At a Glance

- Costs for new grain storage and grain handling facilities shot up over the past two years.

- Expenses besides the bin itself, including higher interest rates, impact decisions.

- Past building opportunities are history — what about future costs and options?

Off-farm grain storage options are drying up in John and Kristi Kretzmeier’s area near Fowler, Ind. The Kretzmeiers don’t have on-farm storage because they have invested in other opportunities, relying on off-farm storage until now.

“Grain bins are much higher today, but it’s not just the cost of bins that matters,” John Kretzmeier says. “All the other costs add up: site preparation, concrete, electrical work and labor to erect legs and other structures.

“Then you have operational costs like electricity, propane and labor. You’ve also got property taxes to consider. Plus, interest costs are higher now.”

Today’s grain bin economics

Kretzmeier’s homework indicates it would cost $9 to $10 per bushel to start from scratch and build a workable grain center to meet all their grain storage needs. They will likely pass and make other adjustments.

STORAGE: John and Kristi Kretzmeier will fine-tune marketing skills and farm without grain bins, even as off-farm storage options shrink.

What if you just need extra storage space, or perhaps extra space plus additions to an existing grain center?

Industry experts put the cost of a new bin with concrete foundation at around $3 per bushel of storage capacity. Add in electricity and other costs, and sales specialists put the figure at $3.50, headed toward $4 per bushel. That doesn’t include a dryer or augers to get grain into the bin.

One producer in west-central Indiana committed to adding two bins this year because off-farm storage disappeared. His final costs with electricity, figuring on filling bins with augers, will be just over $4 per bushel.

Pull the trigger on new bins

Tom Nugent, Elnora, Ind., farms with his son Thomas. “We needed a larger bin, but we also needed a bigger pit to increase efficiency in the fall,” Nugent explains. “Since Thomas wants to keep farming, we invested in the system.”

Completed late last fall, the addition includes a 145,000-bushel bin; a 10,000-bushel wet-holding bin; a new pit for unloading; a second, higher-capacity grain leg; and a building over the pit.

“Our existing dryer will need replacement soon, but we concentrated on adding storage and efficiency this time,” Nugent says.

The Nugents did the dirt work themselves, hauling dozens of loads of soil from a sand hill to the bin site. “Even doing earthmoving and other projects within our skill set ourselves, it still was an expensive project,” Nugent says.

