Brian and Dan Sutton figured out how to vary rates on corn and soybeans on variable soils they farm in Lake County, Ind., even before commercial variable-rate equipment was readily available. They increase seeding rate for corn on better soils and drop it back on lighter, sloping soils. For soybeans, they reverse that and seed more soybeans on hills and fewer soybeans per acre on their most productive soils.

Once they moved into cover crops, they realized that it made sense to vary not only the rate they were seeding based on soil type, but also the type of cover crops. “We want to build as much organic matter as we can and prevent soil erosion on our lighter, sloping soils,” Brian Sutton explains. “That’s where we want cereal rye ahead of soybeans or annual ryegrass ahead of corn. And where soils need the most help on organic matter, we want to sow more seed.”

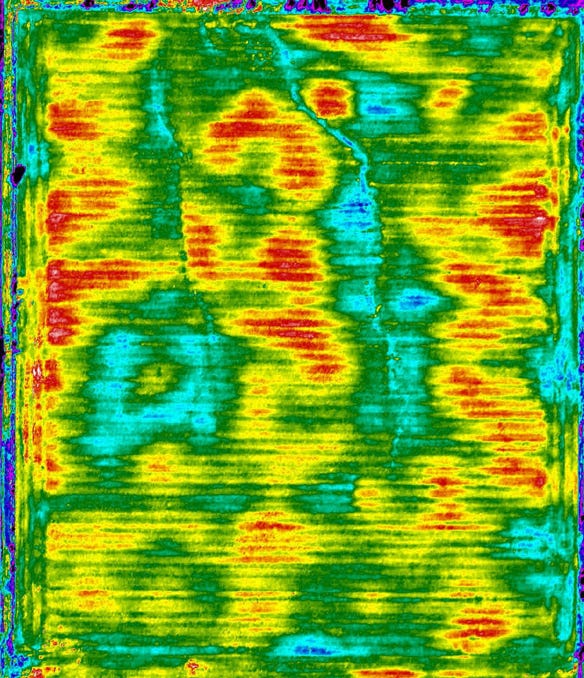

BARE SOIL MAP: This is a thermal-based image of bare fields taken by Brian Sutton, who heads up Air Scout. This was the image used to prepare the custom cover crop seeding prescription.

BARE SOIL MAP: This is a thermal-based image of bare fields taken by Brian Sutton, who heads up Air Scout. This was the image used to prepare the custom cover crop seeding prescription.

On their better soils, one of the main goals is capturing nitrogen left behind after the crop, Sutton says. They prefer to seed primarily brassicas, including radishes and turnips, in those areas.

Make it happen

Multi-hybrid planters are commercially available, and they knew how to vary rates, but how do you seed one cover crop species in certain areas of the field and an entirely different species in a different part of the field?

“We built a stainless steel cover crop seeder box with two compartments for seed,” Sutton answers. “We can lift out the spray tank from our high-clearance Hagie Air Scout machine and put the cover crop seeder in its place. It delivers cover crop seed to various sections across the 80-foot boom.”

Thanks to section control, they can be very precise in matching up which seed is placed where, and at what rate.

Writing a prescription to tell the machine what to apply where and at what rate was possible, since they already used similar technology with row crops.

In addition to farming, they operate Air Scout, a business that flies over farm fields and supplies proprietary images to farmers during the growing season.

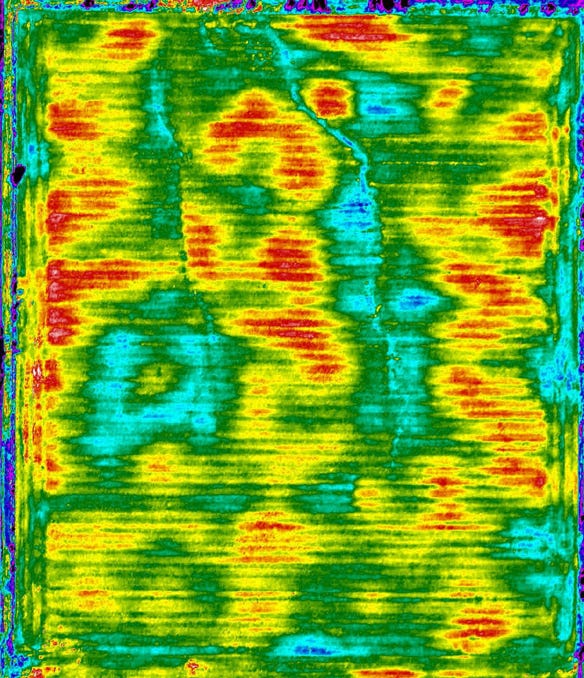

ONE-OF-A-KIND MAP: This prescription map Brian Sutton prepared from a bare soil image of the field can instruct the cover crop applicator device what product to apply where and at what rate.

ONE-OF-A-KIND MAP: This prescription map Brian Sutton prepared from a bare soil image of the field can instruct the cover crop applicator device what product to apply where and at what rate.

“We start with a thermal-based image of the field flown when the field was bare,” Sutton says. “It shows the differences in soil types very well. Based on that image, we can decide which cover crops should go where and at what rate. Then we build the prescription map so it can signal when changes should be made.”

You’re still dependent on the weather to get good cover crop stands, Sutton says, but when the weather cooperates, having the right seed at the right rate in the right places increases the odds of getting more payback from cover crops.

About the Author(s)

You May Also Like