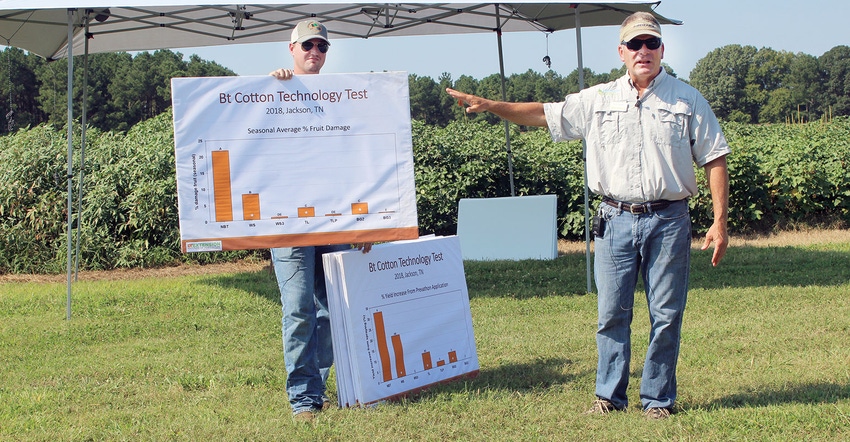

Dr. Scott Stewart, Extension entomologist, University of Tennessee, told growers attending the recent UT Cotton Tour Field Day that using diamides to control bollworms in varieties containing two Bt gene technologies saves yield.

His 2018 Bt management trials had twice the pressure that his current trials experienced. “I had season-long fruit damage on over 20 percent of those cotton trials last year, but at its peak, I had 30 to 40 percent boll damage, which caused significant yield loss,” says Stewart. “Some of the effectiveness of these technologies, like the original WideStrike technology and Bollgard II, are weakening and if you have any kind of sustained pest pressure, you’re going to have to pull the trigger on a spray.”

Stewart knows the low worm pressure this year has allowed Bollgard II to be more effective than last year, but his data confirms significant yield savings from applications of Prevathon when applications were necessary. “Even two applications of Prevathon on non-Bt cotton will make that cotton look really good, especially when those applications are timed correctly,” says Stewart. “It’s better to be a little early with those applications than late.”

Worms in Bollgard III?

There are rare examples where even the three-gene technologies like Bollgard III might require an application for bollworms, so every field should be scouted for the pest, especially when a field is under high pressure. “We saw some worms in our plots of Bollgard III this year, but when we tested the variety for the VIP trait, it wasn’t there,” says Stewart.

“We found out a bag of Bollgard II and Bollgard III had been flopped. This can happen in any farming operation. Also, there can be a few plants in a field of three-gene cotton that may not express the VIP trait.”

With the current price of cotton, growers are evaluating every input, but spraying the older Bt technologies for bollworms is just a fact of life right now. Diamides are Stewart’s recommended mode of action on two-Bt gene technology when needed because they provide good residual control. “Once you start using and tracking these products, you’ll really start to see long-term benefits,” says Stewart. “But keep in mind that worms may be under bloom tags, in a flower or boll, and they may not come out for six or seven days, so there is no such thing as an insecticide that provides perfect control.”

Towards the end of the season when residual control is less needed, Stewart thinks there is still an opportunity to use a pyrethroid insecticide tank-mixed with acephate. “This combination will provide decent control of bollworms for four to five days, and it’s also a good choice when you are trying to clean out your last plant bugs or stink bugs,” says Stewart. “The bollworm is the only pest we’re seeing a substantial problem with right now. The Bt technologies continue to work well on other caterpillar pests.”

Thresholds on two-gene Bt cotton is a point of contention with Stewart. A 20 percent egg threshold is being recommended by universities in the Mid-South for bollworm control. “I’ve seen situations where an egg threshold falls on its face. If you have a 10 to 15 percent egg threshold for two weeks, you are likely going to have to spray,” says Stewart. “You’ve got to use some professional judgment. It would be nice if we had a scouting method that would work across all technologies.”

Uniform scouting method

Stewart’s master’s degree student, Dawson Kerns, realizes people scout for worms differently. Some may be looking only at bloom tags, whereas others may check the entire plant. When they get calls for recommendations, it is difficult to make a confident decision when scouting methods vary.

As part of Kern’s research, he is mapping where worms and plant injury are being found. He wants to know what role Bt technologies are having on that damage. “Under certain circumstances, you have different levels of expression in different parts of the plant,” says Kerns. “On some of the Bt technologies, the worms may gravitate toward those lower expression fruiting structures. I would like to find a uniform scouting method that works across all Bt cotton technologies.”

Kerns is also trying to develop a resistance bioassay method that will predict how bollworms may survive in a field of Bt cotton. The current process is tedious and time-consuming. “We’d like to see a method that uses plant tissue. This might give us better insight about how well worms may be controlled when they are exposed to multiple Bt toxins at the same time,” says Kerns.

Stewart ended his tour stop with a word of warning about the industry using VIP technology in corn and then using the same VIP toxin in Bollgard III, WideStrike3, or TwinLink Plus cotton. “I just can’t get excited about it,” says Stewart. “I don’t want to select worms in corn with VIP technology, and then have them leave and go to cotton. Most data I’ve seen doesn’t show a significant benefit from that toxin being used in corn.”

About the Author(s)

You May Also Like