Soil compaction is invisible, but its effects are clear to see: cloddy soil, delayed crop emergence, restricted root growth, stunted plants, low water infiltration, poor nutrient uptake and lost yield.And reduced production isn’t the only penalty. Soil compaction also harms the environment, leading to more runoff and soil erosion.The threat of soil compaction is far greater today than in the past because of the increasing size and weight of farm equipment. Although the risk of new compaction is low when the soil is very dry – as it is in much of the Corn Belt – existing compaction makes crops more vulnerable to damage by drought.

March 27, 2013

What’s the best way to manage soil compaction? Prevent it from happening in the first place, says Sjoerd Duiker, a Pennsylvania State University soil scientist. “Instead of looking for solutions to get rid of compaction, we’re trying to promote practices that avoid compaction from the beginning.”

How well do you understand the causes of soil compaction – and how to avoid it? Test your knowledge below, then take our quiz to assess your soil compaction risk.

1. Topsoil and subsoil compaction have different causes.

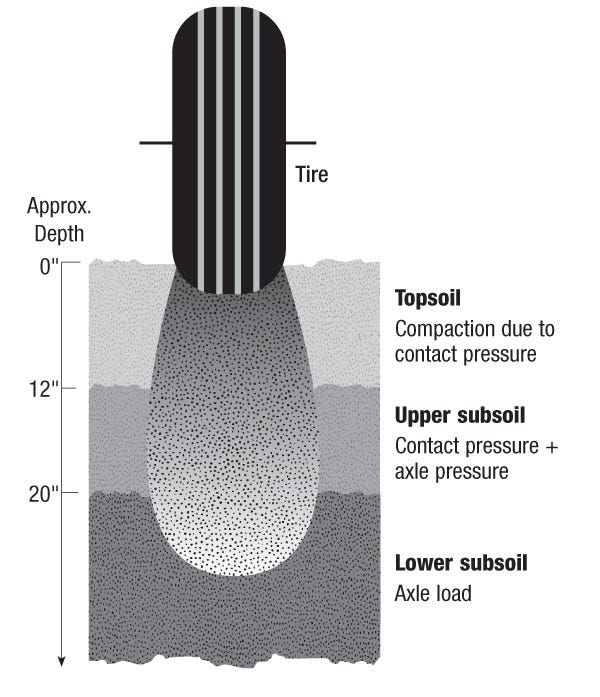

Answer: True. Compaction in the top 12 in. of soil is due to ground contact pressure, says Penn State’s Duiker. That’s the force exerted by a tire or track on the soil surface, expressed in pounds per square inch, or psi.

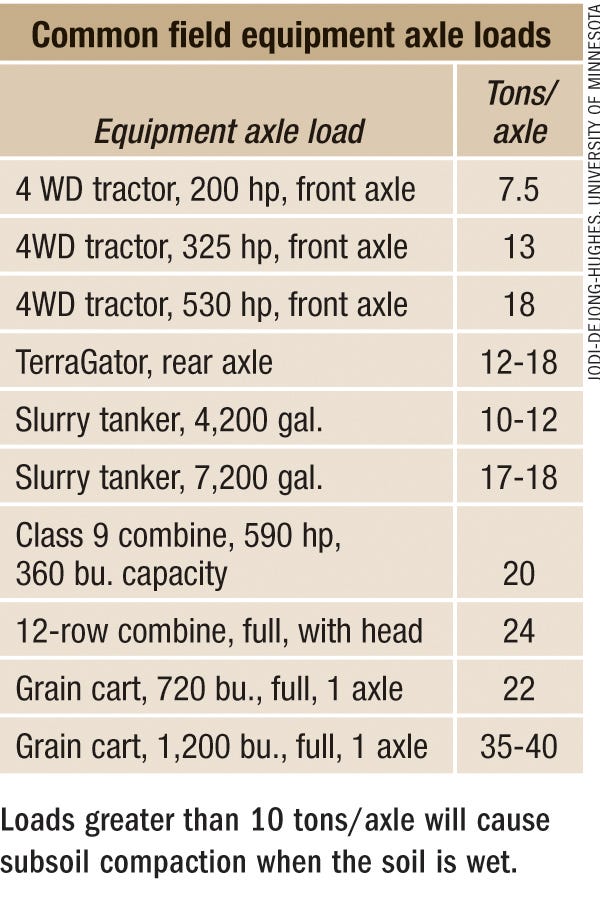

Compaction in the upper part of the subsoil, from about 12 to 20 in., is caused by a combination of ground contact pressure and axle load.

