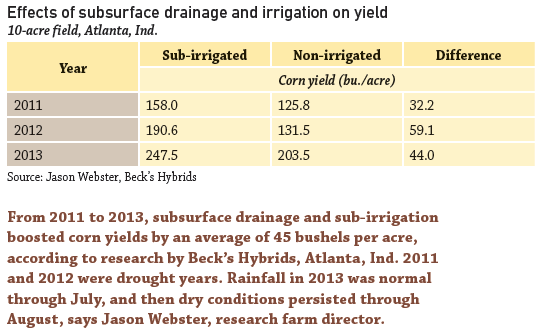

Think differentSub-irrigation under normal rainfallBeck’s Hybrids is testing a combined drainage and sub-irrigation system at its Atlanta, Ind., research farm. The 10-acre field, with a 3% grade, has 3-inch tiles on 15-foot centers. Drainage water flows by gravity into a holding pond at the edge of the field, which serves as the outlet. That water is pumped back into the field during the summer. The closed loop helps to keep the nitrates and phosphorus in drainage water out of surface waters, says Jason Webster, research farm director.From 2011 to 2013, the practice boosted average corn yields by 45 bu./acre. Even in 2013, when rainfall was closer to normal, yields in the sub-irrigated field were 44 bu./acre higher than the control field, Webster says. “We’re really impressed with the performance.

February 24, 2014

As soon as the Red River crested last May, North Dakota farmer Steve Miller opened the drainage outlet on a 108-acre tiled field, to dry out the soil.

In late June, Miller closed the outlet to hold moisture in the field.

And in July and August, he pumped water from the aquifer beneath the field back into the tile lines to irrigate the growing corn crop from below.

Miller’s “double duty” drainage and sub-irrigation system lets him control the water table in this field year-round. “I thought, if you can suck water out of the field, you should be able to pump it back in!” says the Fairmount, N.D. farmer, who grows corn, soybeans, wheat and sugar beets with his daughters, Alicia Holubok and Amanda Fisher.

The yield results have been encouraging, Fisher says. In 2013, which began with flooding and turned to drought, the sub-irrigated field produced 172 bushels per acre of corn following sugar beets, compared to 146 bushels in a comparable field in the same rotation, but without sub-irrigation. “It was one of our best fields in 2013,” she says. The crop received 7.8 inches per acre of water through the tile lines.

In on-farm, side-by-side comparisons from 2008 to 2010 — all good rainfall years — subsurface drainage and sub-irrigation boosted corn and soybean yields by 8% compared to conventional production, Fisher says.

Combining controlled drainage and subsurface irrigation offers “the best water-management in a wet or a dry year,” says Xinhua Jia, a North Dakota Extension agricultural engineer, who leads sub-irrigation research.

How it works

The Millers’ field is pattern-tiled with 4-inch laterals on 30-foot centers, placed 3-4 feet deep. Sixty-foot spacings would be sufficient for drainage alone at this site, Jia says, but closer spacings are needed for efficient sub-irrigation.

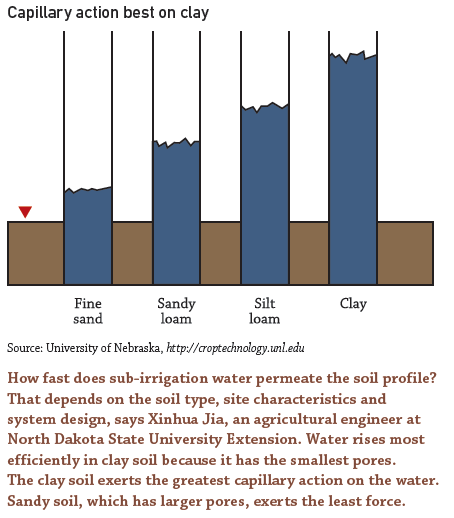

Drainage water flow is controlled by a sump-pump outlet, which is turned on in early spring and late fall to lower the water table, and shut off in summer and winter. The same sump-pump system pushes water back into the pipes in mid-season for subsurface irrigation. Water seeps out of the tile, permeating the soil through capillary action. Two pumps and wells are needed to achieve uniform water distribution on the field, which slopes 0.14%. The entire system cost about $2,000 per acre, Miller says.

