February 12, 2015

Stan Guyer is a second generation family owner of Moridge Manufacturing based in Moundridge, Kan. that's already bringing in third-generation family members to the business. And they're known not as Moridge Manufacturing, but as Grasshopper Mowers. That's not the product they first had on display when the National Farm Machinery Show opened its doors 50 years ago.

"Back then we made grain dryers and spring-tooth harrows," Guyer says. "I even found a Louisville newspaper article with a photo of a child looking through the curtain during the show at our harrows."

Stan Guyer, a second generation family owner of Moridge Mfg., Moundridge, Kan., celebrated his status as one of the original exhibitors at the National Farm Machinery Show.

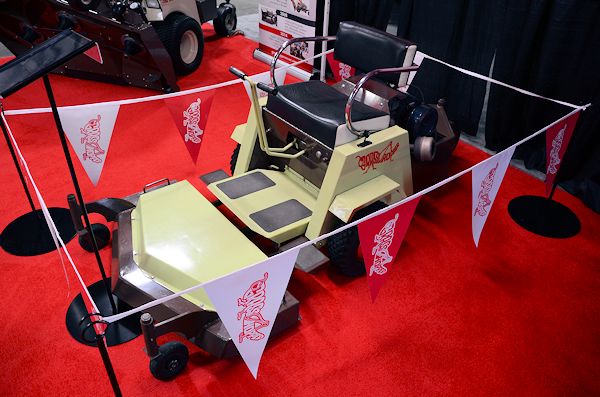

During this year's show, Grasshopper had an original model zero-turn mower on display to celebrate the show's golden anniversary. Yet how did a grain dryer/spring-tooth harrow manufacturer make the transition to be a leading maker of zero-turn mowers? It started with the first mower.

"We were looking for a spring product," Guyer recalls. "We were a struggling company back then with grain dryers and spring tooth harrows. We looked at a lot of different ideas, but we needed a spring product."

The zero-turn mower concept was developed in Moundridge, Kan. and it Grasshopper can lay claim to bringing the first commercially available product to market. Another zero-turn maker, Hustler is located in the same area and was developing its own concept at the time.

Moridge Mfg., got its start building products on the farm in Osborn County. Guyer says his playground was the farm and a manufacturing plant. Farmer innovators know what their customers want - a durable machine they can count on. And that's what has guided Grasshopper since that first mower rolled out of the factory.

Guyer recalls the early days of mowers with cone drives. "We had durability issues," he says.

While farmers were early customers for those zero-turn mowers, the company branched out pretty fast after 1969 and commercial users - like groundskeepers and others - put those mowers to the test. "In 1973 we made the move to hydrostatic drive with the swing out handles," Guyer says.

Those two innovations, in tandem, put the mower on the map. The swing out handles make it easy to get on and off the mower, and hydrostatic drive proved itself durable in a wide range of uses. "We have a 10,000-hour club," Guyer says. "It includes members that have machines with 10,000 hours or more and still operating."

And what about those grain dryers? Turns out the farm implement business was pretty competitive, and Guyer notes the company was also left behind in the dryer business when corn hybrids evolved to have better drydown. He tells a story that typifies the evolution of the business. "I was talking with a customer, in a wet year, about putting in a grain dryer and he just wouldn't make the investment. That dryer would have paid for itself in the first year," Guyer recalls. "He wouldn't buy, but as we were walking out, he called me back and asked me about 'those Grasshopper' mowers."

This is the mower that changed it all for a farm implement maker. The one of the left represents the first model year for Grasshopper Mowers which debuted in 1969. The model on the right is one of the latest machines offered by the company.

Guyer says that was an indication of where the market was going.

The company has continued to innovate its mowers. They put air-cooled diesel engines on the machines, but found those weren't durable enough. The next move was an industry first: "We were the first to use the liquid-cooled diesel in a commercial mower application," Guyer notes.

He explains that Moridge Mfg., likes to test products and works closely with suppliers and vendors to build new products. For example, the company shares a patent with Parker Hannifin, the hydrostat maker. And the company went one step further six years ago.

"We were not happy with the hydrostatic oil we had available," Guyer says. "So we developed our own oil." You read that right, they developed their own oil. Working with a petroleum batch formulator they eventually developed a product that allows them to provide 1,000-hour intervals between hydrostat oil changes.

Guyer proudly talks about where his product is used. "They use a Grasshopper at the White House," he says. And there's even a machine - with no mower deck - that clears snow off the sidewalk of the George Washington Bridge in New York City. The zero-turn design combined with a snow blower can apparently just get right out and clear the walkway on the bridge. Of course that machine is getting a real workout this winter.

I like talking to equipment company owners, who grew up in the business. The pride they have in their product shines through. Grasshopper Mowers have had a solid ride in the market and they continue to innovate too. Even though the key product isn't a farm implement anymore, the company maintains that farm-type innovative focus.

You May Also Like