March 21, 2012

Chemical additives that help agricultural pesticides adhere to their targets during spraying can lead to formation of smaller "satellite" droplets that cause those pesticides to drift into unwanted areas, Purdue University researchers have found.

Chemical additives that help agricultural pesticides adhere to their targets during spraying can lead to formation of smaller "satellite" droplets that cause those pesticides to drift into unwanted areas, Purdue University researchers have found.

Carlos Corvalan, an associate professor of food science, said understanding how the additives work together means they could be designed to decrease the health, environmental and property damage risks caused by drift. Corvalan; Osvaldo Campanella, a Purdue professor of agricultural and biological engineering; and Paul E. Sojka, a Purdue professor of mechanical engineering, published their results in a February issue of the journal Chemical Engineering Science.

"When we spray liquids, we have what we call main drops, which are drops of the desired size, and we can also have smaller satellite drops. The smaller drops move easily by wind and travel long distances," Corvalan said. "Now that we know better how additives influence the formation of satellite droplets, we can control their formation."

The research will also have applications in food processing and rocket propulsion, where drop sizes are important.

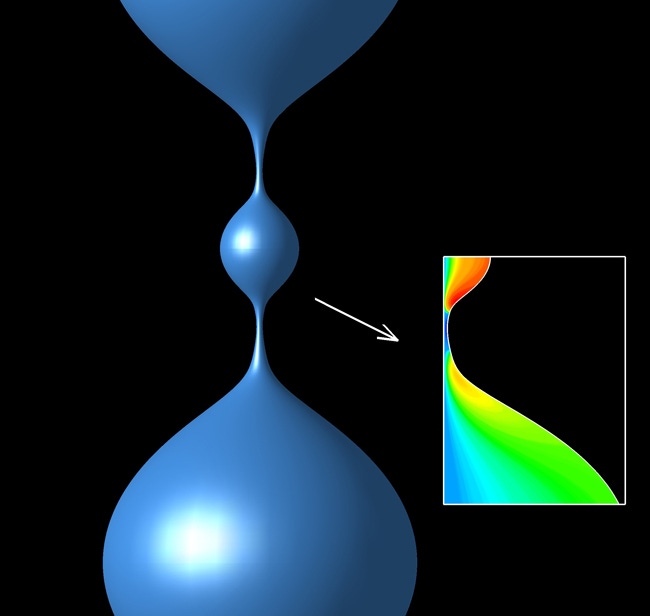

When liquids are sprayed, they start in a stream and eventually form drops. As the liquids move farther in the air, drops connected by a thin filament start to pull apart. That filament eventually detaches and becomes part of the drops that were forming on either side of it.

Satellite droplets form in the middle of filaments of pesticides containing surfactants and polymeric additives, which help the pesticides wet and adhere to plant surfaces. The surfactants reduce surface tension and force round drops to flatten, helping them cover more surface area on a sprayed plant's leaves. The polymeric additives reduce viscosity – liquid resistance – making the pesticide flow easier. Polymeric additives also keep the drops from bouncing off plant surfaces.

"Each additive is designed to improve the characteristics of the main drops," Corvalan said. "But there is a side effect."

When both additives are present in a pesticide, the surfactant pushes more liquid toward the filament. The reduced viscosity allows liquid to flow more easily in that direction, resulting in a well-defined satellite drop forming in the filament.

"When you put both additives together, there is a synergistic effect. The force induced by the surfactant that was opposed by viscosity is no longer so strongly opposed, and this combined effect can result in the formation of satellite droplets," Corvalan said.

Drifting of agricultural pesticides not only increases waste and cost for farmers but also can cause health, environmental and property damage, according to the U.S. Environmental Protection Agency.

The results show that carefully modulating the strength, concentration or ratio of surfactants to polymer additives can mitigate or eliminate the formation of unwanted satellite droplets.

Corvalan is now transferring the results obtained from agricultural research into food processing and rocket propulsion work. He said drop size uniformity is as important for fuels sprayed into rocket combustion chambers as for the production of food emulsions.

You May Also Like