The Dobson family tried a new microbial product on the farm designed to replace synthetic, and totally flipped their nitrogen management upside down.

For years, Mark Dobson used the blanket approach when applying nitrogen — one rate, one product across an entire field. But that was not resulting in uniform yields. His son, Lance, soon returned to the farm in 2011 after graduating from the University of Missouri in Columbia.

During his final college years, Lance took a soils class. There was a lot of emphasis on both the chemical and physical properties of the soil, he says. The course looked at rates of phosphorus, potassium and nitrogen and how each affected yield.

Lance started collecting and analyzing data and found fields were just not getting the nitrogen response. Enter Pivot Bio Proven, the first nitrogen-producing microbe commercially introduced in 2019. The father-and-son duo tested it in their fields and found Proven to be good for the soil, crop and environment. They recently made a whole farm switch to this microbial nitrogen source rather than synthetic.

Early ag tech adopters

Mark’s grandfather came to this region of west-central Missouri in 1932 during the Great Depression and started farming as a sharecropper. His dad and uncle finally purchased the farm in the late 1950s, so he started on the farm at an early age. “It was a chore to keep the weeds out of soybeans,” Mark shares.

In the first grade before the Fourth of July until school started, he recalls, “Every day, I would cut weeds out of soybeans.” Being so close to the agronomics of a field for so long, Mark began to make changes in his operation to increase productivity, save resources and be conscious of the environment.

The journey to incorporating new crop management practices into the farming operation started back when mapping software was DOS-based.

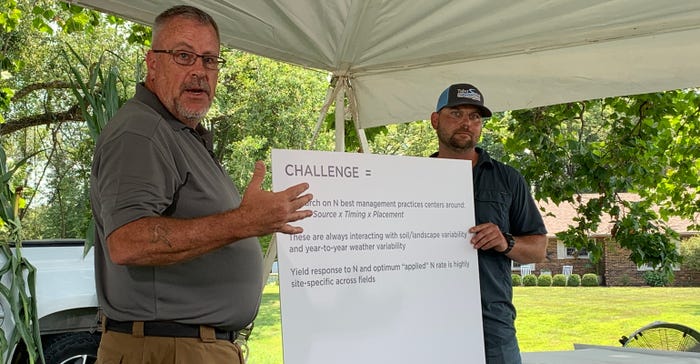

PROVEN PROCESS: David Hughes (left), Pivot Bio technical services manager, and Lance Dobson explain the challenges with nitrogen staying on the farm fields in Missouri. Hughes has been working with the family for years to adopt new crop management practices.

In March 1995, the Dobson farm west of Lexington, Mo., was one of the first non-research farms to use GPS soil testing and variable rates to spread fertilizer in this region of the state. That year, they had one of the first yield monitors installed on their John Deere 6620 combine.

“There was no fancy screen, just push-button LED,” recalls David Hughes, the family’s Pivot Bio technical services manager. The result was a collection of soil fertility and yield data to create a precision ag management zone for prescription recommendations in the year to follow.

Today, the farm continues that tradition of testing and adopting new practices in crop management systems, such as moving away from synthetic nitrogen into the realm of microbial.

Add new data

At one time, Mark says, the family would use blanket fertilizer on fields. Then they decided to grid soil-test and apply only the fertilizer needed to correct the pH of the soil. Finally, they saw where the high-yielding areas were on the farm and exactly what the soil fertility was at that location. But Lance notes that just because a field has high fertility levels, it isn’t always your highest-yielding area of the field.

“I look at the areas of the field where in the past we had lots of biology go over, whether that'd be livestock, or if there's a cornfield that hadn't eroded over time, and it has higher organic matter,” he explains. “It may have lower full test values, but actually will yield more bushels per acre.”

It was a dilemma that made him look closer at why the farm was spending time and money to improve phosphorus and potassium levels, but that was really not the yield limiting factor for the field. He says it points back to a lack of understanding on biology of the soil.

Change up nitrogen

The Dobsons created an on-farm research trial assessing the differences in nitrogen management practices from microbial versus synthetic.

Before 2021, the nitrogen management practice included 180 to 200 pounds of anhydrous with stabilizers applied in the fall. “But there is a lot that can happen from November all the way up until May and June,” Lance says. So, they talked with Hughes about Proven.

Hughes says that typically when agronomists look at nitrogen best management practices on the farm, they target four categories — synthetic fertilizer rate, source of fertilizer, timing of application and uptake of nitrogen. The Dobsons focused on source and rate. “We changed source by actually adding a biological source of nitrogen with the Pivot Bio Proven to replace synthetic nitrogen fertilizer,” Hughes explains.

PROMOTING PRODUCTS: Ernie Sanders, Pivot Bio vice president of product development, talks about Proven N 40, the second-generation microbial nitrogen product in the company’s line. It is designed to replace current synthetic nitrogen in the marketplace.

With the Dobson’s new equipment, the Pivot Bio Proven went on with the planter pass, placing it right at the root for nitrogen fixation.

Hughes says growers using Proven are seeing a reduction in standard nitrogen practice by 20 to 29 pounds per acre. They are also seeing an increase in yields of up to 3 bushels per acre. But the key, he adds, is the amount of nitrogen taken up by the plant.

A two-year study by Pivot Bio found Proven showed whole plant use of 38 pounds per acre in 2019 and 39 pounds per acre in 2020.

Future of microbial N

In 2022, Pivot Bio will offer a 40-pound product that allows farmers to replace up to 40 pounds per acre of synthetic nitrogen, Hughes says — almost double the performance of Pivot Bio’s first Proven product launch.

“All of this type of research to identify where can you reduce those 40 pounds of synthetic, which is good for the grower, good for the environment, brings value, and still have the highest-yielding crop you can have, this type of research is going on all across the entire country,” Ernie Sanders, Pivot Bio vice president of product development, says of the second-generation product.

The company has similar studies in New York with dairy farmers, along with Nebraska and Iowa. It is all part of the Pivot Bio mission to help growers along with improving soil, water and air quality.

Adding microbial nitrogen products only continues the farm’s tradition of keeping conservation top of mind, Lance says. His dad has been no-till farming since the 1990s to keep the soil out of watersheds. “And we’re trying to continue that through keeping our nutrients on the farm,” he adds.

For Mark, these new nitrogen management products are like “icing on the cake” for a farmer who for decades worked to increase productivity, save resources and be conscious of the environment. “It is about leaving the land better than you got it for the next generation,” he says.

About the Author(s)

You May Also Like