“The ability to irrigate can help to lessen the risk involved in growing a crop like corn that needs water for maximum yield,” says Clint Tindall, who farms with his father, Butch, in northeast Mississippi. “And it can make a big difference in cotton, too — last year, on one of our farms we got 1.6 bales non-irrigated and 2.25 bales with irrigation. Crop insurance just isn’t that practical for many farms in this area. So, irrigation is our form of crop insurance.

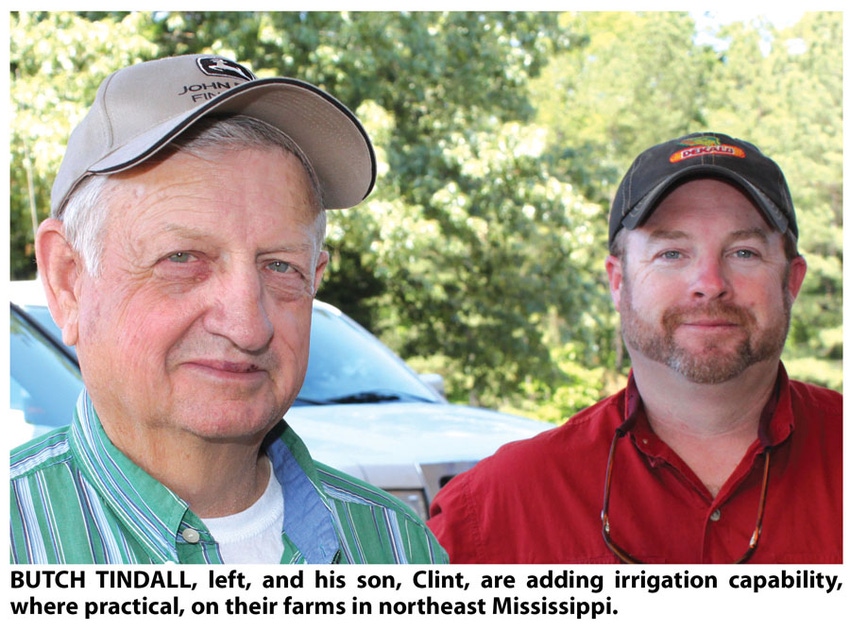

While waiting for fields to dry after a 2-inch rain earlier in the week, on a coolish late April morning Clint Tindall and his father, Butch, sit in the sunshine at their shop in the hills of Webster County, Miss., talking about the contrasts of their farming lifetimes and the challenges of modern agriculture.

“I’m the third generation to farm here,” says Clint. “My grandfather, Howard, farmed here all his life, growing cotton, corn, and some cows. My father has farmed all his life, and I’ve been a part of farm life from childhood. I’m hoping my two sons will continue the tradition.”

Butch says: “Farming is all I’ve ever done, I became a part of the family operation in the early 1970s, and we farmed together until 1995, when we split the operation. We had around 2,000 acres by then, growing cotton.”

“1995 was the year we all remember as The Worm Year — and it put a lot of farmers out of the cotton business. But we were able to get through it, and since Clint came back to the farm, we’ve been expanding and making improvements in our operations.”

After Clint earned his agricultural economics degree at Mississippi State University, he came back to the farm in 1997 and worked as a farm employee for his father until 1999, when he joined the operation.

“In one year, we went from 700 acres to 1,700 acres, all cotton,” he says. “We’ve continued expanding and now farm 2,700 acres in Webster County and adjoining Calhoun County, most of it rented.”

Queried about field numbers, he laughs: “I don’t really know how many fields we have — at least a hundred, maybe as many as 150, in all different sizes.

In 2008, they started diversifying and added corn and soybeans. But says Clint, “Our crops in any given year depend on what we think offers the best income prospects and what we need to do in terms of rotation.

“We really like growing both cotton and corn, and we’re trying to do all we can to push yields for those crops. We’ve started some irrigation projects, and will continue to add watering capability where it’s feasible.

“Right now, we can furrow irrigate 300 acres with water from two holding ponds, one 20 acres and the other about 10 acres. Center pivots just don’t pencil out for us — you have to go down several feet or more for water, and you need a big pump, which is expensive. Then, you’ve got the cost of the pivot.

“So, the more economical route for us is to take marginal land out of production to build holding ponds, put in relift pumps, and irrigate from polypipe.

“We try to be as conscientious as possible with our water use, and the water in the ponds has been adequate for our needs, combined with some timely rains.”

They bought a John Deere 9420 tractor and a dirt pan to use in building ponds, Clint says, and to scrape down some of the high spots and improve the grade in fields they plan to irrigate. They’re also working with NRCS on tailwater recovery systems.

'Irrigation is our crop insurance'

“The ability to irrigate can help to lessen the risk involved in growing a crop like corn that needs water for maximum yield,” Clint says. “And it can make a big difference in cotton, too — last year, on one of our farms we got 1.6 bales non-irrigated and 2.25 bales with irrigation.

“Crop insurance just isn’t that practical for farms in this area. You can pour your heart and soul into a crop, and with production costs as high as they are, a crop failure can take you down in a hurry. So, irrigation is our form of crop insurance.

“Irrigating is still a learning experience for us, but we’ve been pleased with results and will continue to expand our irrigation potential.”

In 2011, the Tindalls grew only cotton, but this year are adding corn back into the mix for the rotation benefit and to help with nematodes and to try and hold off glyphosate-resistant weeds.

“Thus far, we’ve only had resistant marestail,” Clint says, “but there has been some resistant pigweed in neighboring Chickasaw County, and we want to do all we can to keep it from getting a foothold on our land. Our burndown program the last three years has been with 2,4-D, and that has worked well; we’ve had only a few marestail escapes.”

Their crop plan this year is for 1,700 acres of cotton and 1,000 of corn.