Compaction in the lower subsoil is caused by high axle loads when the soil is wet. In soils with a hardpan, Duiker adds, compaction from heavy axle loads will be concentrated above the restricted layer. Plowing with a tractor wheel in the furrow is another cause of deep compaction, says Jodi DeJong-Hughes, University of Minnesota Extension educator-crops.

2. Topsoil and subsoil compaction have different effects on yield.

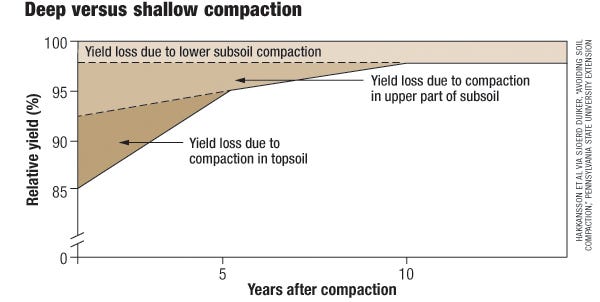

Answer: True. “Surface compaction causes large yield reductions that are relatively short-lived,” Duiker says. “Deep compaction causes less yield reduction, but it is very long lasting (c).”

Research at Ohio State University found that corn and soybean yield losses persisted for more than a decade after the soil was compacted, says Randall Reeder Ohio State University ag engineer emeritus, even though no further compaction occurred. Average yields (a) were about 10% lower than on non-compacted soil. The effects on topsoil compaction gradually abated, but compaction in the subsoil (b) continued to reduce yields, even after 12 years.

“Lower subsoil compaction is, practically speaking, permanent,” Duiker says, “and should therefore be avoided by all means, whereas topsoil compaction and upper subsoil compaction are temporary and should be limited as much as possible.”

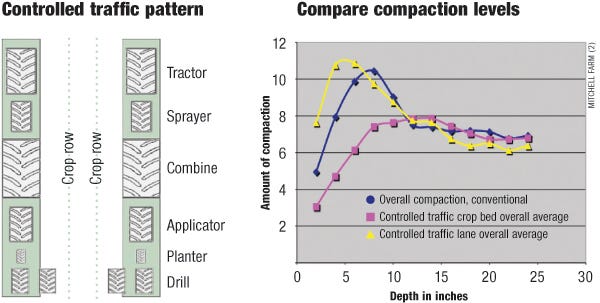

Left: Controlled traffic matches implement widths to align all field traffic into lanes, limiting compaction to just 17%, compared to 85-100% of a field compacted in conventional operations. Right: A controlled-traffic field has much lower overall soil compaction (pink line) than a conventionally farmed field (blue line), as measured by soil penetrometer resistance. The traffic lanes, (yellow line) contain the compaction to spare the growing zones.

An internal study from 1988 to 2002 found that the effects of compaction in the topsoil and upper part of the subsoil abate after five to 10 years if there is no further compaction. But deep subsoil compaction persists.

3. Freeze-thaw cycles alleviate soil compaction caused by machinery.

Answer: False. “It’s a myth that the freeze-thaw cycle solves compaction,” Reeder says. The effects of freezing and thawing are confined to the top few inches of soil. In the northern latitudes, the ground typically stays frozen 20-40 in. deep all winter, so you get only one cycle. In the eastern and southern parts of the Farm Belt, there are repeated freeze and thaw cycles, but the ground seldom freezes more than a foot deep – not enough to resolve deep compaction.

In the Midwest, where many soils have a high content of expanding clay, wetting and drying cycles break up more soil compaction than freezing and thawing, says DeJong-Hughes. The 2012 drought caused fracturing and cracking in the upper 6-20 in. of soil, says Al-Kaisi. The drought also triggered other soil changes, he says, especially in tilled fields, such as crusting and deterioration of soil aggregates.

In soils that contain expanding 2:1 clay, wetting and drying cycles can fracture soil down to 2 ft. helping the soil recover from compaction.

4. Clay soils are more easily compacted than coarser soils.

Answer: False. Clay soils are no more vulnerable to compaction from traffic than lighter soils, Reeder says, contrary to earlier theories. However, soils with a high proportion of clay tend to have poor internal drainage and are apt to stay wet longer than coarse, sandy soils, Duiker says. And wet soils are easily compacted.

