It won’t be in the near future, but a researcher at Michigan State University is possibly onto something big when it comes to curbing crop losses during drought years.

Kyung-Hwan Han, professor in the MSU horticulture department, discovered a gene in a weed that when overexpressed, produces drought tolerance in plants. This gene, from the Arabidopsis weed that is related to cabbage and mustard, can be used in all kinds of crops. Han is further testing it in corn.

“As a scientist at a university, it is my job to create new knowledge and options for farmers,” he says. “According to publicly available data, the U.S. experienced $17 billion in crop losses due to drought in 2012, and I don’t think it will go down in the future. Drought conditions will come and go. It’s a major concern for farmers. This technology will protect their crops.”

From his basic finding of how the Arabidopsis tolerates drought, it took him just over 10 years to prove how the plant did it and to figure out a physical way to transfer the gene into corn. He’s been tweaking its effectiveness and last year established “proof of concept” in greenhouse experiments. He’s now ready to bring the technology to small field trials this growing season.

“Crop scientists would love to have a solution to providing drought tolerance. Industry is trying to come up with that ability. It is very difficult and complicated, but I believe our technology will bring about a breakthrough,” Han says.

How it works

On the underside of leaves are stomata, or holes, that allow carbon dioxide to enter the plant and, through photosynthesis, make carbohydrates, or food. The holes also allow for transpiration.

“If you can find a way to close the holes, transpirational water loss is minimized,” Han says. “But if the stomata stay closed, how will it grow? So, we developed another technology that allows this gene to only be expressed during drought conditions.”

Han says other drought-tolerance tech exists, but they’re not as effective. “We tweaked the naturally existing mechanism in the plant to have advantages,” he says.

“This technology will protect the plant, but without any growth penalties often associated with drought tolerance. Under drought conditions, the plant would close the stomata to minimize transpirational water loss, but would resume its normal function when drought is over.”

The two mechanisms work together. Han calls this his Xerico technology. It has been shown to enhance drought resistance of both monocot and dicot crops, and has been successfully tested in potatoes and rice.

MTRAC helps transition

A factor advancing Han’s research is the Michigan Translational Research and Commercialization (MTRAC) Innovation Hub for AgBio at MSU.

Started last year as a successor to a more limited program, the program supports the translation of cutting-edge AgBio research into innovative companies, which have potential for high growth and job retention to promote a culture of innovation, discovery and entrepreneurship in the state.

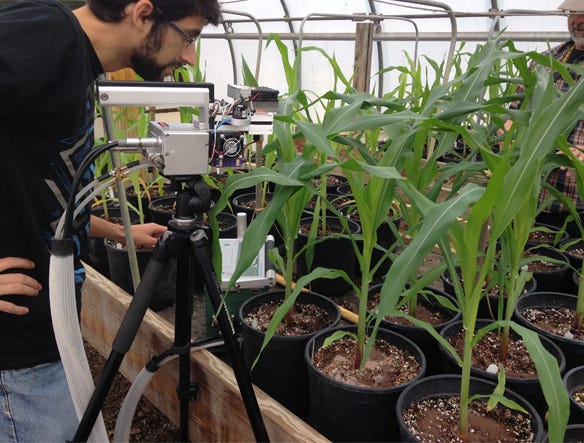

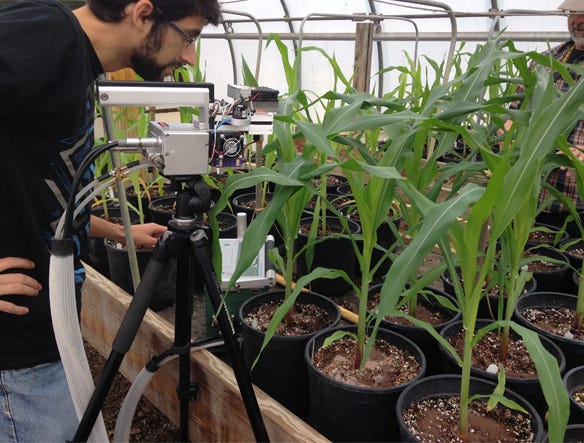

FROM LAB TO FIELD: Jesse Traub, chief technology officer at Kopess AgTech LLC,

measues photosynthesis of Xerico corn plants. Kyung-Hwan Han’s research is

going to be transferred from the greenhouse to in-field tests this spring.

Han says MTRAC is helping him to transition his work into actual real-world use. “I am most qualified to do the research, but I don’t have the business expertise to get it commercialized.”

Karen Studer-Rabeler, commercialization program director for MTRAC, says a gap exists between what the federal government funds through basic research grants and what industry, or even what a startup, would be able to take forward to commercialization.

“We fill that gap by providing funding for key activities, as well as guidance through that process,” she says. “We take research to the point where somebody may be able to take it on in the commercial world, essentially ‘de-risking’ it.”

Funding comes from MSU and through the state’s Michigan Strategic Fund, which is administered by the Michigan Economic Development Corp.

