March 19, 2020

The John Deere 495 and 494A planters were classics. Oliver was proud of its planter. Case thought its planters were a good fit. And Allis-Chalmers offered planters that meshed well behind its tractors.

Those planters of the 1940s, 1950s and 1960s were a big step forward from two-row horse- or tractor-drawn planters.

So, before you head off this planting season to dial in prescriptions to change seeding rate and maybe even hybrid by soil type, look at the planters that paved the way. Each of these was the pride and joy of someone’s grandpa:

John Deere 494 Series. The four-row 494, 494A and 495 planters used seed plates to singulate seed. No one really referred to it that way back then. They were more concerned with getting the right size and grade of seed so the individual seeds would fit within the cells — first on metal plates and then later on plastic plates. Once plastic plates came around, if you were good friends with your seedsman, he would likely supply you with the plates you needed for the grade of seed you planted.

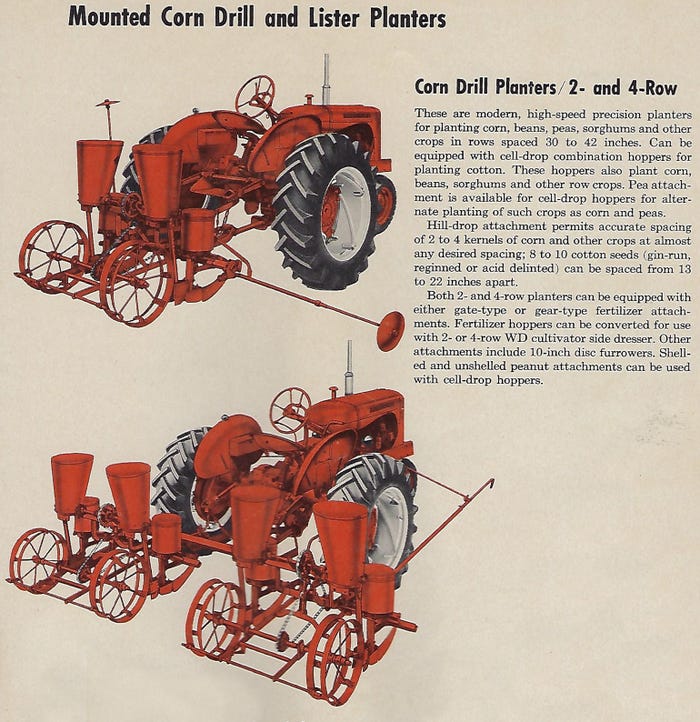

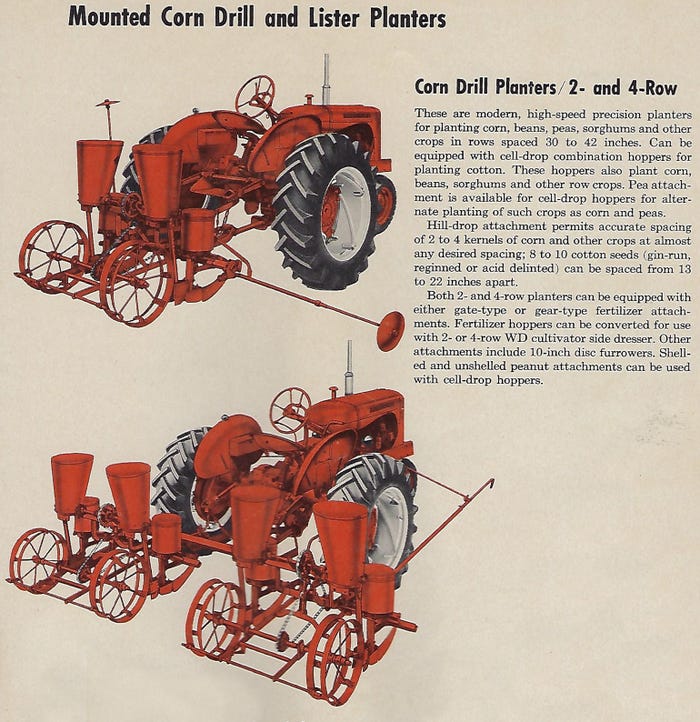

Allis-Chalmers corn drills. You could get a two- or four-row, mounted corn drill planter spaced at 30 to 42 inches. If you still wanted to drop in hills, you could order the planter with a hill-drop attachment, and place two to four kernels of corn per hill. And if you wanted to apply starter fertilizer while you planted, you could get either gate-type or gear-type fertilizer attachments. Buy the right attachments, and you could plant cotton and peanuts with these planters.

You could also get front-mounted, two-row planters that fit on the standard WD two-row, mounted cultivator frame. The No. 2 four-row AC planter also offered transparent seed tubes so you could see seed as it dropped — perhaps the earliest seed monitor!

CORN DRILL: Allis-Chalmers still used the term corn “drill” for some of its planter models. They could be adapted for hill dropping and planting other crops, including peanuts and cotton.