On all soil types, compaction increases soil bulk density, and past a certain level, restricts root growth, Duiker says. That level differs with soil texture. For example, the ideal bulk density for clay soils is smaller than for loamy or sandy soils, which have larger particles and bigger pore spaces, compared to fine-textured soils.

Penetration resistance is another way to measure the effects of soil compaction on root growth. Regardless of soil type, root growth begins to decrease with penetration resistance of 100 psi, and stops completely at 300 psi. Try to keep penetration resistance under 200, DeJong-Hughes says.

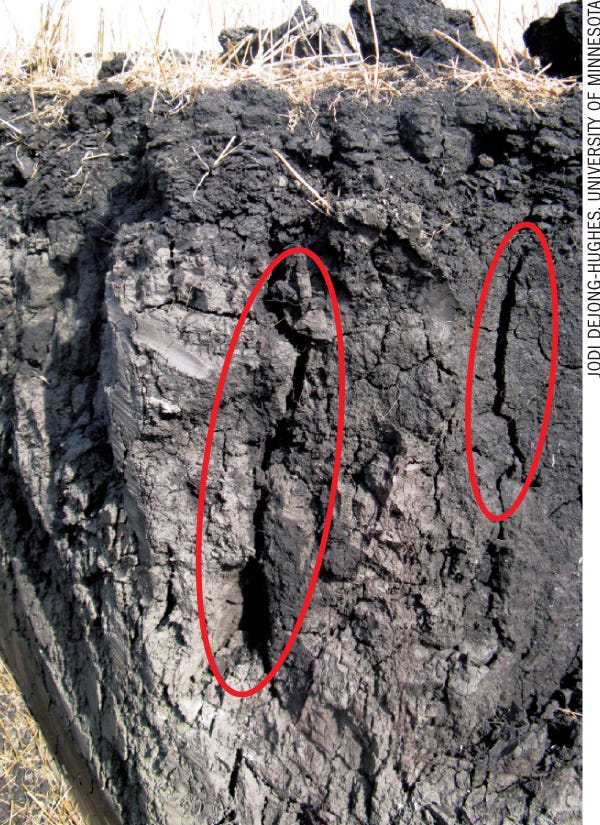

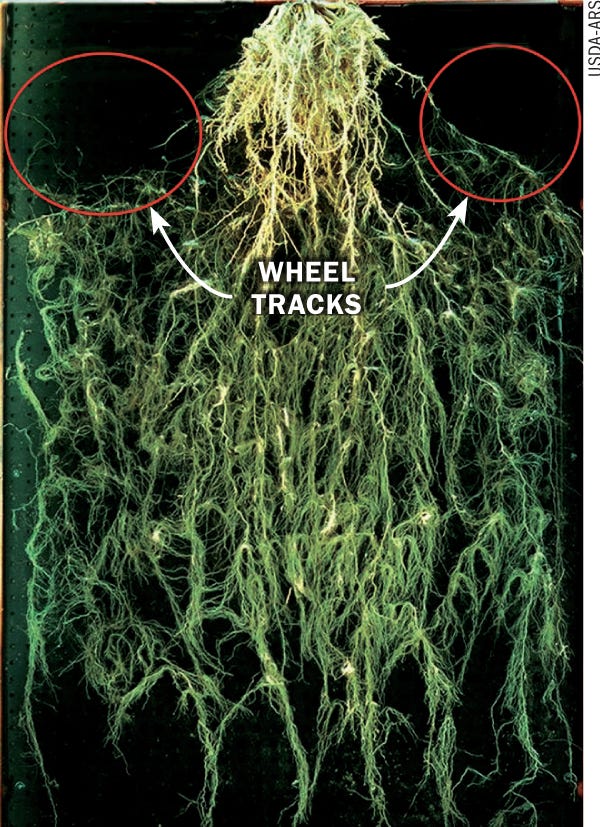

Regardless of soil type, root growth stops completely when soil penetration resistance exceeds 300 psi, as in these wheel tracks.

