November 19, 2013

It is essential to continue to manage your corn and soybeans once they’ve left the field by keeping the grain in good condition once it’s loaded into bins. Proper management begins with the loading of the grain into the bin, followed by managing temperature and moisture content of the grain mass and having a regular observation program to detect development of problems before they get out of hand.

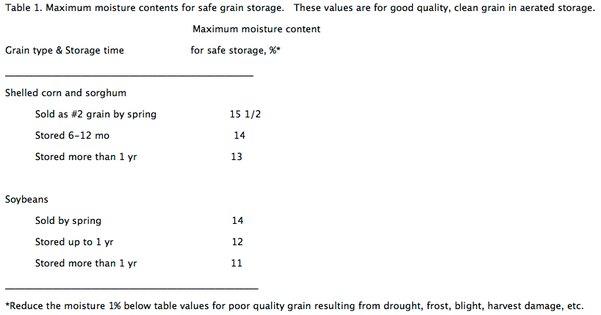

Recommended, safe-grain moisture contents for storage vary with type of grain and projected length of storage (Table 1).

Good grain storage management should have started at the time of filling the grain storage structure, which is usually a cylindrical bin of various sizes. Grain should have been cleaned as it was being off-loaded from grain carts and loaded into the bin. For ease of management practices such as controlling temperature and moisture content of the grain using aeration fans, the grain should be free of dirt, weed seeds, fines and chaff. Not cleaning these materials out of the grain mass can result disruptions of air flow through the entire mass. Areas of heavy deposition of these materials can be so dense that moisture and temperature cannot be altered. Coring the grain mass occasionally while it is being filled can reduce the amount of fines, etc. that accumulate in the center of the grain mass.

Like what you're reading? Subscribe to CSD Extra and get the latest news right to your inbox!

One error that many grain managers allow to occur after corn and soybeans have been loaded into a bin is leaving a peak of grain in the head space area and/or over-filling a bin to the point that there is no room to work in the head space area. One should be able to enter the head space area of a filled bin to level the grain to a common depth across the entire diameter of the bin. Peaks on top of the grain mass are difficult to manage with aeration. Air, like water, will travel the path of least resistance. Air will more quickly exit a grain mass through the lowest edges of peaked grain leaving the center of the peaked grain not aerated.

Airflow and temperature adjustments

Aeration fans should be started as soon as the bin floor is covered with grain and operated continuously until the grain is dry or the average air temperature is below 35° F for extended periods. Leave all roof hatches open to provide a large air exhaust opening, approximately 1 sq. ft. for each 1,000 cubic feet per minute of air delivered to the bin.

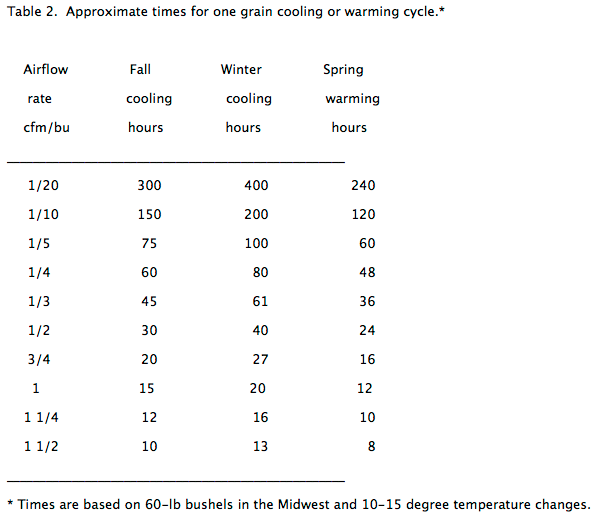

Adjusting the temperature of grain in a filled bin should be done in steps. The movement of a temperature front (zone) completely through the grain is one cooling or warming cycle. Each time an adjustment is made; one must run aeration fans continuously until the zone moves completely through the grain before shutting down the system. Failure to do so can lead to major problems in the grain mass wherever the front was allowed to stop. How long that takes varies with the number and sizes (airflow rates) of aeration fans attached to a bin, as shown in Table 2.

Grain drying or rewetting is usually insignificant during grain aeration. Because the cooling (or warming) front moves through the grain about 50 times faster than a drying or wetting front, only a small fraction of the grain is rewetted during an aeration cycle, even with high humidity. As a precaution, operate the aeration fan only long enough to accomplish the grain cooling or warming cycle. This is particularly important with higher capacity aeration fans.

When the daily average temperature drops below 35° F, cool the grain to a uniform temperature and turn the fan off. If moldy odors are detected or the grain starts to heat, turn the fan on until the conditions are corrected.

After cooling is completed, close the roof hatches and cover fan inlets to prevent migrating air from adding moisture to the grain.

If grain has been dried correctly for the storage period intended, problems with grain condition usually result from: 1) Improper grain cooling; 2) Inadequate observation of the stored grain for early detection of developing problems; 3) Poor initial grain quality; and 4) Improper insect control. Each of these problems can be minimized with good management.

Remember, working around flowing grain and grain in storage can be very dangerous. Follow safety rules at all times while working in or around grain bins.

For more information about managing dry grain in on-farm storage bins see factsheets from Purdue and Ohio State:

Managing Dry Grain in Storage (Purdue University)

Natural Air Grain Drying in Ohio FactSheet AEX-202-06 (The Ohio State University)

You might also like:

No-till acceptance disappointing

You May Also Like