August 17, 2022

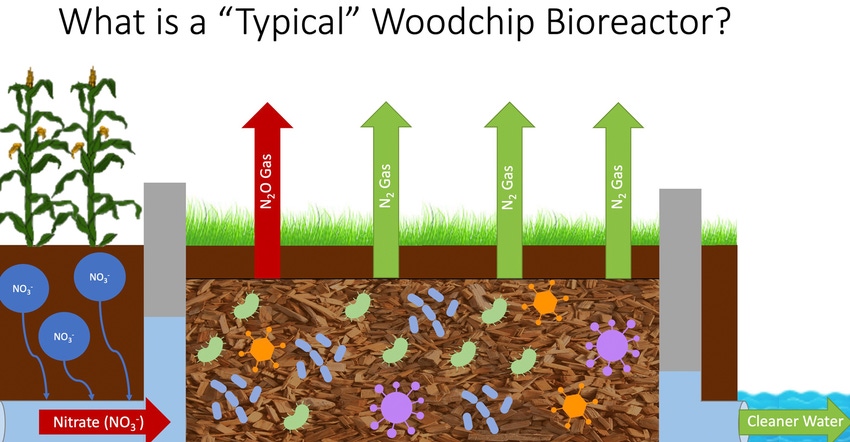

Denitrification bioreactors deployed across Iowa are edge-of-field structures proven to remove nitrate from subsurface drainage water exiting farm fields. The typical configuration of these belowground structures employs woodchips to filter nutrients from water leaving fields. Naturally occurring beneficial bacteria in the woodchip bed consume nitrate and convert it primarily into nitrogen gas. This results in cleaner water leaving the bioreactor.

“We have a good understanding of what happens as water moves through the bioreactor, and through sampling at different points along the flow, we can map how nitrate is converted and how well the bioreactor ‘cleans’ the water of nitrate,” says Lindsey Hartfiel, an Iowa State University doctoral student working under the direction of Michelle Soupir, a professor in the ISU Department of Agricultural and Biosystems Engineering. “However, we are just scratching the surface of exploring ways to get more utility out of bioreactors and potentially extend the service life of the wood chip beds.”

In a recent Iowa Learning Farms webinar, Hartfiel discussed two ideas that have helped frame research questions to address the goals of extending utility and service life of bioreactors.

Water volume affects results

The volume of subsurface drainage water flowing through bioreactors is closely related to the crop cycles within the fields. In general, flow is high in the spring and tends to stop in midsummer. One field study sample showed flow beginning in March or April and ceasing in July during two successive years. Hartfiel noted that as the growing season progresses, mature plants in the field consume greater quantities of water, effectively eliminating drainage flow.

“Since bioreactors only work when water is flowing, it is common that there is no denitrification occurring for six or seven months of each year,” Hartfiel says.

Woodchips affect denitrification

The second concept Hartfiel mentioned stems from the hypothesis that when bioreactor wood chips are subjected to fluctuations in saturation levels, they tend to break down more rapidly. Following this theory, extending the period that water is flowing through the bioreactor should help maintain saturation levels, and, in turn, could prove to extend the service life of the wood chip bed.

“We believe extending the period of regular saturation will provide data and insights that could further the effective life of bioreactors,” Hartfiel continue. “In addition, there are some less favorable processes that occur in underutilized bioreactors that could be mitigated by increased periods of flow to the bioreactor.”

In normal bioreactor operation, as nitrate is completely reduced by the microbial processes in the wood chip beds, the bacteria will begin to break down sulfate (SO42-), a process that has been linked to methylmercury production. Methylmercury is a highly toxic organic compound and human health hazard that can bioaccumulate in the environment and through the food web, exposing higher-order consumers to mercury poisoning. According to the U.S. EPA, methylmercury is the form of mercury people in the United States encounter most frequently.

One practice that can supplement inflow to bioreactors is the use of pump technology to feed irrigation or surface water into the subsurface structures. Water from nearby creeks and streams, or retained in surface edge-of-field structures such as wetlands, multipurpose oxbows, ponds and water and sediment control basins, often contains significant nitrate levels. This water can be pumped into bioreactors during periods of low subsurface drainage flow to increase environmental denitrification and maintain saturation.

Pumped bioreactor case study

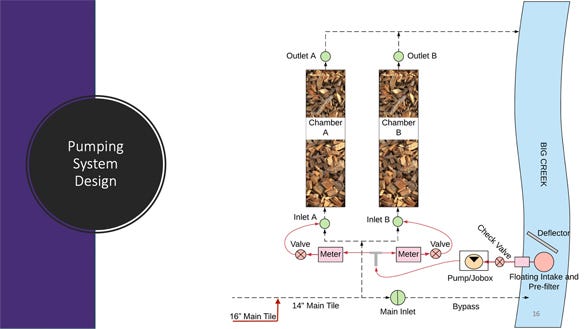

To study these and multiple other scientific pursuits, a pumping system has been implemented in conjunction with an existing two-chamber bioreactor adjacent to Big Creek in central Iowa. Each chamber is approximately 34 by 120 feet, and the system is fed by a 14-inch tile line. Water from Big Creek has been tested to have nitrate levels exceeding safe drinking water limits. The water is drawn from the creek and fed into the bioreactor inlets to supplement flow volume from the drainage tile.

“The project is in its early stages, and there is still a lot to learn and explore as we measure the flow of surface water into the bioreactor, and examine water samples from the multiple test wells situated in each chamber,” Hartfiel says. “The case study involves researchers in multiple departments and disciplines collaborating to not only implement the pumping system, but to continuously explore new and different perspectives and experiments that can increase our collective knowledge about bioreactors.”

To view Hartfiel’s Iowa Learning Farms webinar, or learn more about conservation practices and research, visit iowalearningfarms.org.

Staudt is director of Water Rocks! and a conservation outreach specialist with Iowa Learning Farms.

You May Also Like