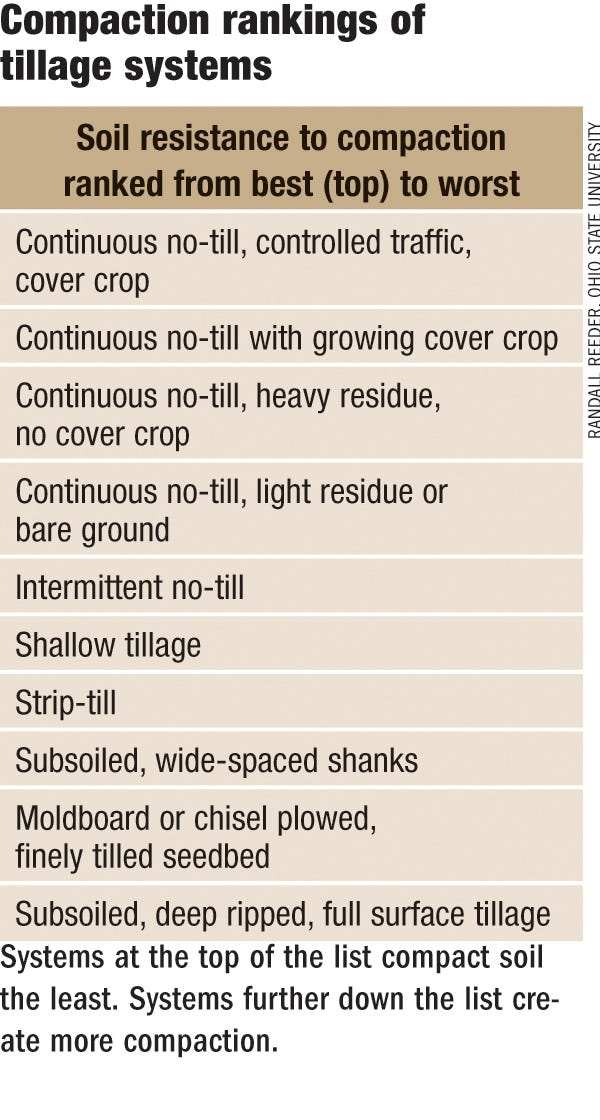

5. No-till soils resist compaction better than tilled soils.

Answer: True. No-till soils have better structure, higher organic matter content and greater biological activity than tilled soils, which makes them more resistant to compaction, Duiker says. However, “compaction can still have significant negative effects on the productivity of no-till soils.” In a Pennsylvania study, for example, no-till soil was compacted by a 30-ton manure truck with tires inflated to 100 psi. Corn yields fell by 30 bu./acre in a dry year and 20 bu./acre in a wet year, compared to yields in un-compacted no-till fields.

In Ohio State University’s continuing compaction research, annual subsoiling is being compared to continuous no-till. The plots have been compacted every three years since 2002. In the compacted plots (20-ton/axle load), no-till corn yields averaged 7% higher than subsoiled treatments, and soybean yields were 5% higher. The uncompacted control plots – no-till, only light traffic – yielded about 10% better than no-till compacted plots.

6. Limiting axle loads is the key to avoiding subsoil compaction.

Answer: True. “To avoid subsoil compaction, keep axle loads below 10 tons/axle,” Duiker says. That limits compaction to the top 10 or 12 in. of soil, where natural biological processes can help alleviate the damage. Reeder agrees: “Our compaction research includes 10-ton/axle loads. The yield loss is small, and usually disappears within two years.”

