“From the original grower meeting to a done deal took 11 days,” says Mississippi cotton grower Glenn Mast, one of the stockholders in a new $6.5 million cotton gin now under construction in east Mississippi near Brooksville. “We’ve been assured that the gin will be up and running by Sept. 16. We’re really bullish on cotton, and this facility is an indication of other growers’ belief in the future of the crop here.”

Eleven days — that’s all it took for a group of east Mississippi cotton growers to go from talking stage to a signed, sealed, and financed deal to build a spanking new $6.5 million state of the art cotton gin in Noxubee County.

Even more amazing, rather than having the facility completed for the 2013 crop, as they’d expected, they’ve been promised by equipment suppliers and contractors that it will be up and running in September to gin this year’s cotton crop.

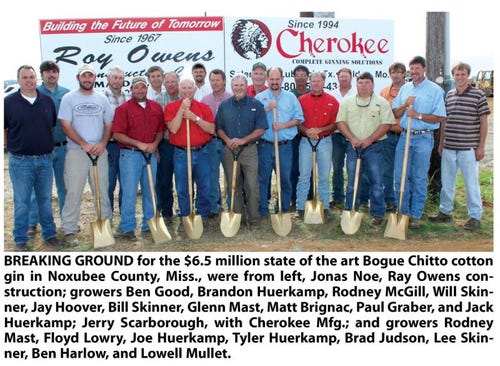

Groundbreaking ceremonies for Bogue Chitto Gin, located on the site of an old hog farrowing facility a few miles outside Brooksville, Miss., were recently held and construction is now going full speed for the plant that will feature two of the world’s largest gin stands, the Cherokee Magnum 244.

In the late 1800s, Noxubee County was the leading cotton producing county in Mississippi. Although the bulk of the state’s production later centered in the Delta areas along the Mississippi River, growers here in the Prairie region continue to be some of the state’s most progressive, with consistently high per acre production.

Last year, some of the state’s highest cotton yields were in this area.

Although growers here don’t have the advantage of shallow wells for irrigation like Delta producers, many operate center pivot systems from catchment ponds and reservoirs, and new systems continue to dot the landscape.

Increased cotton acreage in the region is an outgrowth of the experience of area growers that, with water, the mostly heavy black prairie soils will consistently produce high-yielding cotton, while soybean yields on the same ground can vary widely from year to year.

With the uptrend in acreage came a perceived need by growers for a gin that would be closer to their fields and would offer more efficient processing of their cotton.

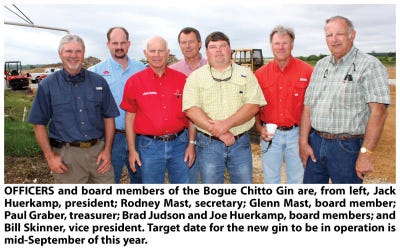

Stockholders in the gin represent a cross section of some of the best farmers around.

Valley Gin, once located in this area, shut down in 1982, says Jack Huerkamp, who is president of the new gin organization.

“The last year that gin operated, they were running four bales per hour. This new gin will be capable of ginning 60 bales per hour. It will rival 90 percent of the gins in the entire country, and is being built not only to handle present-day production, but with capacity to handle expected expansion of acreage.

“We’re going to have 20,000 acres of cotton this year within a 15-mile radius of this gin; that’s up from 5,000 acres just a couple of years ago. And we expect the availability of nearby ginning facilities will spur additional cotton plantings in the future.

“In addition to all the other benefits of ginning here, there will be significant amounts of money saved in hauling costs.”

Noxubee County officials who participated in the groundbreaking said the new gin will be a benefit to the county, not only with jobs, but by the turnover of money that cotton generates throughout the economy. “It’s a proven fact that cotton money turns over several times,” one of the officials said.

Growers bullish on cotton

Glenn Mast and his son, Rodney, are shareholders in the new gin; they farm 5,000 acres and have an equipment dealership in Lowndes County, Miss., near Columbus.

They’ve had soybeans in their crop lineup for years — but have dropped them altogether this year in favor of cotton. They’ve also exited their long-time catfish business and will use the 120 acres of ponds as reservoirs to feed center pivots.

“Some of us farmers had met the Tuesday before the Mid-South Farm and Gin Show to discuss the potential for building a gin for the 2013 season,” Glenn says.

“At the show, I talked with the Cherokee representatives about our interest and they told us they thought they could have a facility up and running for this year’s crop. Since we’d figured the best we could expect was fall 2013, we were excited about that.

“We came back from the show, had a meeting with our growers, who put $100,000 on the table as earnest money to order equipment. A week later, we had a stockholder agreement in place, had bylaws filed with the Secretary of State, and $1.6 million in grower commitments in order to secure financing for the balance. The Federal Land Bank did a fantastic job in helping us with financing the project.

“From the original grower meeting to a done deal took 11 days,” Glenn says. “We’ve been assured that the gin will be up and running by Sept. 16, and we have financial incentives built into the contract to encourage the suppliers and contractors to meet that target.

“We’re really bullish on cotton, and this facility is an indication of other growers’ belief in the future of the crop here.”

Rodney Mast says no new cotton gins have been built in this region in many years.

“Area farmers have been hauling cotton 50 miles to 100 miles to have it ginned. This new gin will not only save on transportation costs, but will give us a better product and put more money back in cotton farmers’ pockets. There has been 30 percent more cotton seed sold for planting in this area this year than last year, and with this new gin, I think we can expect that acreage will grow even more.

Jerry Scarborough, one of the owners of Cherokee Fabrication LLC at Salem, Ala., which will supply the gin equipment, says, “In my 50 years in the business, I’ve never seen a deal go together the way this one has. About as quick as I could get it out of my mouth that they’d need $100,000 earnest money, they had it.

“I went back to the office and told everyone I’d sold a new gin. ‘Who’s it for?’ they asked. ‘I don’t know,” I said. ‘What’s the gin name?” they asked. ‘I don’t know,’ I said, ‘but I’ve got five signed checks here and they’re ready to move.’ For something like this to come together in less than a two-week time span is unprecedented.

“The interest these growers have shown, and their willingness to work together to make the project happen, has been amazing,” Scarborough says.

“We seldom build new gins from the ground up — one a year, if we’re lucky. Most of our work is modifying or upgrading existing facilities, or doing repairs. Our most recent installation of our latest equipment was for the Kiech-Shauver-Miller Gin at Monette, Ark. We’re also in the process of building a new gin in Brazil on a 60,000-acre operation to replace an old one that’s only ginning 4 to 5 bales per hour.”

Changes in ginning technology have been impressive over the years, Scarborough says.

“A modern gin like this one will be can gin more cotton faster, more efficiently, and with better quality than earlier-generation machinery. This facility will have the largest gin stands in the industry — two 244 Magnums, each with 244 saws and each capable of ginning 30 bales per hour. The entire operation will have the latest digital controls and technology to constantly monitor all functions.”

It’s being designed to handle round modules from modern pickers with on-board module builders, he notes. Several growers associated with the gin have already purchased round bale pickers and others are planning to do so.

“The gin press can handle about 70 bales per hour, and there will be a 142-inch lint cleaner,” Scarborough says. “The facility will also include an 85,000 ton seed house, one of the biggest in Mississippi.

“When I started in the business in 1960,” he says, “there were 4,500 gins operating in the U.S. Now, there are only about 650, but the volume of cotton they gin is far more than that of all those earlier era gins combined.”

About the Author(s)

You May Also Like