Cotton has had its ups and downs in the last few years. But that hasn’t stopped the winners of this year’s Cotton Foundation/Farm Press High Cotton awards from trying to produce the best and most environmentally-friendly crops they can.

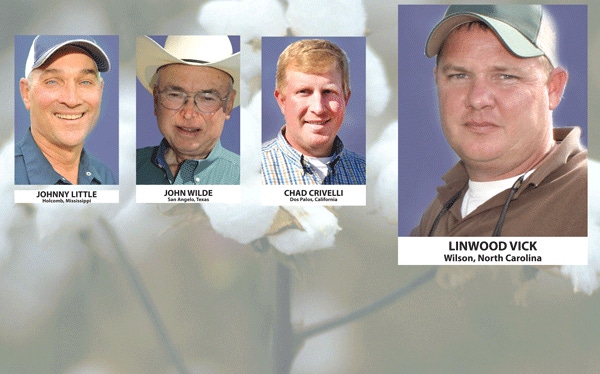

The 2013 winners — Linwood Vick, Wilson, N.C.; Johnny Little, Holcomb, Miss.; John Wilde, San Angelo, Texas; and Chad Crivelli, Dos Palos, Calif. — have continued the High Cotton Award traditions of growing good, profitable cotton in an environmentally friendly manner.

And they’ve done it despite a less than favorable price outlook, excessive moisture in some areas and drought conditions in others and rising input costs. For their efforts, they and their families will be honored at the National Cotton Council’s Beltwide Cotton Conferences in San Antonio, Jan. 7-10.

“The 2013 High Cotton Award winners are some of the most efficient cotton producers in the nation,” said Greg Frey, vice-president at Penton Media and publisher of the Southeast, Delta, Southwest and Western Farm Presses. “But they also do their utmost to protect the land, air and water. They represent the very best in environmental stewardship.”

Each of the 2013 winners and their spouses receive an expense-paid trip to the Beltwide Cotton Conferences. They will be joined by family members and friends at a breakfast honoring them and their achievements on Jan. 9.

The High Cotton Awards are presented annually by Farm Press Publications through a grant to The Cotton Foundation. Cosponsors of the 2013 awards are All-Tex Seed, Americot/NexGen, AMVAC, Arysta LifeScience, Deltapine, Dow AgroSciences, Helena Chemical Company, John Deere, MANA Crop Protection, Syngenta and U.S. Borax.

Southeast winner

Ironically, growing cotton was one of Linwood Vick’s least favorite things when this year’s Southeast winner returned to the family farm after graduating from the North Carolina State Agriculture Institute in 1997.

“We had a big problem with soil erosion,” Lyn says. “Early in the growing season especially, our conventional cotton was literally sandblasted by our fine, sandy soils. When Roundup Ready cotton came along, we switched to no-till cotton, soybeans, double-crop soybeans, and wheat.

“Our tobacco and sweet potatoes are grown with conventional-tillage, so going no-till on cotton and soybeans helped improve the tilth of our soil and helped with those erosion problems.”

He rotates his cotton with sweet potatoes, tobacco and soybeans. Having sweet potatoes and tobacco in the rotation is a bit unusual, but he says it has been a blessing in battling glyphosate-resistant pigweed.

The unusual cotton rotation also aids in suppression of nematodes. Most of their tobacco and sweet potato land is treated with Telone and Lorsban, so they are carrying out practices as a part of their normal farming operation that gives a side benefit of reducing nematode populations.

Labor-intensive crops

Both sweet potatoes and tobacco are labor-intensive crops, and Vick Farms is a pioneer in using legal, H-2A labor. “Having adequate labor on hand for these crops can be a big advantage in our cotton operation,” Lyn says. “If we get in a situation where we can’t get in a field with the right herbicide, we can always use some of our labor to clean up those fields.”

Each member of the Vick family speaks Spanish. The farm has 10 full-time employees, and all but two speak Spanish.

“It’s a tool that’s important in our farming operation,” he says. “Whether or not I’m fluent in Spanish, I don’t know, but I can explain to any of our H-2A workers what I want them to do and how I want them to do it. Lack of communication should never be an excuse on our farm for not getting things done right.”

Mid-South winner

Being “willing to try new things and think outside the box to address problems” has helped Johnny Little, this year’s High Cotton winner from the Mid-South, be successful.

Little farms 1,175 acres of cotton and 350 acres of corn near Holcomb in north central Mississippi. For many years, he farmed with his father, John Morgan “Buddy” Little, who passed away at the age of 89 last spring

Declining cotton prices have had an impact throughout the Delta states, forcing growers to make adjustments to their production and marketing strategies. For Little that includes cutting back on cotton acres for more corn and putting in three grain bins, as grain prices continue to show strength.

But that doesn’t mean completely giving up on cotton. “I’ll always have cotton in the mix because cotton has always paid our bills.”