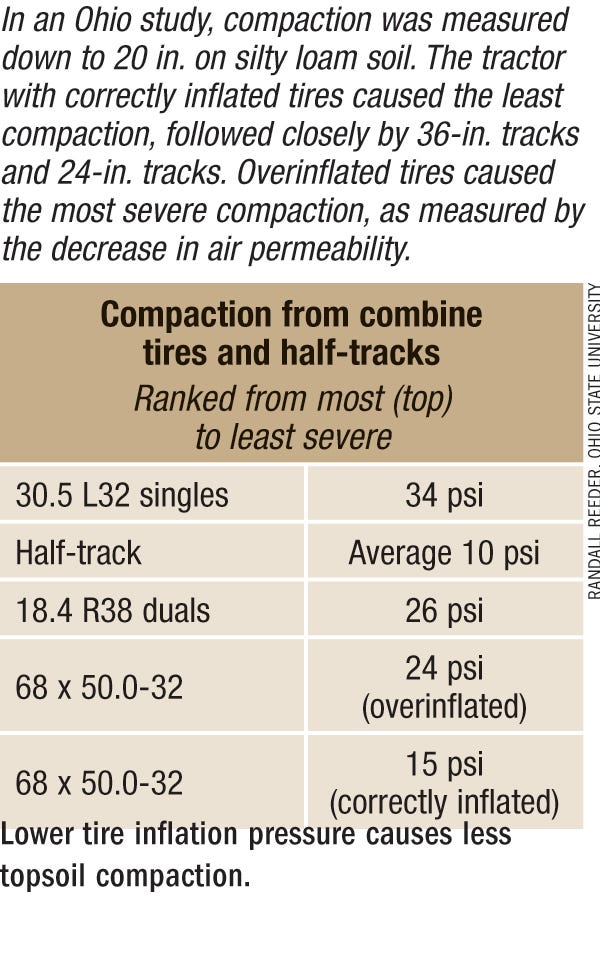

7. Tracks are better than tires for reducing soil compaction.

Answer: False. Tracks and properly inflated tires carrying the same load cause a similar amount of compaction, Reeder says.

One Ohio research project compared a half-track on a combine with several tire sizes and pressures. The average ground pressure under the track was around 10 psi, but it created soil compaction similar to tires inflated at 26-34 psi, Reeder says. Why? Pressure under the flexible track is not uniform, peaking under the front and rear axles, he explains.

In another Ohio study, dual tires correctly inflated to 6 psi resulted in slightly less compaction than tracks with an average pressure of about 6 psi. But the same duals over-inflated to 24 psi caused significantly more compaction than the tracks. Tracks do have some advantages over tires, Reeder adds, such as a longer, narrower contact area and less slippage. Tracks also have excellent flotation and no “power hop,” DeJong-Hughes says.

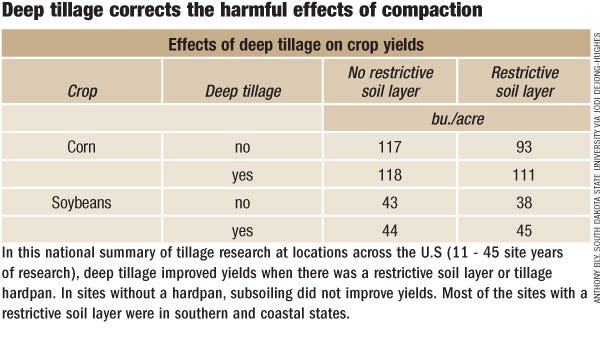

8. Deep tillage corrects the harmful effects of compaction.

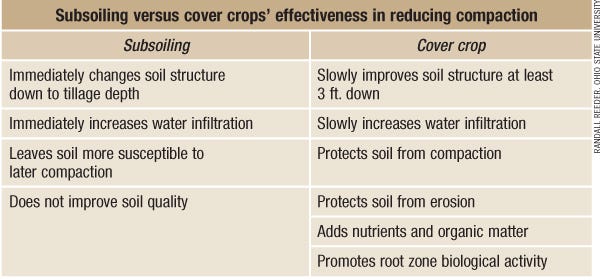

Answer: False. Deep tillage can shatter compaction layers created by wheel traffic or tillage, “but it doesn’t bring the soil back to normal,” Reeder says. And in the Midwest, “it has not been proven to increase yield consistently or for long periods of time,” DeJong-Hughes says.

“If we have a lot of compaction near the surface, subsoiling can temporarily alleviate it,” Duiker says. But it also increases the risk of future compaction, he says, setting up a damaging cycle of tillage and re-compaction that destroys the soil structure.

Subsoiling may be justified if you are changing from your old conventional tillage program to controlled traffic, Reeder says. In Ohio research from 1992 to 2002, subsoiling after compaction with a 20-ton/axle load raised corn yields about 3% and soybean yields about 10% compared to chisel plowing – provided there was no additional compaction.

If you do till deeply, DeJong-Hughes says, first determine where the compaction zone is and run the ripper about an inch under the bottom of the compacted layer. Work the soil only when dry – but not too dry. In fall 2011, she notes, soil was so hard and dry in southern Minnesota that tillage brought up huge soil clods. “Soil should fracture and crumble down to the depth of the shanks. Use the most non-invasive, straight shanks.”