From lab to market

“Dr. Han’s work is an excellent representation of the importance of translational research being done at our universities through this program,” says Denise Graves, university relations director for MEDC.

“Advancing Michigan-based university projects and accelerating ideas and technology, like the work of Dr. Han, from the lab to the market, is exactly what the MTRAC program is designed to do and why MEDC continues its investment and commitment to early-stage research,” she says.

The statewide Innovation Hub program began in April, and MSU was designated a hub in June. The first five awards were given in September. For a few years before that, MSU had an MTRAC awards program that was only for its faculty.

With the hub now statewide, any researcher from any institute of higher education, hospital system or nonprofit research institution can connect with an innovation hub to take its product or idea from research to the marketplace. However, proposals from outside of MSU are required to bring matching funds.

The hub initiative is expanding, as the state establishes itself as the place to create and grow a business by providing high-tech startup companies with access to critical resources, such as funding and expert counsel, from idea to maturity.

In addition to MSU’s Inno-vation Hub, another is the MTRAC Life Sciences Innovation Hub at the University of Michigan, which focuses on human health.

Studer-Rabeler says MEDC hopes within the next two years to have additional hubs in advanced transportation, advanced materials and biomedical sciences.

“The state wants to attract and increase the number of jobs,” Studer-Rabeler says.

“We want to encourage and help startups. For the university, it is really an extension of our land-grant mission — to share our knowledge and technologies that are being developed here with others at-large — in this case, the ag community.”

Financial resources

The Innovation Hub at MSU was funded with a total of $2.27 million — $1 million from MEDC and the rest from MSU sources — for the next two years.

An oversight committee, mainly of industry leaders with some university personnel, make funding decisions and receive progress reports.

Funding is awarded at two budget levels:

• Tier 1 — up to 100,000 per year, awarded in March

• Tier 2 — up to $25,000 per year, awarded at different times of the year, currently September and January cycles

Eleven new grants were recently announced. Go online to see a list of those projects.

Moving forward

In 2014, Han’s work with drought tolerance received a Tier 2 award. Last year, he received a Tier 1 award. He has also received funds for his work with poplar trees.

By using MTRAC to verify and de-risk his Xerico corn technology and to cultivate additional seed, $250,000 in federal commercialization funding has been secured for field testing this year.

“Large companies want field ‘proof of concept,’” Han says. “Without MTRAC funding, I would not have likely gotten this far.”

If proof of concept is achieved in the field, the next stage would be to test the technology at multiple sites in different states and to identify what germplasms work best.

Han says commercialization is likely to be at least five years out. “But I’m happy to be where we are and advancing,” he says. “Without MTRAC, I had no idea how to move forward. They coached me every step of the way.”

By using MTRAC to verify his Xerico corn technology and cultivate additional seed, he was able to secure $250,000 in federal funding for field testing this year. This next step, if successful, is to attract additional investors. “Large companies want field ‘proof of concept,’” Han says. “Without MTRAC funding, I would not have likely gotten this far.”

If proof-of-concept is achieved in the field, the next stage would be to test the technology at multiple sites in different states and to identify what germplasms work best.

Han says commercialization is likely to be at least five years out. “But I’m happy to be where we are and advancing,” he says. “Without MTRAC, I had no idea how to move forward. They coached me every step of the way.”

POPLAR TESTING: Kyung-Hwan Han is conducting research on producing

faster-growing and higher-density poplar trees for harvest. The idea is

to harvest the perennial crop every two to three years.

Poplar trees as a crop?

Can you imagine harvesting a crop of poplar trees every two to three years? Kyung-Hwan Han, a researcher at Michigan State University, sees it as an opportunity to create a new revenue source for farmers.

Han has secured grants through the Michigan Translational Research and Commercialization (MTRAC) Innovation Hub for AgBio at MSU.

His research is focused on producing faster-growing and higher-density poplar trees for harvest. He is the inventor on multiple patent applications for the technology and is using the hub to advance his work toward commercialization.

“It’s very relevant to Michigan farmers,” he says. “It’s a new type of crop they can grow on marginal land or farmland otherwise not suited for traditional crops. This crop can be a very good alternative.”

Han says the trees can be planted as a normal stick by just shoving it in the ground. “It’s easy to propagate and grow,” he adds.

The perennial tree could be harvested every two or three years using a tractor with a modified header — just like any other crop. “You don’t have to replant for 10 or more years,” Han says.

The biomass could be used for biopower generation, making the crop into wood chips or pellets, which he says are gaining huge popularity globally.

“In terms of agronomy, it’s not that difficult,” he says. “The challenge is making wood biomass profitable to produce. By increasing yield and quality of biomass, it has good potential.”

At this time, Han doesn’t have the data to predict profitability, but by using greenhouse data, he expects a 20% to 30% increase in yield over non-modified trees.

By advancing his research through MTRAC, he was awarded a $250,000 federal commercialization grant to continue his work in field trials.

About the Author(s)

You May Also Like