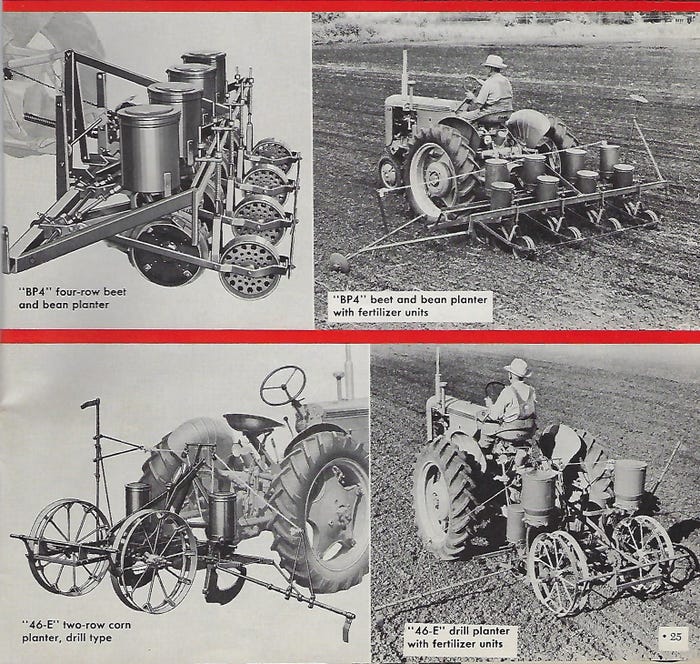

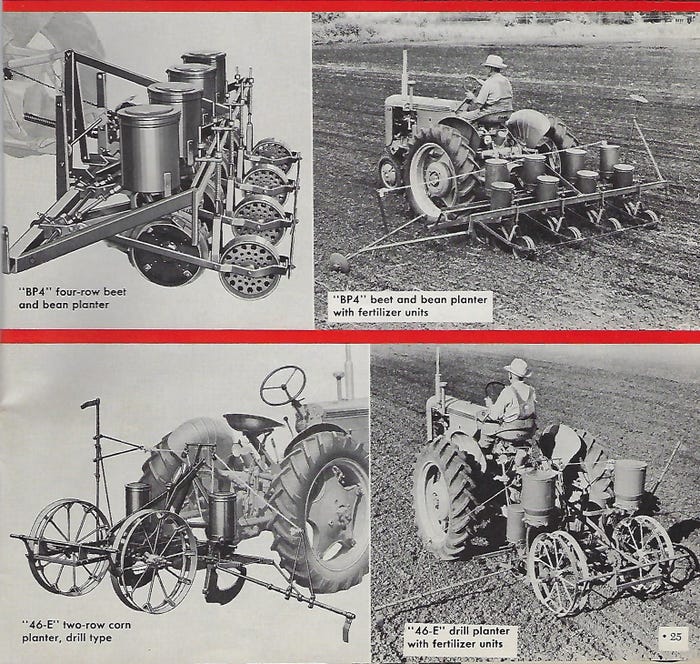

Case Eagle Hitch planters. Allis-Chalmers had the Snap-Coupler; Case had the Eagle Hitch. The result was the same: a mounted planter. You could still check-row corn, or “drill it” with the two-row 45-E Case planter, and drill with the 46-E. The 45-E check-row model came with 80 rods of wire. Talk about technology!

Case also built and sold the BP4, a “beet and bean” planter. Fertilizer attachments were available.

MOUNTED PLANTER: These Case planters mounted to the Case tractor using the Case Eagle Hitch system. One planter model still came with 80 rods of wire for check-row planting.

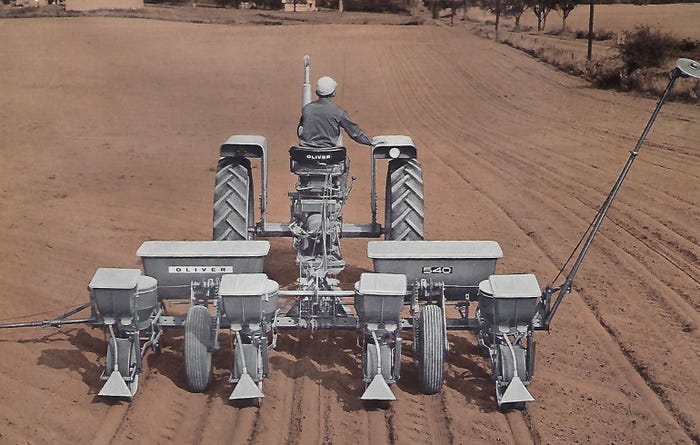

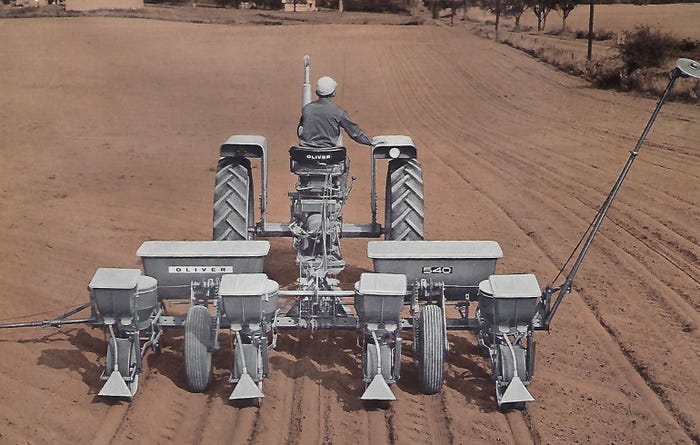

Oliver 540 planter. Moving into the 1960s, Oliver offered the 540 corn planter. Perhaps it was ahead of its time. Literature promoting the planter says you could plant up to 8 miles per hour. That’s if you were willing to space seeds 12 inches apart — honest, that’s straight from the brochure. And it might have worked because you could drop two to three kernels per hill. To get up to 120 acres planted per day, Oliver recommended hooking up two four-row 540 planters on an Oliver Twin Hitch.

NEW FOR ITS TIME: You could plant 8 miles per hour with this Oliver 540 planter — if you spaced seeds 12 inches apart.

Comments? Email [email protected].

You May Also Like