November 3, 2010

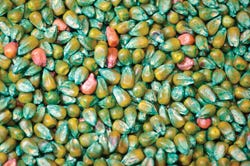

Managing your corn refuge requirements could become a whole lot easier, as the marketplace eagerly anticipates refuge-in-a-bag products that will blend traited corn seed with non-traited seed that meets refuge requirements in a single package.

Managing your corn refuge requirements could become a whole lot easier, as the marketplace eagerly anticipates refuge-in-a-bag products that will blend traited corn seed with non-traited seed that meets refuge requirements in a single package.

The EPA is slated to convene a Scientific Advisory Panel to review several product submissions related to the refuge-in-a-bag concept beginning late this year. And pending regulatory approval, companies expect to introduce various refuge-in-a-bag products for the 2012 planting season. Pioneer’s first in-the-bag refuge product for corn rootworm was approved in 2010 and will be available for the 2011 planting season.

Simple concept, difficult execution

It sounds like an easy concept: Blend non-traited corn seed with traited seed to establish a stand that contains enough susceptible corn plants to help prevent corn pests from developing resistance to the trait. However, getting to the point that a refuge could be incorporated into a single corn seed unit was a complex task. It required the underlying science to be established, along with a significant amount of research to determine the right mix producers could plant confidently to ensure they wouldn’t pay a yield penalty.

When the first Bt products hit the market in 1996, that single gene required the establishment of a 20% refuge to help ensure that resistance would not occur.

“Early corn refuge requirements did not consider refuge in a bag in part due to early research on cotton pests and how they might move,” says Lindsey Flexner, DuPont research fellow, Trait Characterization and Development. “But as we looked at various models and the corn pest biology, the early assumptions about cotton pests did not always hold true. It moved us into thinking that blended refuge actually fit into the biology of various corn pests.”

But at the 80-20 refuge requirement in the Corn Belt, a blended product didn’t make economic sense. Separate refuges could be managed differently to control pests, something that would be much more difficult — if not impossible — if 20% of the refuge seed were dispersed throughout the field.

Seed companies began to build their case for a reduced refuge. “Approval of refuge reduction was a big event,” says Robb Fraley, chief technology officer for Monsanto. “The 5% structured refuge allowed us to work at further developing the in-the-bag refuge concept.”

Armed with a reduced refuge requirement, companies began to research whether the 5% structured refuge could be incorporated into the bag without any yield penalty.

“We didn’t just pull the 5% number out of a hat,” says Bill Hendrix, biology team leader, insect traits and seed treatment at Dow AgroSciences. “We worked to validate that a 5% refuge incorporated into a single bag was an effective refuge management tool and provided sufficient insect protection.”

The key to the 5% refuge requirement is the multiple modes of action that today’s and future trait stacks will deliver. “Unless there are two distinct modes of action, the 5% refuge requirement would likely not be attainable,” says Grant Ozipko, traits marketing manager for Syngenta Seeds. “And our surveys show that producers begin to lose interest in a blended product once the refuge amount moves above 5%. That is largely due to the increased amount of unprotected seed.”

Moving toward a refuge-in-a-bag product has also required a significant advancement in machinery and manufacturing. “We have reconfigured existing seed manufacturing processes to develop a unique process that accurately put the required amount of refuge seed in each batch or bag,” Fraley says. “This is a precise technology, so we don’t want parts of the field to have refuge. We want the refuge interspersed throughout the entire field.”

Pioneer’s refuge products have a 10% blended approval. “Placing refuge more effectively throughout the field enables random mating for corn rootworm,” Flexner says. “We have worked with the EPA to show that our blended rootworm refuge approach used in the Optimum AcreMax 1 and Optimum AcreMax RW products works due to its compatibility with rootworm biology and the characteristics of the Herculex RW trait. It combines our understanding of the pest biology with the ability to reduce refuge requirements.”

And even more important is that the refuge seed used in the end product looks, and acts, the same as the traited seed. “In our research, growers have asked for the refuge hybrids to be nearly indistinguishable from the traited hybrids,” says Casey Onstot, traits marketing manager for Dow AgroSciences. “Therefore, we have set our standards appropriately to be able to deliver a product that meets growers’ expectations when it comes to seed size, plant height, relative maturity, drydown and other key characteristics.”

It has been several years in the works, but researchers are confident that the products submitted to the EPA will provide producers with a single-source solution for meeting refuge requirements while providing optimum yields.

Easy to use

“Integrating refuge has been a welcomed advancement,” says Laura Higgins, research program leader for Pioneer. “As products are approved, it will be a big win for growers because it is simple, efficient, and makes life easier during planting.”

What may also be a key selling point to regulators is that it will ensure that refuge requirements are being met, experts say. “Compliance can be a critical factor in how long these traits last,” Flexner says. “If we are able to ensure putting refuge on every acre where it belongs, in the long run we can prolong durability of the trait.”

The changing refuge requirements created some confusion among growers as to which refuge to plant for the products they were using. “A simpler approach that harmonizes refuge deployment [like integrated refuge] resonates with growers,” Higgins says.

And as producers move toward larger and larger planters, the ability to plant a single product on every acre, without the added management decisions associated with a structured refuge, will mean fewer decisions during planting time.

“The single-product approach allows producers to plant as they did before the advent of Bt products,” says Holly Butka, corn product marketing manager for Monsanto. “There is a high level of interest as producers look to be more efficient during planting time.”

About the Author(s)

You May Also Like