His operation is based on maximizing efficiency by keeping equipment in tip-top shape, making variable-rate applications, using no-till, following label instructions and recommendations from his consultant to the letter, and of course, hard work.

Cotton did surprisingly well for Little in 2012, despite a very dry summer. Irrigation and appropriate variety choices for dryland and irrigated fields are critical to making consistently good yields, he says.

Stewardship is synonymous with efficiency on the Little farm, and there’s no better example of this relationship than his commitment to no-till. Little first adopted the practice 10 years ago, and it has proven to reduce labor requirements significantly while enriching the soil’s tilth.

Precision systems

Little credits employee Josh Coffman for helping with the transition to precision agriculture systems. With Coffman’s help, Little has added GPS guidance on all tractors and yield monitors on his combine and cotton picker, and they’ve seen the benefits.

They’ve also adopted variable-rate fertilizer applications.

He believes the best benefit of variable rate versus blanket applications is the ability to increase productivity on his best soil types, rather than pushing yield on tougher ground.

Southwest winner

Like many Texas and Oklahoma growers, John Wilde, this year’s Southwest High Cotton winner, is still battling the lingering effects of the Drought of 2011.

Wilde produced more than four bales per acre on a field of drip-irrigated cotton near Miles, Texas, in 2012. About 800 acres of the Wilde cotton operation, centered in San Angelo and including farms to the east near Miles and back west near St. Lawrence, are drip-irrigated.

“Water is the key,” says Wilde, who is doing all he knows how to make every drop count.

Subsurface drip irrigation helps, as do reduced-tillage and rotation and subsoiling between the drip tapes. He also uses furrow diking to reduce runoff and has installed wildlife vegetation strips on CRP land.

He is committed to producing the best yields possible. He’s also devoted to conserving soil and water so the land that has been in the family — some for as long as 100 years — will pass on to his heirs in better condition than when he took it over.

Wilde is also adamant about finding something to control root rot, the most economically devastating cotton disease in his area. He has a long-term commitment to helping Texas AgriLife Research and Extension discover a management option for the disease.

Eight years ago, Wilde recognized the importance of increasing irrigation efficiency when they installed the first subsurface drip irrigation on 38 acres. Now they have 800 acres of drip-irrigated cotton. “We started small,” he says.

Drip irrigation pioneers

“We had some of the first drip irrigation in the area, and we saw the benefits.”

They’ve reduced tillage over the past few years as well. “We’re not quite to minimum-till,” he says, “but we have reduced-tillage.”

They also use reclaimed wastewater to irrigate some fields. “We filter it and put it through the drip irrigation system.”

His sons, Doug and Matt, work with him as partners on the farm. “It’s what they want to do,” he says. “And where else but a farm can you have the opportunity for parents to work so closely with their children?”

Far West winner

While many cotton producers fight drought, root rot and other agronomic woes, this year’s High Cotton winner from the Far West is also fighting to present the environmentally-sustainable side of the cotton industry to the public.

Chad Crivelli of Dos Palos, Calif., takes advantage of every opportunity to improve the environmental footprint of his family’s cotton operation in Merced County and to show that cotton growers are being proactive.

Since 1999, the Crivellis have been part of the San Joaquin Valley Sustainable Cotton Project, which not only works with growers to develop new, reduced cost and low environmental impact cotton-growing techniques, but also to extol the virtues of sustainable farming practices to those who buy SJV cotton.

“Chad has been an advocate and a public face of the cotton-growing community to hundreds of consumers, educators and fashion industry representatives who have toured valley cotton fields in the past decade,” says Marcia Gibbs, director of the sustainable cotton project.

Pete Goodell, University of California IPM advisor, says, “Chad meets with people during field trips to share the story about sustainable cotton. He is a great spokesperson for urban folks who don’t understand what’s going on in cotton industry. He represents the cotton industry incredibly well.”

“Chad is a very progressive farmer,” says Matt Whittaker, Helena Chemical Co. pest control adviser at Merced, Calif. “He stays up-to-date on new technologies, and practices solid IPM strategies and sound fertility programs. He is very innovative and fast to act on opportunities.”

Next year if prices increase, he could go up to 700 acres of cotton on his family’s 1,800-acre operation. Their other crops in 2012 included processing tomatoes, alfalfa, corn, melons, vegetables and 40 acres of permanent pomegranates. In the past, he has also grown chili, small grains, organic Pima cotton and hybrid Hazera cotton.

When cotton prices fall, Chad considers himself fortunate to have economic alternatives.

“Twenty years, ago 90 percent of the land around here was cotton after cotton,” says Bill. “We used to be happy with 3-bale, maybe 3-1/2 bale cotton. Now, we shoot for four bales, and a lot of that is due to the good rotation programs we currently use.”

EDITOR’S NOTE — Over the next several days this website will have more in-depth looks at the production practices of each of these four growers. The first article, featuring the Southeast’s Linwood Vick, will appear tomorrow.

About the Author(s)

You May Also Like