Boosting value of drainage investment

Last spring, Dan Strong installed controlled drainage and sub-irrigation on a 200-acre farm near Lawrence, Kan. Erratic yields and surface water pooling showed the need for improved drainage on the flat, heavy-soiled ground. But the cost of tiling this farm was prohibitive “unless we combined it with subsurface irrigation” to increase potential crop yields and returns, Strong says.

The combined system includes 4-inch laterals on 20-foot centers, plus 10 outlet-control structures with movable risers that raise and lower the water table. Cost of the system, including two irrigation wells, was “in the low $2,000s per acre,” Strong says.

That’s roughly the same as the cost of a conventional drainage system plus surface irrigation, says Mike Tveten, a drainage engineer at Ellingson Companies, West Concord, Minn., which designed and installed Strong’s system.

“The drainage system will be a benefit every year,” Strong says, allowing timely planting and harvesting. “The irrigation benefits will vary with the year.” However, the region is in a drought cycle, he adds, and water allocations are restricted.

Low water use, but steep learning curve

The potential water savings from subsurface irrigation are very significant, says Mike Aide, who leads sub-irrigation research at Southeast Missouri State University. “This is a low water usage practice.” Center-pivot irrigation systems may lose up to 50% of water to evaporation or runoff, he says. With sub-irrigation, “all the water is at the root zone,” so there’s no waste. There’s less maintenance than with a center-pivot system, too.

But subsurface irrigation management is more challenging than surface irrigation — for an obvious reason, Aide says: “You can’t see where the water is going!”

Water distribution may not be uniform across the field, says Jia, the North Dakota engineer. “The water table will be higher at the lower parts of the field and where water enters the system.” Especially in the beginning, “we don’t know how far water will move in the field.”

The Kansas farmer monitored the water table in his sub-irrigated field by taking an ATV around the field and looking into the stop-log structures to see how high the water was on the upstream side. Miller, the North Dakota farmer, used electronic soil-moisture sensors, but “there’s a lot more to it than I thought,” he says. Aide agrees: “There’s a learning curve. You need to develop a gut feeling on how the crop responds. It takes close watching.”

You also need to start sub-irrigating “before you think you need it,” Tveten says. The best strategy is to maintain a static or “perched” water table at about 3 feet below the surface, Aide says. That takes a different mindset than aboveground irrigation, “where we let the soil dry down and then re-wet.” At the Missouri sub-irrigation research site, Aide pumps about 2 gallons per acre per minute all summer, except when it rains. In 2012, a severe drought year, the sub-irrigated field made 196 bushels per acre of corn and 52 bushels per acre of soybeans; non-irrigated fields yielded almost nothing.

Is subsurface irrigation an option for your farm?

Combined subsurface drainage and irrigation systems are common in the eastern U.S., but the practice is new to the Midwest. Requirements include:

Water source. Water for sub-irrigation can be pumped from an aquifer, artesian well or seep, drawn from a public ditch or river, or collected in a reservoir and recycled.

Flat terrain. “The flatter, the better” for maintaining a uniform water table, says engineer Mike Tveten, Ellingson Companies, West Concord, Minn. “A slope of less than 0.3% is ideal,” he says. “You can do it on more rolling terrain,” but extra drainage control structures will be needed, pushing up the cost, he says.

Restrictive soil layer. “For this system to work, you need a restrictive layer below the tile depth to keep water in the field,” says Mike Aide, who leads sub-irrigation research at Southeast Missouri State University. Soil hydraulic conductivity should also be measured before a system is designed.

Narrow tile spacings. For efficient sub-irrigation, tiles must be spaced about 40% closer than for subsurface drainage alone, says Xinhua Jia, North Dakota State University irrigation expert. Existing pattern-tile drainage systems can be retrofitted for sub-irrigation, she adds. Steve Miller, a farmer from Fairmount, N.D., tried sub-irrigation through tiles on 60-foot centers, “but it took too long, and wasn’t uniform enough.” Miller added laterals between the existing drains, as well as a second well and controlled outlet.

Drainage outlet controls. Controlled outlets raise and lower the water table under the field. These can be pumped outlets, which are turned on and off, or stacked flashboard risers in the tile mains that are adjusted manually or electronically. The outlet controls keep water in the field during the growing season and the winter fallow period. In turn, that cuts nitrate loads flowing into surface waters along with the tile effluent. “It’s a win-win for farmers and watersheds,” Jia says.

About the Author(s)

You May Also Like