Making hay when the sun shines has been an important farm task for generations, but haymaking has gotten easier.

A job that once took several hands in the field to accomplish has been made into a one-person job, thanks to the baler. These days, you don’t even need a tractor to pull a baler, with self-propelled round balers on the market.

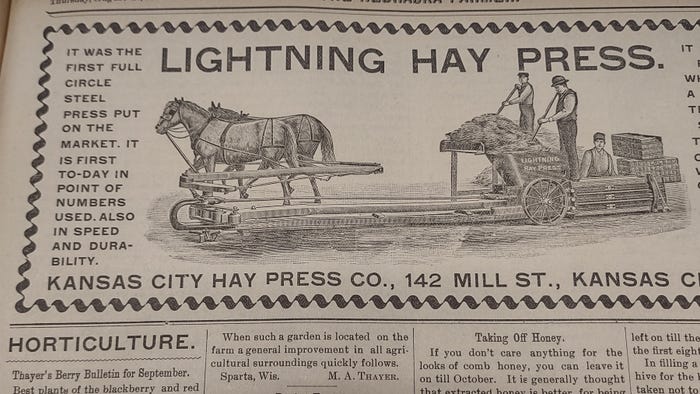

But if we look back almost 130 years, haymaking — particularly putting up small bales of hay that could easily be shipped or fed to livestock — was something new. There was an ad in the Aug. 27, 1896, issue of Nebraska Farmer, promoting the new steel Lightning Hay Press, manufactured by Kansas City Hay Press Co.

LOOKING BACK: This ad for a horse-drawn hay press was published in the Aug. 27, 1896, issue of Nebraska Farmer.

Strong and durable

Placed on the page above stories about berry farming, collecting honey and purchasing trees to plant, the ad for the horse-drawn unit says, “It was the first full circle steel press put on the market.” The ad touts the hay press for its speed and durability.

Looking back at a Mississippi Agricultural Experiment Station Bulletin on hay presses, published in June 1889, there is a description of the Lightning Hay Press and others on the market at the time. The bulletin notes that hay presses and the small bales made by them offer farmers an opportunity to ship hay by rail much easier.

The agricultural station in Mississippi invited numerous hay press manufacturers for an exhibition day, and wrote in the bulletin about the differences between the presses that took up the invitation.

About the Lightning Hay Press, the manufacturer wrote in the bulletin, “We have a full circle sweep, which dispenses with the expensive assistance of a driver, a vast improvement over the old, cumbersome, awkward half circle.”

The report noted the steel composition of the Lightning Hay Press, and its superiority over wooden models. The bale chamber, main bearings and pins were all made of steel. This fact, it was noted in the report, allows farmers to bale almost anything, including higher-moisture forages and hay, wool, cotton, or other materials that needed to be packed into burlap for shipment.

Faster than the rest

Along with the Lightning press, other hay presses exhibiting included the Ideal Press by Progress Manufacturing, Hamilton Press by Southern Standard Press Co., and the Hunter Press by Jacob Holberg and Son, all based in Mississippi. Lightning was the only press demonstrated that was not from the home state where the ag station was located.

At the conclusion of the demonstrations, bales were weighed and judged by staff at the experiment station. It was noted that the Lightning completed its demonstration in less time than any other press. The bales were good, the report said, but not as smooth as the other presses. The cost of a Lightning Hay Press at that time was more expensive than the others at $310.

Over the years, Kansas City Hay Press Co. eventually got into producing gas engines. Their hay presses advanced too, operated by gas engines, instead of real horsepower. The company briefly made tractors as well.

While modern balers are marvels in the field that we often take for granted, the steel, horse-drawn Lightning Hay Press was just as cutting edge to farmers of the day almost 130 years ago.

Read more about:

HayAbout the Author(s)

You May Also Like