9. You need ‘steel’ to alleviate compaction.

Answer: False. “There are biological solutions to compaction,” Reeder says. Cover crops, for example, can break up compacted soil. Plants like oilseed radish grow more than 2 ft. deep, creating channels and fissures for crop roots to follow the next season. Cereal rye is another deep-rooted cover crop that can penetrate compacted layers.

Growers in central Illinois are evaluating cover crops for several reasons, including the benefits of breaking up the compaction caused by wet seasons a couple of years ago, says Kelli Bassett, Pioneer field agronomist in Greenville, Ill. In fact, cover crop “seed availability this year was limited because of increased interest.”

Drainage improvements can help manage compaction, too, Reeder says, especially in low spots within fields that often get worked wet. So can more diverse crop rotations, which let growers “spread out field activities so there’s more opportunity to do field operations at the proper soil moisture,” Duiker says. “Tillage should be used sparingly to alleviate compaction when no other means can be used.”

10. Lowering tire inflation pressure reduces surface compaction.

Answer: True. The lower the tire pressure, the less it compacts the topsoil, says Ken Brodbeck, manager of Original Equipment and Export Sales for Firestone Ag Tires, Des Moines, Iowa. And the larger the tire, the lower the tire pressure needed to carry a given load. A larger tire at a lower psi has a longer footprint than a smaller tire at higher air pressure, which spreads out the load and reduces stress on the soil.

The proper tire inflation pressure depends on the tire size and axle load, Brodbeck says. Adding tires, or using taller or wider tires, reduces the carrying load per tire, allowing lower inflation pressure.

As the tire pressure decreases, so does the load-carrying capacity. Be sure to follow manufacturers’ recommendations so you don’t exceed the load-carrying capacity of the tire at that pressure. Ideally, Brodbeck says, you should run the vehicle over a scale in its heaviest condition to determine the exact weight before setting tire pressures. If that’s not practical, set the air pressure in the tires when the machine is resting on a firm concrete surface. When properly inflated, “one – or no more than two – tread lugs should be touching the concrete,” Brodbeck says.

Tire pressures are set for the heaviest load and road speed, DeJong-Hughes says. The optimum tire pressure in the field may be much lower, she says, but it’s impractical for farmers to change tire pressures for transport and field operations.

QUIZ: Assess your soil compaction risk

This quiz can help you get a better handle on a field’s compaction risk. The University of Nebraska assessment tool was adapted by Jodi-DeJong-Hughes, University of Minnesota. For each question, choose the response that best describes the situation in the field. Add up the points and see the rating at the end.

1. The organic matter of your soil is:

5 = low (< 1.5%)

3 = medium (1.5% - 3%)

1 = high (> 3.0%)

2. You usually do spring tillage:

5 = when you still carry a chain in case you get stuck

3 = when ‘it’s a little wet, but I’ll go anyway’

0 = when soil at the maximum tillage depth doesn’t slab

3. How often do you notice rows of stunted plants or delayed emergence where wheel tracks are obvious?

5 = most years

3 = in wet springs

0 = never

4. Is it getting harder to get yield responses despite high nitrogen soil test levels?

5 = yes

3 = occasionally

0 = no

5. Do you moldboard plow or disk?

5 = yes

0 = no

6. Do you run equipment axle loads exceeding 10 tons/axle on fields?

5 = yes, combine and primary tillage tractors

5 = yes, grain hauling carts or trucks

3 = just the combine

0 = no loads over 10 tons/axle

7. Does your ground crust after rainstorms? Do seedlings have difficulty emerging through the crust?

5 = most years

3 = occasionally

0 = rarely

8. Is your ground well drained?

5 = no

3 = partially

0 = yes

9. Do you perform plow, disk and harrow tillage operations before planting?

5 = always

3 = sometimes

0 = never

10. Do you begin spring tillage in the same field each year?

5 = usually

3 = depends on soil moisture of each field

1 = I rarely do spring tillage

Rate your risk

Less than 21:You are exercising good care in limiting compaction.

38 – 50 points:Do some serious digging into how much compaction you already have and how deep it is. Consider changing practices that add to compaction. Soil compaction may be limiting your yields in dry years.

22 – 37 points:Check for compaction pans. Remember that primary tillage or subsoiling is effective for breaking up compacted layers only when performed on dry soils. Afterwards, the soil is very vulnerable to re-compaction, so adjust your practices so you don’t abuse the soils in the future.

About the Author(s)

You May Also Like