October 14, 2019

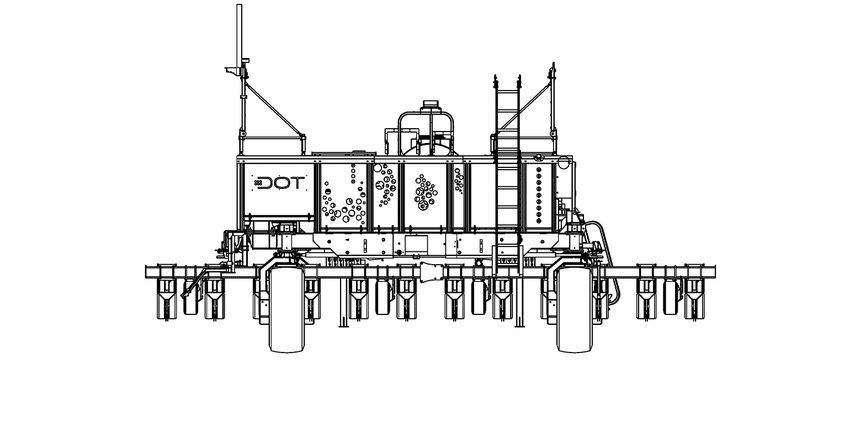

Autonomous machinery is gaining more attention as the prototypes get better and companies move forward with enhanced designs. Dot Technology Corp, a Canadian company, has been moving ahead with its “cartridge-based” approach to autonomy. A key to the machine is implements added for farmer use.

First in that development cycle was a SeedMaster seeder, second a Pattison Connect sprayer and then a New Leader spreader. Now comes a SeedMaster row crop planter.

The new planter was developed with technology from SeedMaster and the row crop expertise of Frank Prince of Capricorn Bay Ltd., a Precision Planting dealership in Manitoba.

The planter’s design includes 12 rows with 30-inch spacing and provides two tank configurations: one 50-bushel seed tank with two 425-gallon liquid tanks; or two 50-bushel seed tanks with one 425-gallon liquid tank.

The planter uses Precision Planting electric meters and includes variable-rate liquid fertilizer options, too.

Farmers at a Canadian farm show in September saw a toolbar version of the planter run without seed boxes or liquid tanks. A prototype was used in the spring to plant, says Norbert Beaujot, president and founder, Dot Technology. “We used the unit to prove the concept,” he says. “We’re using a Precision Planting controller, but we won’t be in a market-ready position for spring.”

Prince, who is working on the planter’s development, does plan to have a full unit in the field in spring 2020 to plant. As the Dot machine moves closer to commercial release, the planter will be an important tool to have on hand.

There are about six Dot units on farms now doing a variety of work, Beaujot says. Those implements link easily using ISOBUS, but he adds that working through the ISOBUS connection with a planter is more complicated. And those details are being worked out.

It’s a planter

Ask Prince about the new implement, and he cuts to the chase: “This might sound stupid, but it’s a planter, it does what it’s supposed to do, and it has all the precision toys on it. It has turn compensation, auto swath — and you give it a speed and tell it where it is in the field, and it puts seed in the ground correctly.”

What more could a farmer want than a machine that — on its own — goes into the field and gets the job done?

The communication challenge of linking a planter to the autonomous platform is a hurdle for development of the prototype, but Prince is working through that with Dot. His family has been on the innovation curve for some time. “We’ve been growing corn here for 15 years or longer under irrigation,” says Prince, who’s farm is near the U.S. border in southern Manitoba. “We were the first to raise corn and soybeans this far west.”

Prince works with Precision Planting and has been a dealer in the region for some time. His work with Precision Planting has included development of a proper disk for canola planting, a first for that company. Prince’s father, a longtime attendee of the National Farm Machinery Show, likes getting row crop ideas in the winter, and the family applies them where they make sense on the operation.

Prince’s involvement with the new Dot-enabled planter involves getting the iron and the electronics to talk to each other. It’s a process he’s working through.

Working with robots

When talking automation, many observers are enamored of the driverless machine moving through a field on its own. But there are logistics to running a machine that also have to be worked out with a robot. For Prince, whose fields are contiguous and large — many are 400 to 500 acres in size — an autonomous tractor left to its own devices makes sense.

“We’ve talked [using autonomy] a lot of different ways,” Prince says. “When we plant now, we have two to four operators, depending on the spring. With four Dot 30-foot planters, we could have just two operators babysit them, and they could run 24 hours a day.”

That all-hours operation can help overcome weather hurdles to planting, too, and Prince’s model cuts labor needed in half. That doesn’t mean they lay off two people, but it does mean redeploying two people to be more efficient elsewhere. “The jobs would be reallocated,” he says. “It’s harder to get skilled operators. We could use them elsewhere, and less-skilled workers could watch the planters.”

When it comes to tending, Dot’s Beaujot offered an interesting comment: “You could put the Dot in the field to plant and go home to bed. When it’s done, it would stop, and you could return the next morning. And in that time, you’d have gotten a few more hours of planting done. It still makes you more efficient, even if it doesn’t run all night,” he notes.

As for the future? Prince sums it up: “Autonomy is coming to the farming world.”

Learn more about Dot Technology Corp. by visiting seedotrun.com.

About the Author(s)

You May Also Like