For cotton, Clint says, “We like Deltapine 1133-B2RF on our stronger ground. Last year, some of our dryland picked 2.3 to 3 bales. On some of our irrigated fields, where we watered twice, we got 3.1 bales, which is excellent.

“We put Deltapine 1137-B2RF on our more marginal land and it did really well — we had some fields yielding in the 2.5 bale range. On our thinner, tougher ground, we planted Deltapine 1048 B2RF, and it did well also, with yields in the 2.25 to 2.5 bale range in places. We’ve been very pleased with the performance of all these varieties.”

Last year’s purchase of a CaseIH 625 module builder picker made a tremendous difference in the efficiency of their harvesting operations, he says.

“It was a like-new 2008 machine that we bought from Hood Equipment, and aside from the speed and efficiency, a big advantage has been in freeing our people up to do other things. With our previous operation, we were running four 4-row pickers and the associated boll buggies and module builders. It took a lot of people just to fill the seats and keep things moving.

“Now, we no longer need all that extra equipment — just one man to tarp the modules. In addition to the labor savings, there’s a lot of $4 diesel we don’t burn by eliminating all that extra machinery. We’re so pleased with it, we’re going to take a look at adding another one.”

They will keep a couple of the 4-row pickers as insurance for the very wet fall that may come along, Clint says. “Fully loaded, the new picker weighs about 30 tons and it would bog down in wet fields.”

Their cotton is ginned at Calhoun Gin at Calhoun City and at Doolittle Gin at Cadaretta. He says they hold out a bale per acre to market themselves and market the rest through Staplcotn and V&M Cotton Company.

“We’re really fortunate that our insect problems are light compared to the Delta. Last year, plant bugs were very light, and some fields weren’t sprayed at all. We did spray a few cotton fields where the plant bugs were moving out of corn.”

Wherever possible, Clint says, their production is no-till. “We’ve been doing some breaking on fields where we’re changing to 12-row.”

Corn variety choices

Corn varieties “come and go so quickly,” he says, that “we won’t be growing a single variety this year that we grew two years ago. We’ll be planting seven different varieties to match soil types, for ‘insurance’ against a variety failure, and to spread out harvest. Some of the seed will be treated with Avicta for root knot nematode suppression.”

Varieties this year are DEKALB 6469, 6805, 6697, and 6694 as the refuge variety; Northrup King N68B-3111 and N77P-3111; and Dynagro 56PV10. “We based these choices on field trial data for our area and soil types, and our past experience with these companies’ products.

“As we add irrigation and can increase plant populations, we’re hoping we can consistently get 150-175 bushels.”

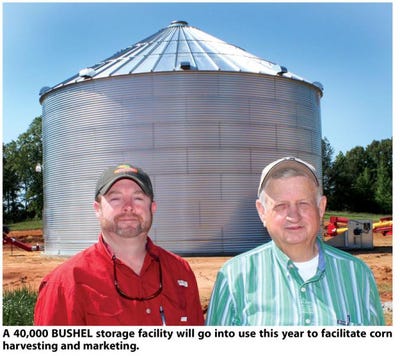

They’ve just added a new on-farm storage bin with 45,000 bushels capacity. Most of their corn is marketed through Gavilon Grain LLC at Rosedale, Miss.

“We’re changing over to 12-row planting this year,” Clint says, “and are rehipping land that was 8-row. This has allowed us to go from running five tractors to only one, another big savings of diesel fuel.

“We have both red and green equipment. Our CaseIH MX230 and MX240 tractors have Trimble auto-steer systems. We also have CaseIH MX110, MX7130, and MX7220 tractors and John Deere 7230, 8100, and 9420 tractors.

“We don’t have highboy sprayer; rather, we use spray rigs on our high clearance tractors. This is a more versatile arrangement for us, since the tractors can be used for other farm purposes, while the highboy is a one-use machine.”

They don’t presently have a combine, but will buy one this year — “just whatever is the best deal,” he says.

They soil test every year and make variable rate applications of dry fertilizer, based on Veris points.

“With our particular blends, it has been about as cheap to use commercial fertilizer as poultry litter,” Clint says. “But we want to try some litter to build organic matter where we cut down spots in fields to improve grade and facilitate irrigation.

“On fields new to irrigation, our plan will be to plant wheat, then double crop cotton, and plant corn the next year. This would give us three crops on the field, with two being heavy residue crops in two years.”

The Tindalls have six full-time employees and two drivers for the two 18-wheel rigs they operate for year-round contract hauling of grain and fertilizer.

Active in the Mississippi Farm Bureau Federation, Clint currently is serving as chairman of its Cotton Committee and was previously chairman of the Young Farmer/Rancher Committee. He also serves on the board of the Calhoun County Farm Bureau and is a National Cotton Council alternate producer delegate.

His wife, Kristy, is a teacher at Calhoun City, and they have three children, Connor, Emma, and Baylor.

Riding through the countryside, Butch Tindall reminisces: “Wouldn’t it be interesting if farmers from my father’s generation could come back and see how things are done today, how different they are from the mules and hand-picked cotton of their day?

“I was just a kid, but I remember the transition from mules and hand-picking, the battles with boll weevils, and the bermudagrass we fought tooth and nail.

“Just think how amazed those old-timer farmers would be at Roundup Ready and Bt technology, to learn about eradication of the boll weevil, to see huge machines with GPS and auto-steer, and mechanical pickers with on-board module builders.”

He smiles: “We’ve got all these ways to make farming more efficient — but it seems that paying the bills is harder than ever. We used to say if we had a bad crop or two, we could ride it out for a couple of years and catch up. But with costs the way they are now, and going up all the time, losing a crop can be hard to overcome. Losing two could put you out of business.”

About the Author(s)

You May Also Like