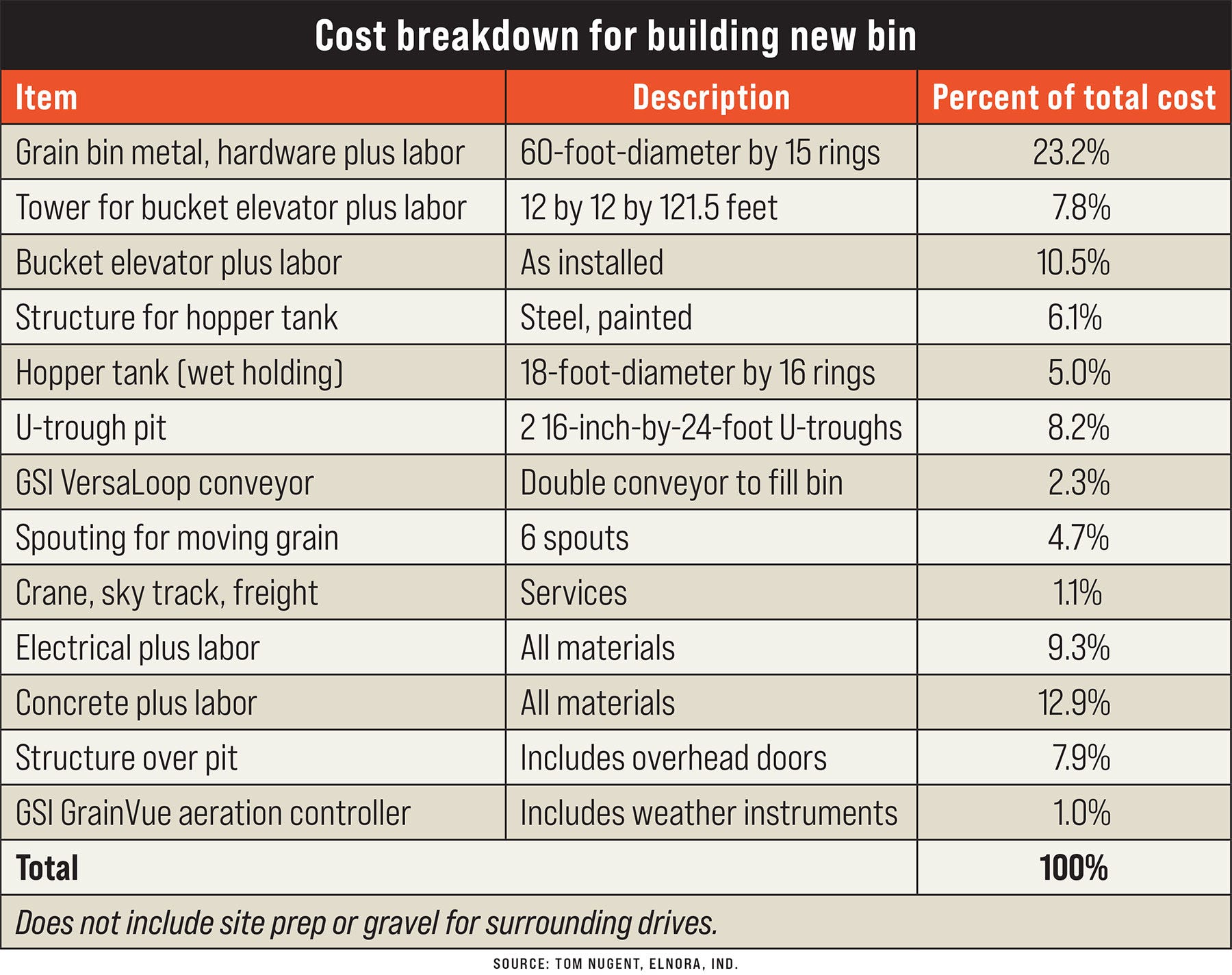

How expensive? Final cost pencils out around $7 per bushel of added storage space, counting all costs except their own labor. Nugent shared his invoices. Review the table below to compare cost of various parts of the project on a percent basis.

Build grain storage now or wait?

If you’re going to add capacity, should you bite the bullet and build now, or wait?

“I recently spoke with a couple growers who put bins up in 2020,” says Jim Luzar, Purdue Extension agricultural educator in Clay and Owen counties in Indiana. “They were amazed by price increases today. Both said they spent around $2.50 per bushel of storage capacity for ready-to-use storage then.

“Here’s the kicker. One contractor told me it is almost too late to order a bin ready for fall 2024.”

Whether you could get bins erected by this fall could depend on factors in your local area. Most manufacturers say bins are available. The big “if” is whether the company erecting your bin could tackle it in time. In east-central and southwest Indiana, where storms wrecked numerous bins and facilities this spring, it might be difficult.

LOCAL OPTIONS: The farmer driving this truck still has a large co-op elevator where he can deliver and store grain, even though this is a small town. However, not everyone has that option.

“It takes time, especially if you’re also adding a leg and wet holding bin,” Nugent explains. “We started talking with the builder in November 2022, signed a contract in December, and the bin wasn’t finished until late October 2023. In fact, we were wrapping up harvest. And we’re still adding finishing touches.”

Regardless of timing, Nugent is glad he pulled the trigger to build when he did. “We should have done it five years ago, but other factors didn’t line up,” he explains. “So, costs were about double what they would have been earlier.

“But I looked at what costs might be if I waited another five years. Hopefully, they will not double again. But odds are they would be higher. Looking to the future with Thomas in mind, it was the right decision.”

Bagged grain provides bin alternative

Nathan Mayfield and his father, John, of Athens, Ill., have been storing grain in bags for years as an economical alternative to building new grain infrastructure.

“Our yields started getting high enough to where we needed more storage than what we had on the farm,” Mayfield says. “That’s when we started researching grain bagging — but nobody else in our area had tried it.”

In 2018, Mayfield rented a grain bagger and bought some grain bags. It worked without a hitch, and he’s since purchased a grain bagger and extractor.

Mayfield says the benefits of bagging grain outweigh any negatives, but recommends farmers consider certain factors before taking the plunge.

Benefits:

economical alternative to new bin infrastructure

flexibility to take advantage of runs in the market

harvest efficiency because combine never stops

decreased harvest labor by eliminating hauling to bin site and auger unloading

decreased maintenance compared to a bin site

Considerations:

You need a level, well-drained area for the bag to sit.

Unloading grain in inclement weather can be difficult.

Rodents and deer can rip bags, resulting in spoilage.

You need an extra tractor with a PTO, plus a bagger, an extractor and bags.

Pre-COVID-19, custom bagging rates were 10 cents per bushel to bag and 10 cents per bushel to extract, plus the cost of the bag itself.

“Custom rates have gone up since then, but that should be more than enough to cover machinery costs in today’s economy, considering depreciation, fuel and repairs, if you’re doing more than just a couple bags,” Mayfield says.

The cost of a 10-by-300-foot, single-use, 14,000-bushel bag is $900 to $1,200, or 7 to 8 cents per bushel. The price of a bagger and unloader varies depending on brand and age, but any tractor around 100 hp or less can run the equipment.

“We really enjoy bagging and plan to keep doing it,” Mayfield says. “It saves us from having to pay more on taxes and the price of a grain bin itself.”

For more about the changing commercial grain landscape and closing elevators, read The local grain elevator closed. Now what?

About the Author(s)

You May Also Like