Heavy snow is nothing new to farmers in New York, Pennsylvania or other areas of the Northeast. But there are proper ways of dealing with these heavy snow loads, especially when it comes to removing snow from barn roofs.

You may be wondering whether your pole barn is up to the task of handling a big snowfall, especially if you’re in an area where these snowfalls are normal. Building failures from snow loads can be attributed to several factors, including improper building design and construction, actual snow load exceeding designed snow load, and imbalance of snow load on the roof.

“The biggest reason why barn roofs fail is because of lack of complete load transfer from the roof to the foundation footing,” says Curt Gooch, senior Extension associate at Cornell Cooperative Extension. "The lack of complete load transfer is largely due to lack of barns being structurally designed using a procedure to ensure complete load transfer. In most cases, ag barns are exempt from build code, thus they lack complete structural design being employed."

Pre-engineered post-frame agricultural buildings are typically designed to withstand a certain level of wind and snow loading, and should withstand any snow loads that are below the “design value.” For example, if the snow load is 30 pounds per square foot, and it was designed for 40 pounds per square foot, then there shouldn’t be a problem.

Older buildings, however, may not have been designed that way, so they’re of concern.

Andrew Schmeider, a licensed civil engineer from western New York who designs many types of agricultural buildings, says there are several ways to address heavy snow loads when designing a pole barn or other ag building — or if you’re interested in reinforcing a building.

For new buildings, one way is to increase roof slope to ensure snow loads don’t accumulate as much. Another is to decrease truss spacing from the typical 48 inches to as narrow as 2 feet.

Putting enough space between new buildings, Schmeider says, is another key.

“One of the main causes of snow-related roof failures is when snow drops from one roof to an adjacent roof. … We try to maintain a minimum of 5-foot separation between buildings to minimize impacts from snowfalls,” Schmeider says.

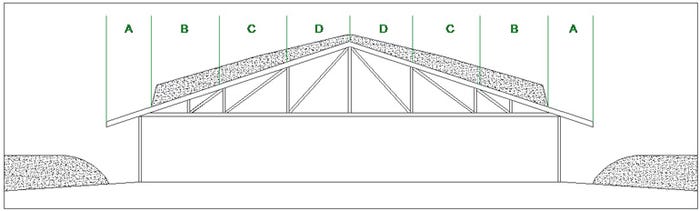

Use a zoned approach to remove snow from a barn roof. The number of zones depends on the width of the barn or the span of the trusses.

Existing buildings are seldom retrofitted unless they’ve incurred some damage from snowfall, he says, or if a producer just wants to be proactive, but this can be costly.

“A couple of years ago, a roof was severely damaged due to heavy snowfall, and snow loading from one roof dropping onto another. In this case, the damaged rafters were replaced, and the existing roof trusses were reinforced,” Schmeider says.

“Probably the best way to increase load-carrying capacity of existing roof systems is to reinforce the existing rafters or trusses. Typically, it's the joints that fail, so these need to be inspected and reinforced as well. When retrofitting for larger snow loads, you have to look at header-post and all load transfer members to make sure they can take the additional loading as well. Structure is only as strong as the weakest link.”

Signs of failure

So, how can you predict if a pole barn or other building is going to fail? For a pre-engineered building, check the actual snow load on the roof against the design snow load.

Wood structures will show stress before they fail, so listen or look for the following signs:

● creaking or moaning in the building

● bowing of truss bottom chords or web members

● bowing of rafters or purlins

● bowing of headers or columns

If these signs are present, consider evacuating animals from the barn, and evacuate people from the structure.

Pre-engineered metal structures will most likely fail without warning.

Do’s and don’ts of shoveling

Many farmers will shovel the snow off the barn roof to save their building from collapsing. But this should be done only by experienced people who are properly trained and protected against a fall.

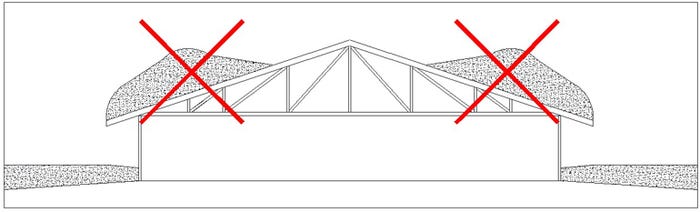

Shoveling the roof without the proper approach can cause more damage by creating an unbalanced load on the roof.

Removing snow unequally from a barn roof can cause unbalanced loads. If snow is piled over smaller portions of a roof, rather than spreading the load equally, structural failure is more likely.

With that, here are some do’s and don’ts from Cornell Cooperative Extension of shoveling snow from a barn roof:

Do’s

Remove snow using a systematic, zone removal approach. The number of zones depends on the width of the barn or the span of the trusses, but in all cases, snow removal should start with the eave areas.

Remove snow from both sides of the barn as equally as possible. As snow is removed from the roof, be sure to remove snow from the barn sidewalls as deep snow piled against the walls can cause barn failure and ventilation issues.

Continue working toward the roof peak, removing snow in a systematic and balanced approach until all snow is removed.

Don’ts

Remove snow unequally from a barn roof. Unbalanced loads can cause the unloaded side of a truss to lift, possibly compromising the connection at the post. Work back and forth from side to side as you remove snow, or better yet, use a crew on each side simultaneously.

Pile large piles of snow atop the roof. A structure may be able to support a snow load when it is spread equally, but once loads are combined over smaller portions of the roof, structural failure is more likely.

About the Author(s)

You May Also Like