October 3, 2022

Improving management of fertilizer and crop protection products starts with improving the information available to the grower and dealer. Amvac has developed the Ultimus platform, designed to track crop protection products and fertilizer from manufacturing to application.

It will be some time before it comes to market, but Amvac is turning tech it developed for application into a high-end tracking tool.

“With us, it starts with the premise that application equipment doesn’t know what’s being applied unless someone tells it,” says Rick Rice, director of application technology at Amvac. “With Simpas, we learned how to deliver product information from the product container to the application equipment.”

The tech is the company’s Smart Tag system, part of an infrastructure for the Simpas in-furrow application system that Amvac launched in the market a few years ago. But looking at the Smart Tag system, Rice says Amvac and its tech folks saw another opportunity: creating a way to track and communicate product use from start to finish. The result is a new tool under development called Ultimus.

“With the societal desire for increased transparence about how food is grown, we believe there’s an opportunity to take the technology and process that we developed for Simpas and apply it basically to any type of application equipment,” Rice says.

He notes using the Smart Tag approach with equipment would actually be simpler to manage than with a Simpas application. In that system, a 24-row planter will have as many as 72 cartridges at a time, each with its own tag. With Ultimus, the system would track a single machine and the product applied.

Software and application intelligence

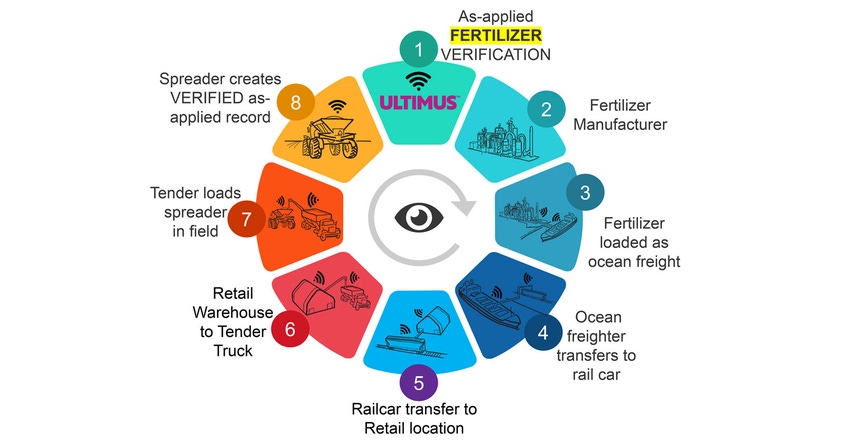

Often a software idea developed for one use has utility in other areas. That’s the benefit of Ultimus. The Smart Tag software that reads information from the tag to track product use — and knows what product is associated with the tag — has bigger potential benefits. Rice explains that fertilizer loaded into a freighter would have a Smart Tag with quantity information attached.

When that fertilizer is off-loaded at a terminal and parsed to rail cars, for example, the tag on each rail car will be updated with product and quantity information coming from the tagged terminal containers. This process continues linking product type with the amount used or transferred right to the spreader hopper on the farm.

This works because Amvac has developed a system defining a container broadly, allowing tracking capability as the product is parsed from ship to rail car to spreader. “What we’ve secured patents for is the process of tracking crop input contents all the way through the supply chain to include the geo-tagged application record,” Rice says.

He's quick to add that Amvac’s patents don’t create barriers to anyone putting a tag on something and tracking it through the supply chain. “But what we’ve done is secured patents that define tracking through the supply chain for the purpose of creating a verified application record,” he says.

The Ultimus system uses RFID tags rather than bar codes or QR codes as a way of transferring information. Rice explains this is more reliable given that sometimes it’s hard for a reader in different conditions to see a bar code or QR code. With these passive tags, they’re only active when the reader nears them, transferring key information along the way. That means the Smart Tag doesn’t have a battery and never runs down. And it’s a writable tag, allowing the transfer of information from and to the tag.

Accurate measure, no operator

This new platform that mates RFID tags with software for sharing information all along the manufacturing supply chain can boost the veracity of information gathered, Rice says. Several industries, from fertilizer to petroleum, track volumes of product used and try to track where they’re used.

A system like Ultimus would create an infrastructure of tracking that doesn’t involve the need for the operator to enter any information. The tag already knows what’s in the container or tank along the process. That information is easily passed from the tank to the application controller without the operator having to look up anything.

For example, when a tender loads a sprayer with 1,000 gallons of material, the Smart Tag on the tender is read by the sprayer, which knows the volume loaded. The tender also knows what’s off-loaded to the sprayer. This two-way information passing is all done without the operator entering any data or using shorthand to describe the product supplied. The result is more accurate information across the chain.

Ultimus is a new concept for the industry that Amvac is moving forward to develop and market. The company, which has innovated the application industry with Smart Box tech and Simpas, doesn’t see itself as a just crop protection company. “We’re evolving to add software and precision ag technology services, and we have tools the industry can use,” Rice says.

It may be some time before farmers see Ultimus tech available for their farms, but news of its availability shows that new tools are coming to make tracking and traceability easier for farmers across a broad range of products.

About the Author(s)

You May Also Like