Sam Knott of Atticus likes to think of corn and soybeans as little corn and soybean factories. They’re designed to do a job and will respond depending on what a grower does or doesn’t do to them.

When it comes to corn, if everything goes perfect — great weather, perfect soils, the right population and the right amount of fertilizer — it could theoretically yield 660 bushels per acre. But nothing is perfect, of course — far from it.

“Everything we do positively or negatively to the corn crop factory, we don’t add bushels, we’re preserving the potential that’s already in the factory when we plant it. If a corn factory has a bad day, we lose bushels,” Knott says.

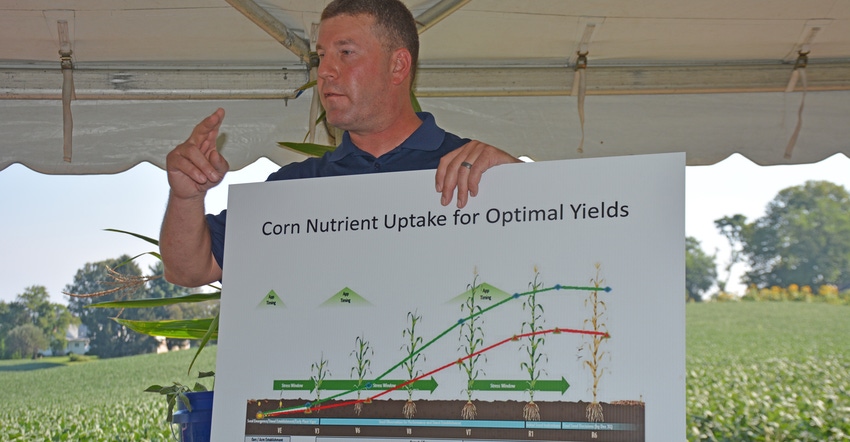

Knowing the stages of corn and soybean factories is key to preserving that yield potential using nutrient management, pesticides and herbicides, Knott told a group of growers attending The Mill’s annual crop showcase in White Hall, Md.

Yield — at least for grain corn — is all about ear size, and that ear size is determined at the early V stages.

“What’s crucial to know is that factory is in a very important reproductive stage, so if you don’t use the right product or the right rate or the right timing, just what can you give your corn factory? A bad day. So review your rates, review your products,” Knott says.

V3 to V5 is the first critical stage of reproduction.

“That ear that you’re going to harvest 90 to 110 days after that is already determining the number of rows around the dominant ear that you’re going to harvest,” Knott says. “At V5, can we do anything to add rows onto this ear you’re going to harvest? No. But if that factory has a bad day, you can lose rows. This is the investment you all are putting a lot of time and energy into, so these are the stages you have to monitor and do the right things for the factory.”

Between V5 and V10, every collar will produce an ear, but a dominant one will eventually emerge.

V10 is critical, Knott says, because this is the stage that determines the number of kernel sets on each row. There is nothing you can do after V10 that will add more kernels onto the row. “But guess what, if a corn factory has a bad day, you can lose kernels,” he says.

Know when to feed

From V5 to V10 is when the corn is establishing its canopy, the start of likely the most crucial time for the crop.

“But what’s happening is that from the time we get to tassel to the time we get to ear fill, your factory is going to consume 85% to 90% of its macro and micronutrients for the entire year,” Knott says. “So that’s the nitrogen you put on.”

“The reality of it is, if I know when 90% of my investment is going to be consumed, I stop and I think about that last two years or the last 10 years,” he says. “Am I doing what that factory needs out of convenience for me, or the right timing or return on investment for it? Should I be thinking about putting on nitrogen later in the season because my crop, my factory, needs it the most then? Should I be looking at disease control?”

By the time you get to those later stages — milking, denting — it’s all about pumping carbohydrates and sugars to boost test weights.

“But there’s a story to tell,” Knott says. With fall just around the corner, he says this is the perfect time to look at fertility, weed control and starter fertilizer programs.

“If you talk to anybody around the planet that sets record yields in any state for the yield contest, a couple of key things they do: nitrogen, nitrogen, nitrogen, but they dial it in for their factory when it needs it the most,” he says. “The other thing they do is they manage diseases. They do not allow disease to ever have a negative day in their corn factory.”

Managing the bean factory

Soybeans are different than corn in many ways. One trend Knott has seen on farms is earlier planting dates to take advantage of longer daylight.

Once summer solstice arrives June 20-22, the plant automatically triggers its reproductive stage.

“So if you plant late beans, they generally don’t get real tall before they start to flower,” Knott says. “They don’t get that chance because they immediately want to go reproductive. So when you think about your residual programs you put down for herbicide control for soybeans, you think about your post herbicides.”

Once it goes reproductive, the soybean is going to do the same thing as corn: consume lots of nutrients.

The things Knott tells growers who want to max out soybean production is to control weeds and diseases, and look back at their history to calculate ideal plant populations.

But something growers might not be thinking about is looking at nitrogen.

“You don’t think about soybeans needing N, but for every bushel of soybeans, on average, that factory needs about 5 pounds of nitrogen,” Knott says. “Now beans will produce their own N through rhizome bacteria, nodulation, manure applications, residual N from the soil, or sometimes you have to look at ways to make a manual application to the beans for an extra boost.”

Potassium is another key item to think about.

“If you don’t have a proper nitrogen-potassium ratio to your crop or coming out of the soil, it’s like a radiator in the truck, which is a 50-50 blend of antifreeze and water. It doesn’t work with one or the other out of balance, and you’ll have a problem,” Knott says. “You got to think about your little factories not just when they consume the macro and micronutrients, but am I properly feeding that crop?”

About the Author(s)

You May Also Like