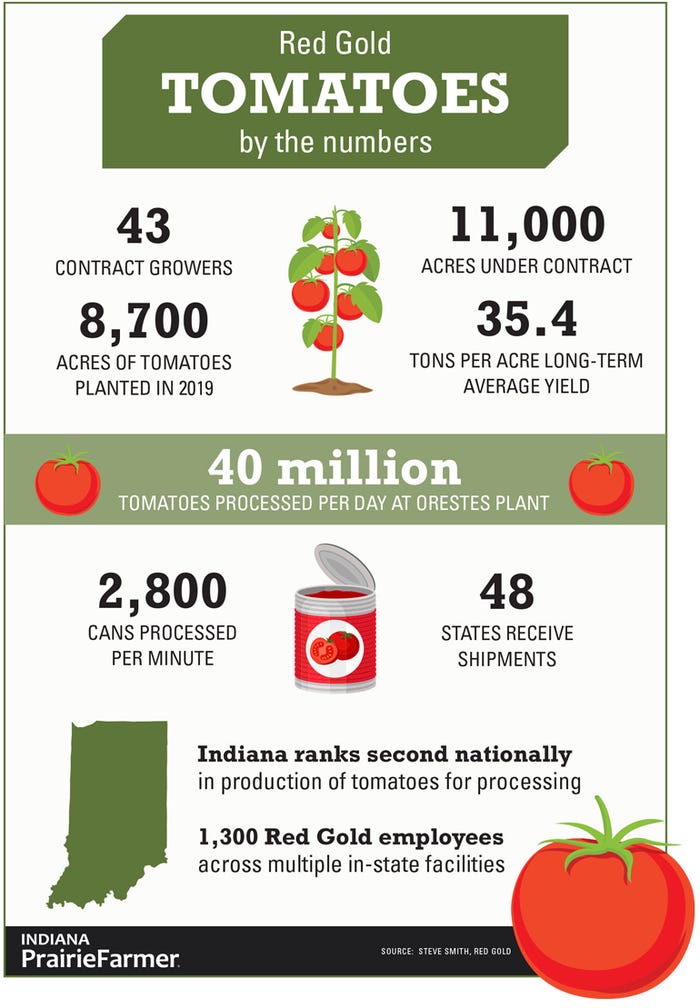

Red Gold is Indiana’s processed tomato producer, contracting with 43 growers to grow about 11,000 acres of tomatoes per year. The wet spring trimmed that to fewer than 9,000 acres this year.

Here’s a closer look at how processed tomato production operates in Indiana:

The company. Red Gold was founded in 1941 and is still family-owned today, Smith says. The company has three plants that handle tomatoes out of the field, called the fresh-pack season. Those are located at Elwood (along with the company headquarters), Orestes and Geneva. Red Gold also has a distribution facility near Orestes and a trucking company based in Elwood. It contracts with 43 growers and employs 1,300 people.

The tomatoes. These tomatoes are bred for commercial harvest, Smith says. They are special varieties of a Roma type of tomato. “They’re firmer than what you would grow in the garden,” he explains. “When they’re approaching being mature but not quite, they’re still green on the outside but already turning red to pink on the inside.”

Red Gold arranges for transplants to be shipped to each grower according to planting schedules. The schedules are staggered so there should be a constant supply to the various plants once the fresh-pack season begins until it ends, assuming weather cooperates.

Growers are scattered across Indiana. About half of contracted acres are irrigated. Tomatoes don’t like wet feet, so if a farmer has heavier ground, pattern tile is almost a must.

Field harvest. Either Smith or one of his staff members coordinates with the grower when harvest approaches. “They may have different varieties or they planted at different times, so they most likely won’t harvest the entire crop at once,” Smith says.

A mechanical tomato harvester is around a $360,000 investment new, much like a combine, Smith says. Growers own their harvesters. Typical harvesters pull in whole plants, two rows at a time. Until just a few years ago, it took 10 to 12 people to ride onboard to sort on the go. Today’s harvesters are equipped with color sorters, so it only takes three to four people onboard to sort.

Delivery to the plant. Growers truck semiloads of tomatoes in special trailers to the plant, Smith says. “The driver weighs in, a member of the Reg Gold agriculture staff visually inspects the load, then the driver drops the trailer and heads home,” he says. “Our employees hook to each trailer and take it to the dumping area.”

Cleaning begins while tomatoes are still in the trailer. Large amounts of water flush through the tomatoes, removing dirt. The water is recycled several times while the tomatoes are still outside the processing facility.

Processing. Color sorters aid workers in removing tomatoes as they move toward peeling beds. A treatment helps loosen up peelings before tomatoes reach mechanical peelers.

“We also pull what we call ‘brix’ samples during this stage,” Smith says. “It’s sort of like test weight for corn or beans. It’s a measure of sugar content in the tomatoes.”

Once tomatoes are peeled, they’re sent to sorting lines where they pass through an electronic color sorter again and are separated by size. Peels are collected and sold to be used in dog food. Tomatoes that are not suitable as a whole-peel tomato but still salvageable are diverted for use in sauces.

“We buy large bins of tomato paste from California for our off-season production of things like sauces, juice and ketchup,” Smith explains. “We produce those products year-round. During the fresh-pack season, tomatoes which don’t make the grade for canning also go into sauces.”

Cans and more cans. Shiny steel cans move quickly along various assembly lines. At the right time, they’re filled and sealed. Then cans are mechanically grouped into the desired quantity and packaged on pallets.

“We don’t label our peeled, canned tomatoes on the assembly line,” Smith says. “They go into storage, and labels are applied later once customers place orders. We pack for many different labels.”

So, if you buy a name brand versus a chain label brand, are you getting the same product? “It all depends on what the buyer wants,” Smith says. “Sometimes they’re the same, and sometimes they’re not. We have different grades of tomatoes, and some brands will ask for a different grade. The Red Gold brand is reserved for premium tomatoes.”

Labeling and more. An entire large room is devoted to storing labels, Smith says. When it’s time to label, they’re applied with glue along a seam by machine. Some sauces are processed while fresh-pack tomatoes are coming in, so labels are applied on sauce products even while most of the day’s production is left unlabeled. The unlabeled lots on pallets are coded and numbered. They can be traced back to the grower, Smith says.

Don’t miss the infographic below, and click through the slideshow to see photos of the Red Gold operation.

About the Author(s)

You May Also Like